Finished product quality detection equipment for mask production and detection method thereof

A quality inspection method and technology of inspection equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of pulling damage of qualified parts, damaged defective parts, inconsistent inspection strength, etc. Large contact surface, increased clamping tightness, and enhanced clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

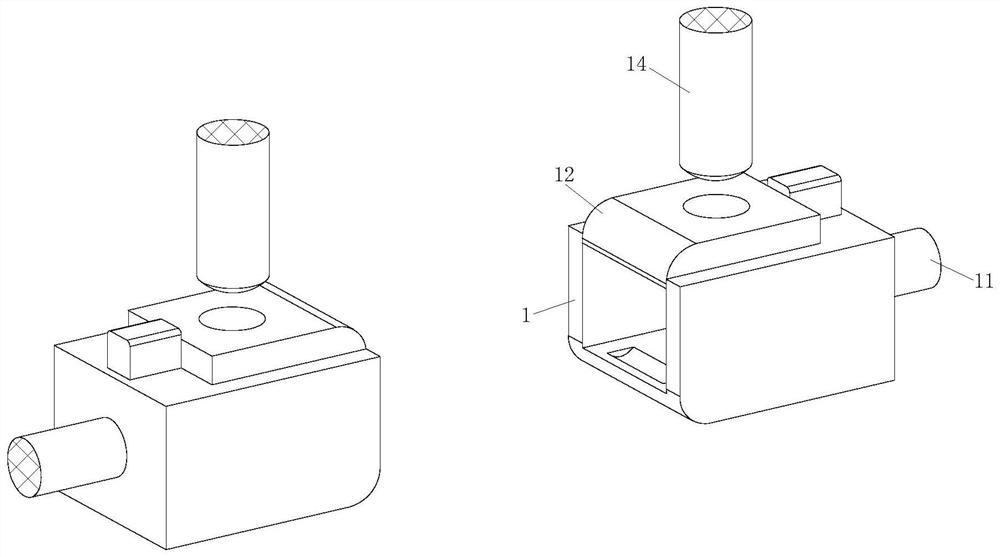

[0034] like Figure 1 to Figure 6 As shown in the embodiment of the present invention, a method for detecting the quality of finished products used in the production of masks, the steps of the detection method are as follows;

[0035] S1: First, the operators wear clean clothes and sterile gloves to place the produced masks on the operating table and place them flat, and take out the disinfection watering can to sterilize the masks placed for testing;

[0036] S2: Next, check the lines of the finished product quality testing equipment, connect the lines safely and energize, take a set of sterilized masks and place them on the finished product quality testing equipment for testing, and observe the operating status of the equipment;

[0037]S3: The equipment is in normal operation, and the sterilized masks on the operating table are placed on the finished product quality testing equipment for testing in turn, the detected defective parts are thrown into the waste recycling box f...

Embodiment 2

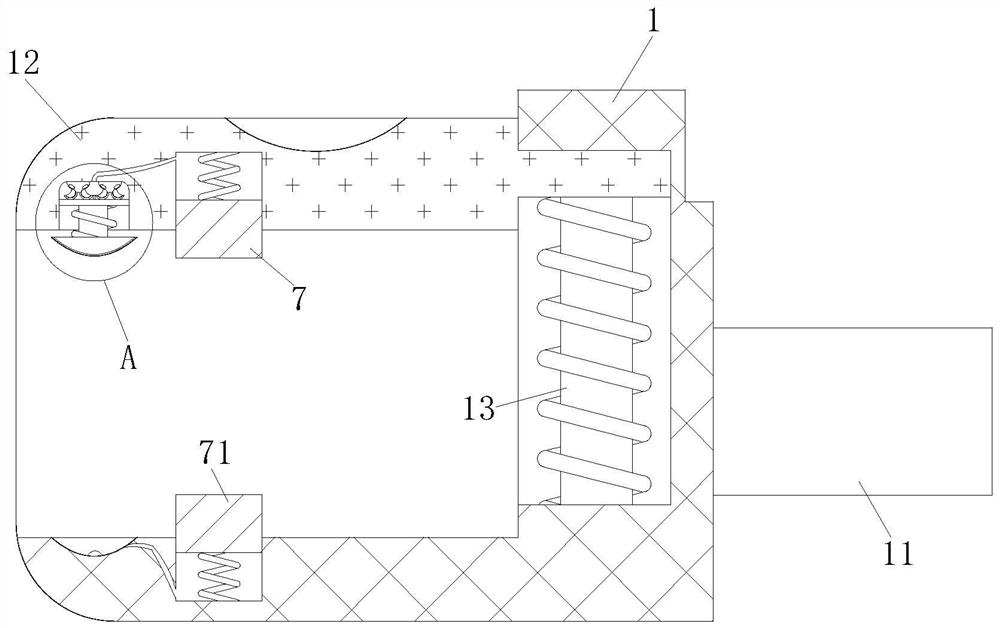

[0048] like Figure 7 As shown in the comparison example 1, another embodiment of the present invention is: the convex block 51 is provided with a cavity inside; the convex block 51 is provided with a shaking ball 9 inside, and the shaking ball 9 It is located in the cavity of the convex block 51; the collision ball 81 is blown against the shrapnel 82 by the gas, the vibration of the pressing plate 31 drives the convex block 51 to vibrate, and the shaking ball 9 inside the convex block 51 is vibrated in the cavity, thereby The shaking collides with the inner wall of the convex block 51 , which has the effect of assisting the vibration of the convex block 51 , preventing the fluff from adhering to the side wall of the convex block 51 , and facilitating the cleaning of the fluff.

[0049]Working principle, to test the quality of the mask, place the two sides of the mask on the inner side walls of the two sets of placement plates 1, and the output end of the electric push cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com