Brushless DC motor with permanent-magnet disk and no iron core

A motor, ironless technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problem of low utilization rate of magnets, achieve the effect of improving efficiency and operation reliability, small armature inductance, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

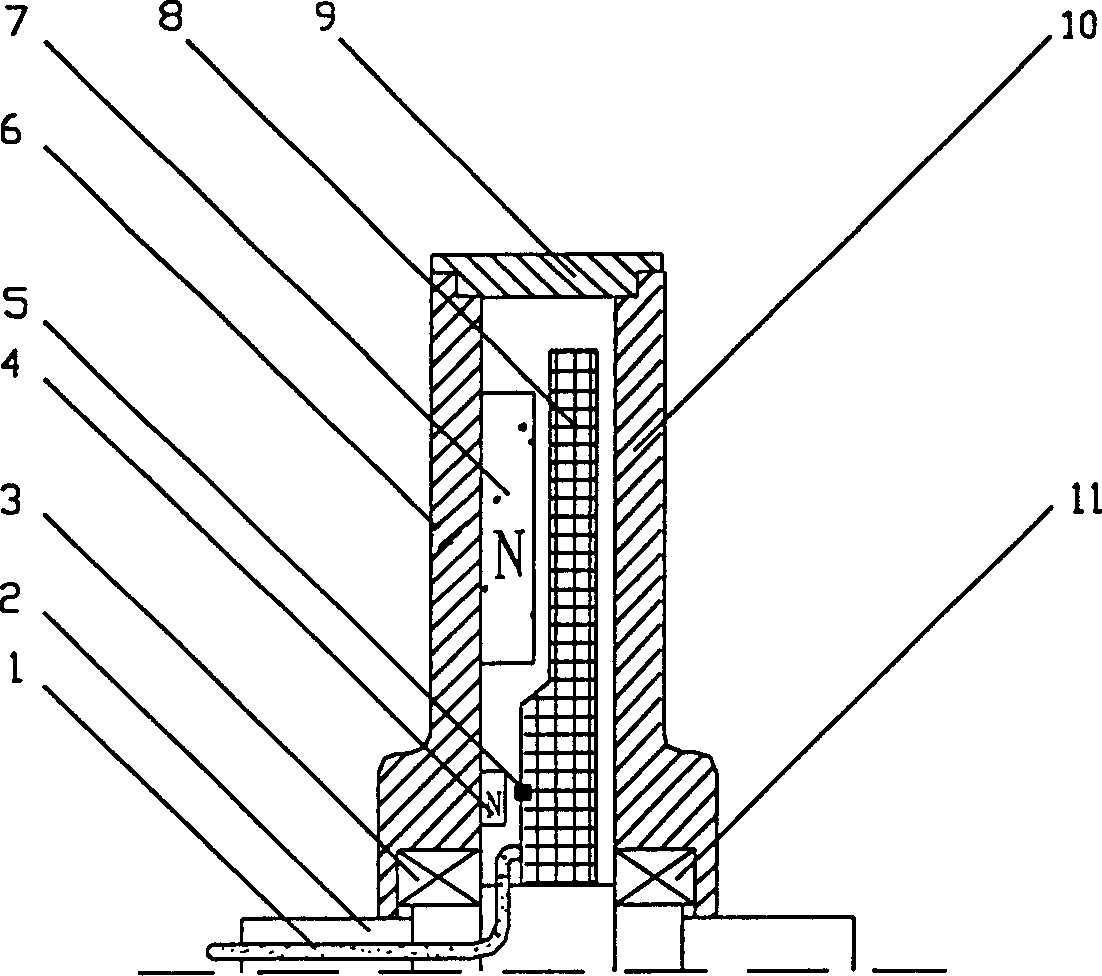

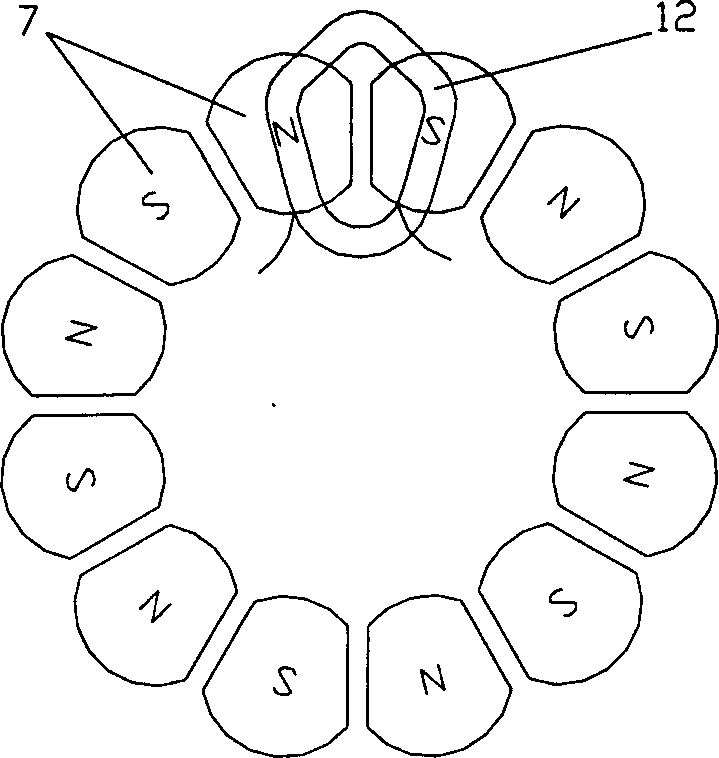

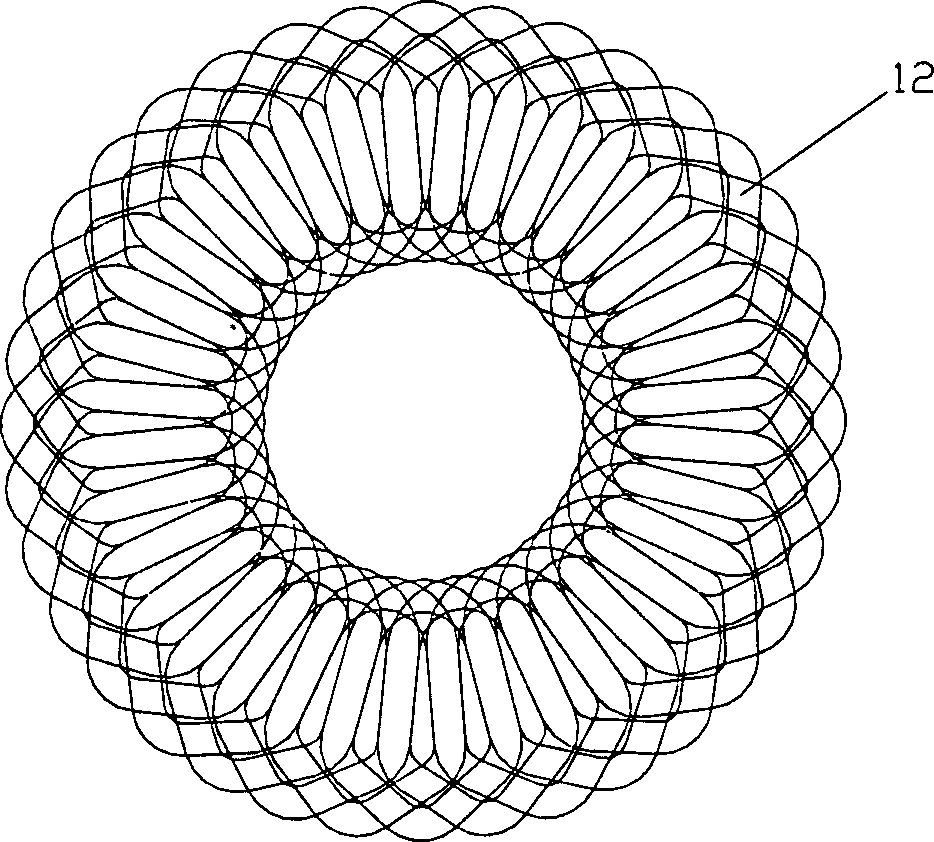

[0015] like figure 1 As shown, the present invention includes shaft 2, bearings 3, 11, analog magnetic pole 4, position sensor 5, permanent magnet 7, armature disc 8, and housing 6; housing 6 includes end cover 10 and side wall 9. The bearings 3 and 11 are set on the shaft 2, the permanent magnet 7 is bonded to the end cover 10, the end cover 10 is connected with the bearings 3 and 11, and forms the motor rotor together with the permanent magnet 7; the armature disc 8 is fixed to the shaft 2 Connected, as the motor stator; the position sensor 5 is located at an appropriate position on the armature disk, that is, the position towards the axis, and its basic principle is not located under the main magnetic pole, so the thickness of the air gap can be reduced. The lead wire 1, the winding tap and the sensor lead wire are drawn out from the hollow part of the shaft 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com