Smoke distribution device in electric dust removal air inlet hood

A technology of flue gas diversion and air intake hood, applied in the direction of electrostatic separation, steam flow control, etc., can solve the problems of uneven air distribution, incomplete ash release, poor dust removal effect, etc., achieve uniform distribution, prevent secondary dust, The effect of reducing turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific example the present invention will be further described:

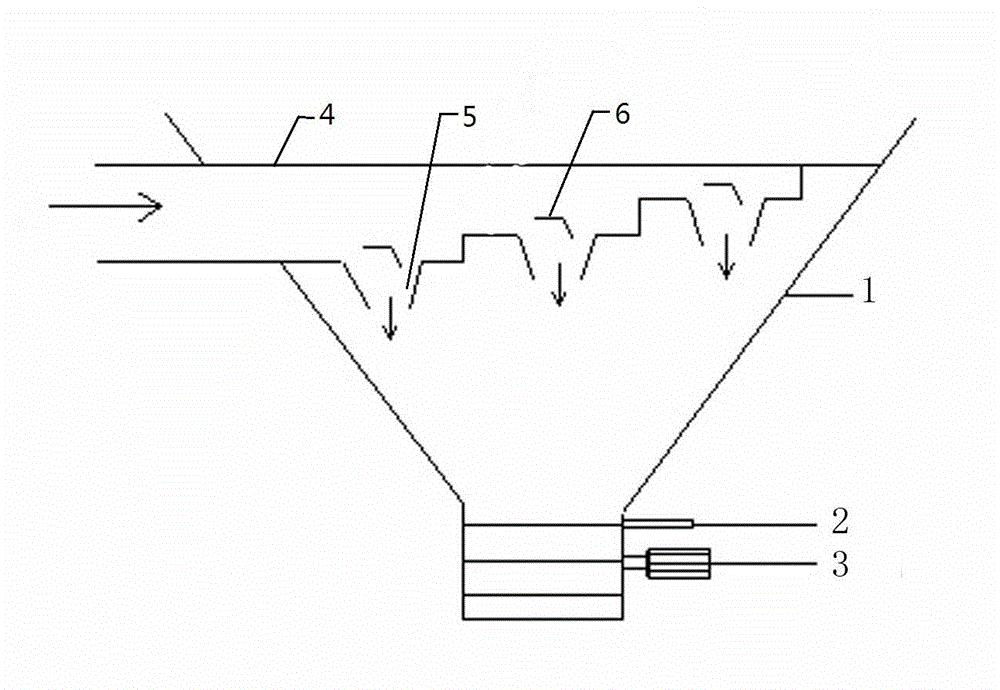

[0014] Here, the V-shaped splitter plate combined with the orifice plate is used to adjust the airflow of the electrostatic precipitator into the mask, so as to achieve the purpose of optimizing the airflow distribution in the dust collection area. The three-dimensional airflow distribution in the electrostatic precipitator is calculated by using the numerical simulation method, and the method of adjusting the airflow distribution by using the porous plate alone and the combination of the porous plate and the V-shaped shunt in the electrostatic precipitator project is compared, and a V-shaped air flow is proposed. The advantages of splitters in regulating the airflow of electrostatic precipitators.

[0015] The device includes an air inlet splitter main pipe, a splitter plate, and an air inlet manual regulating valve. The role of the splitter plate at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com