A kind of porous sintered brick automatic billet separating machine and its billet separating method

An automatic billet separating machine and sintered brick technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, high operating costs, long production lines, etc., to improve work efficiency, reduce production costs, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

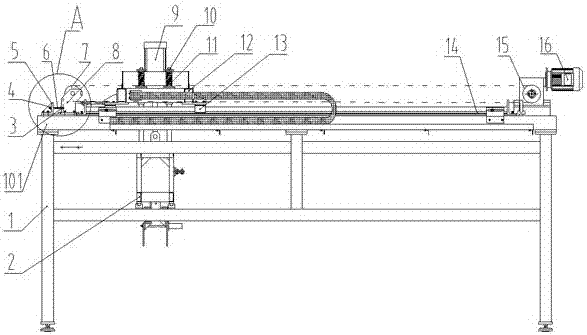

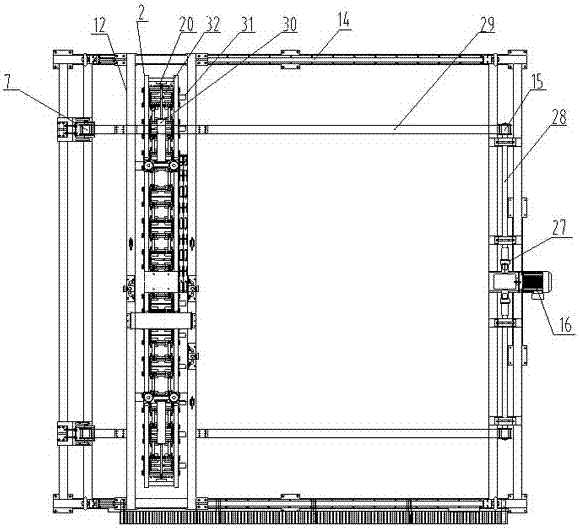

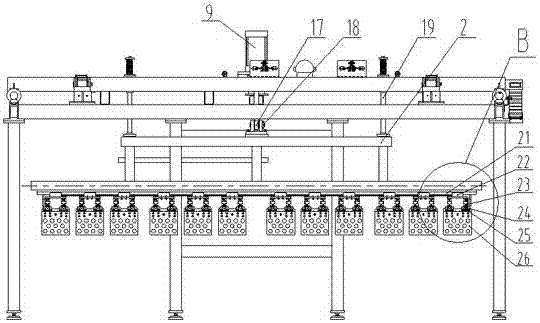

[0025] As shown in the figure, a sintered brick automatic blanking machine includes a frame 1, and the frame 1 includes a frame beam 101, and two guide rails I14 are arranged at intervals in parallel on the frame beam 101, On the two guide rails I14, a moving frame 12 is straddled by the slider I13, and the moving frame 12 is driven by the moving frame driving device to move along the two guide rails I14.

[0026] Described moving frame driving device comprises the motor speed reducer 16 with double output shaft that is located at one end of the frame, and the two transmission shafts 28 that are connected with the two output shafts of the motor speed reducer 16 through a coupling 27 respectively and Be located at two drive pulleys 15 on two power transmission shafts 28, be provided with two driven pulleys 7 correspondingly with two dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com