Industrial accessory grooving equipment

A slotting equipment, industrial technology, applied in the direction of metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of low accuracy of parts, low quality of work, slow work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

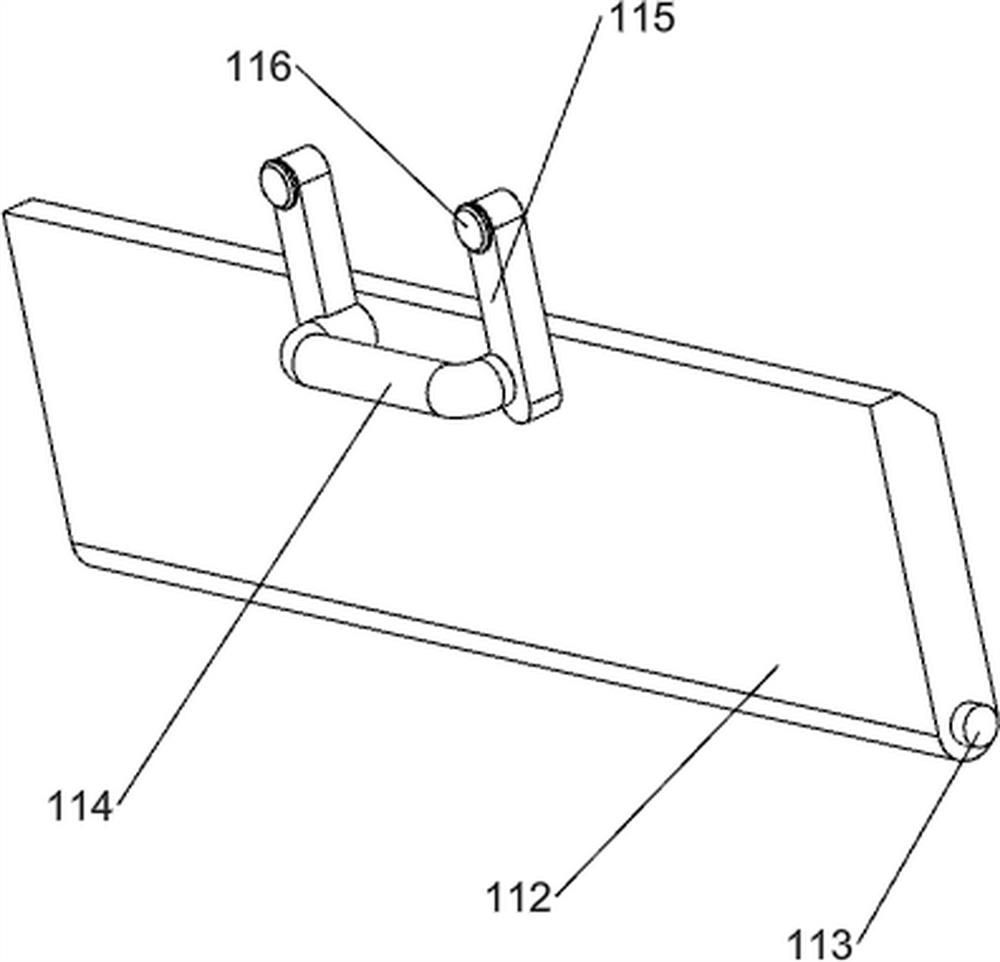

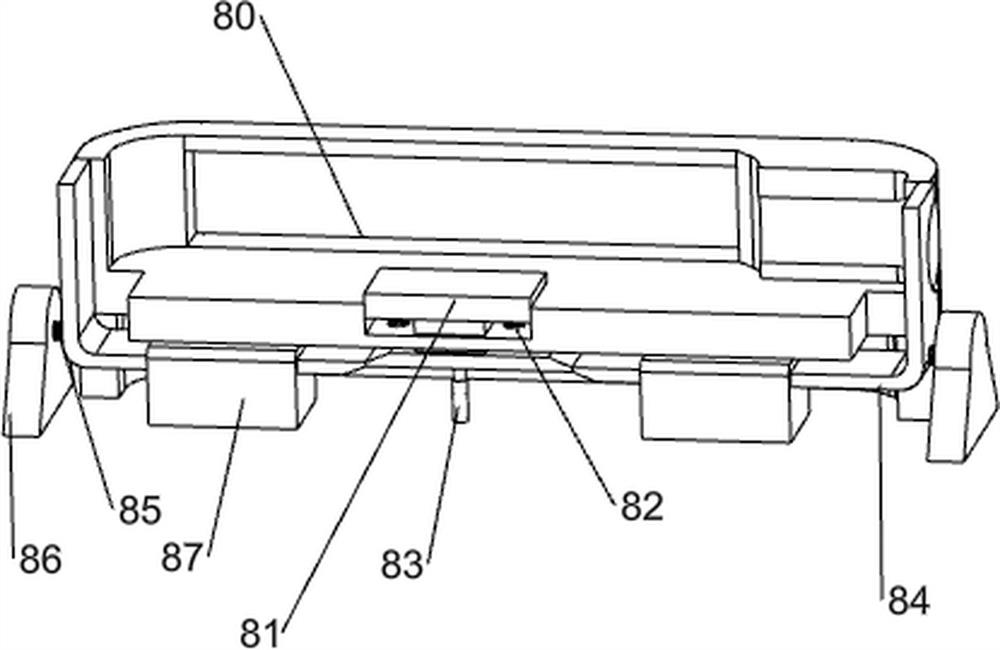

[0031] A slotting equipment for industrial accessories, such as Figure 1-7 As shown, it includes a first support seat 1, a motor 2, an electric rotation 3, a limit ring 4, a support rod 5, a transmission mechanism 6, a feeding mechanism 7 and a clamping mechanism 8. The upper right side of the first support seat 1 is provided with Transmission mechanism 6, the left side of the transmission mechanism 6 is provided with a limit ring 4, the left side of the limit ring 4 is connected with a support rod 5, the left side of the support rod 5 is provided with a motor 2, the output shaft of the motor 2 is connected with an electric rotary 3, and the ground is provided with The feeding mechanism 7 and the upper left side of the first support base 1 are connected with a clamping mechanism 8 .

[0032] When it is necessary to use the slotting equipment for industrial parts, people put the parts into the feeding mechanism 7, and the feeding mechanism 7 rotates to drive the parts to be in...

Embodiment 2

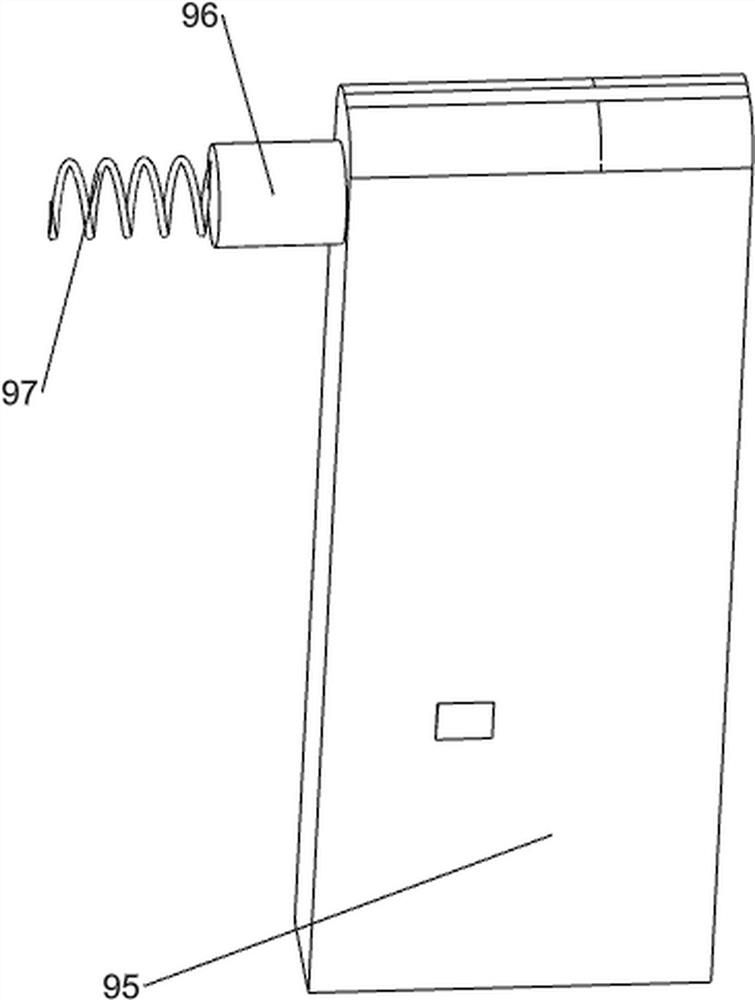

[0040] On the basis of Example 1, as figure 1 , Figure 8-Figure 12 As shown, it also includes a cover opening mechanism 9, and the cover opening mechanism 9 includes a fifth support seat 90, a fourth transmission shaft 91, a second pulley 92, a second flat belt 93, a missing gear 94, a sixth support seat 95, The first limit rod 96, the third return spring 97 and the transmission plate 98, the top of the first support base 1 is connected with a fifth support base 90, and the fifth support base 90 is rotatably connected with a fourth transmission shaft 91, and the fourth transmission The shaft 91 and the lower part of the first transmission shaft 64 are connected with a second pulley 92, a second flat belt 93 is wound between the second pulley 92, a missing gear 94 is connected to the top of the fourth transmission shaft 91, and the top of the first support seat 1 A sixth support seat 95 is connected to the rear side, and a first limit rod 96 is connected to the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com