Carbon plate for running shoes and preparation method thereof

A carbon plate and running shoe technology, applied in the field of shoe accessories, can solve problems such as low elongation, resistance to shearing and bending, affecting propulsion performance and user experience, and achieve the effect of both support and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solutions of the present invention, detailed descriptions are given below with reference to the embodiments.

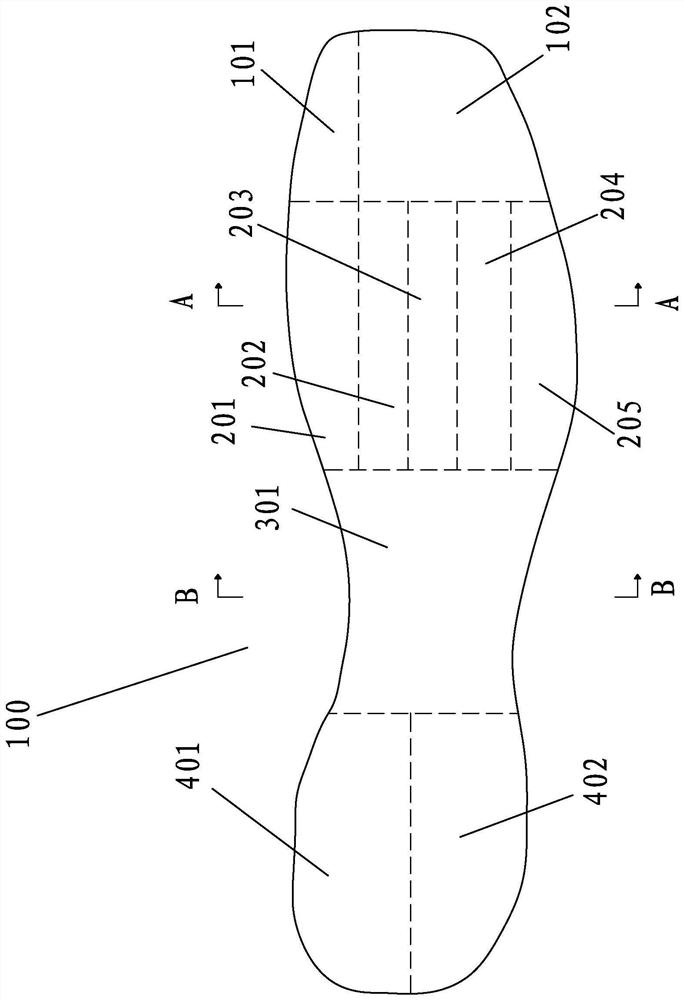

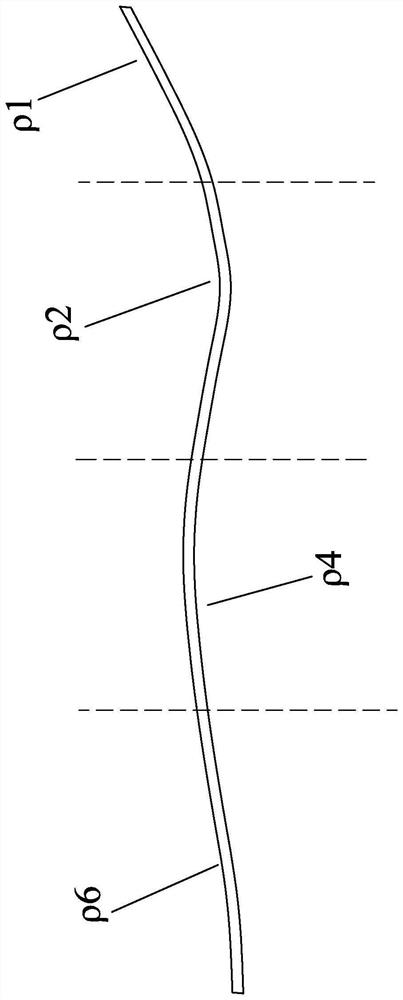

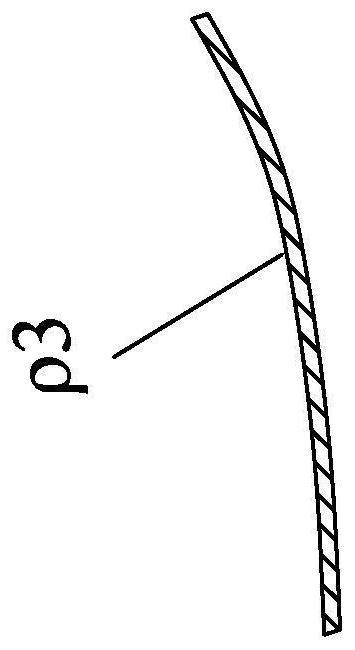

[0039] refer to Figure 1 to Figure 12 , a carbon plate for running shoes, comprising a carbon plate body 100, the area of the carbon plate body 100 corresponding to each metatarsal is set as the metatarsal area, and the metatarsal area (that is, the II area) is sequentially set as the first metatarsal area 201, the second metatarsal area 202 , the third metatarsal region 203, the fourth metatarsal region 204 and the fifth metatarsal region 205, the elastic moduli of the first metatarsal region 201, the second metatarsal region 202, the fourth metatarsal region 204 and the fifth metatarsal region 205 are all smaller than the third metatarsal region 205. Elastic modulus of the metatarsal region 203 . The carbon plate of the present invention is used in running shoes, and the carbon plate can be arranged between two mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com