New energy automobile exhaust pipe inner wall burr cleaning device

A new energy vehicle and cleaning device technology, applied in the field of new energy vehicle exhaust pipe inner wall burr cleaning device, can solve the problems of low work efficiency and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

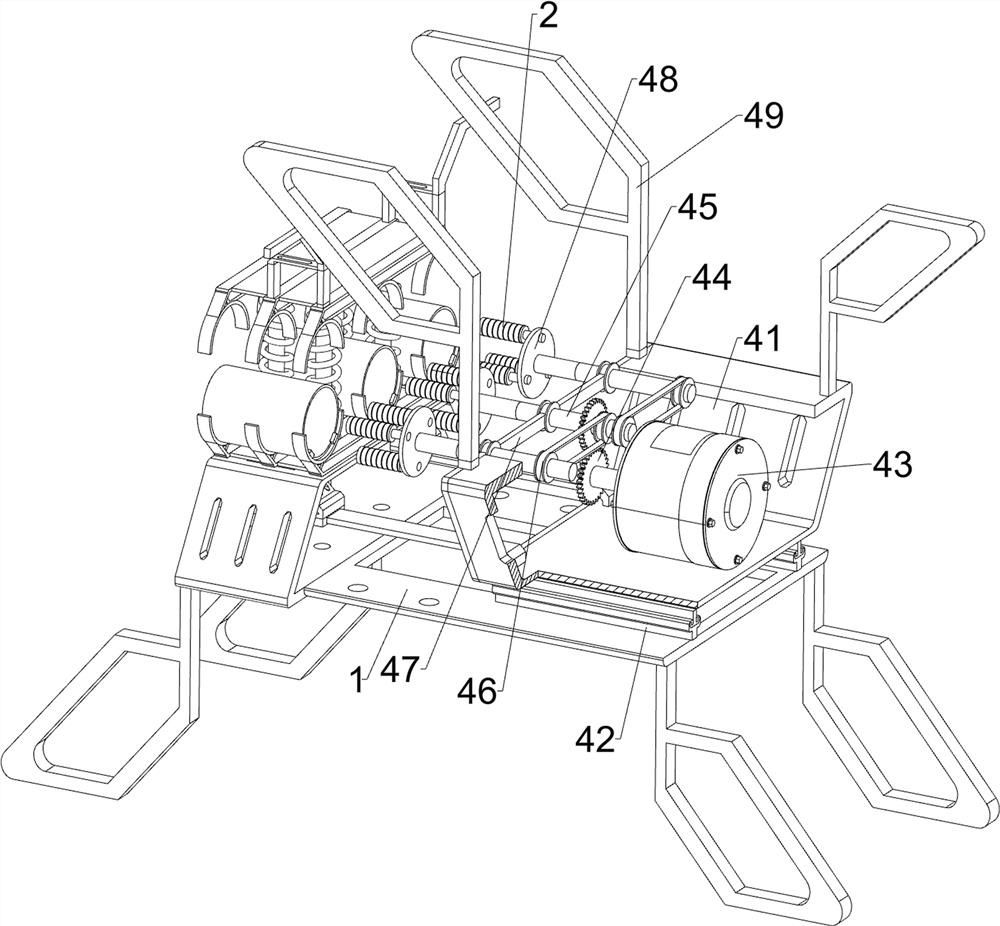

[0033] A burr cleaning device for the inner wall of an exhaust pipe of a new energy vehicle, comprising a support frame 1, a grinding roller 2, a mounting frame 3, a drive mechanism 4 and a limit mechanism 5, please refer to Figure 1-Figure 6 As shown in the figure, the mounting bracket 3 is installed on the left side of the outer top of the support frame 1 by welding, and the positioning blocks are fixed on the right part of the upper three sides of the upper part of the mounting frame 3. The operator can place the exhaust pipe on the mounting frame 3 , a drive mechanism 4 is installed on the support frame 1, the drive mechanism 4 is used to provide power, and three groups of grinding rollers 2 are installed on the driving mechanism 4, and the number of each group of grinding rollers 2 is three. When the grinding rollers 2 rotate, the grinding rollers 2. The burrs on the inner wall of the exhaust pipe can be removed. A limit mechanism 5 is installed on the left of the support...

Embodiment 2

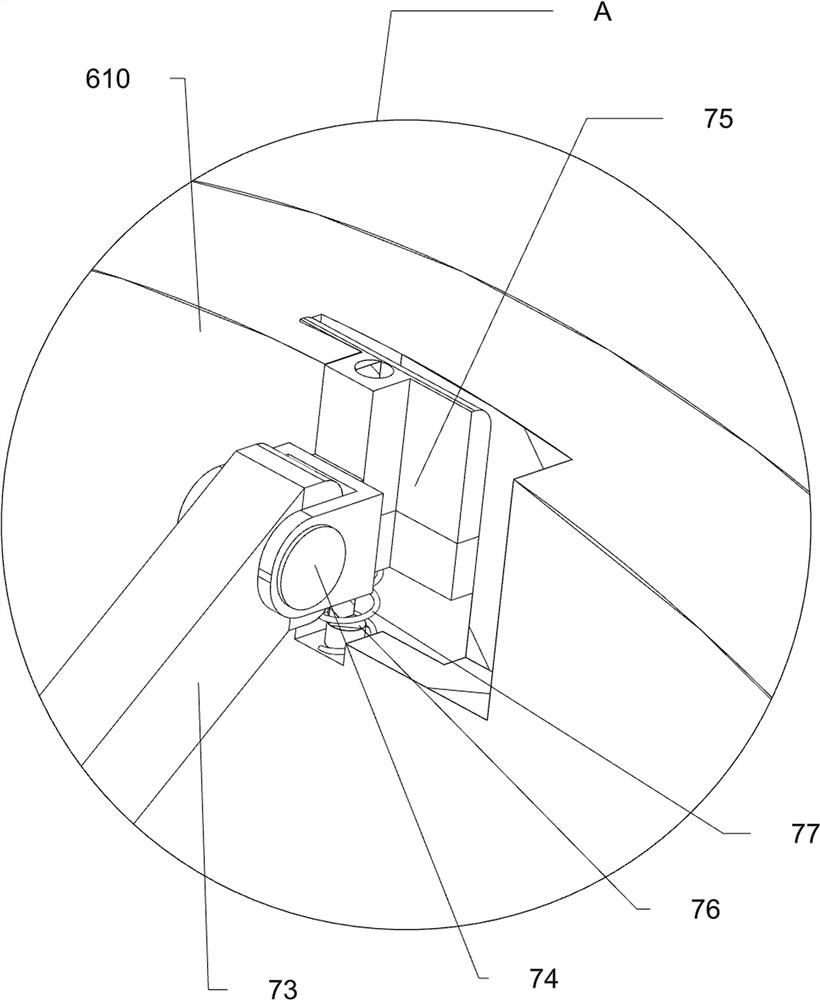

[0040] On the basis of Embodiment 1, a cleaning mechanism 6 is also included. The cleaning mechanism 6 includes a fixing rod 61 , a magnet block 62 , a fixing frame 63 , a rotating shaft 64 , a scroll spring 65 , a limiting cylinder 66 , and a guide post 67 , second spring 68, magnet 69 and cleaning disc 610, see figure 1 and Figure 7 As shown, three fixing frames 63 are installed on the upper part of the left side of the support frame 1 evenly spaced by welding, and a rotating shaft 64 is rotatably connected between the upper parts of the three fixing frames 63. The front and rear sides of the rotating shaft 64 are respectively A scroll spring 65 is connected with the upper part of the outer side of the fixing frame 63 on the front and rear sides. The fixed sleeve on the rotating shaft 64 is evenly spaced with three limiting cylinders 66. There is a guide post 67, a second spring 68 is wound between the left end of the guide post 67 and the outer left side of the limiting c...

Embodiment 3

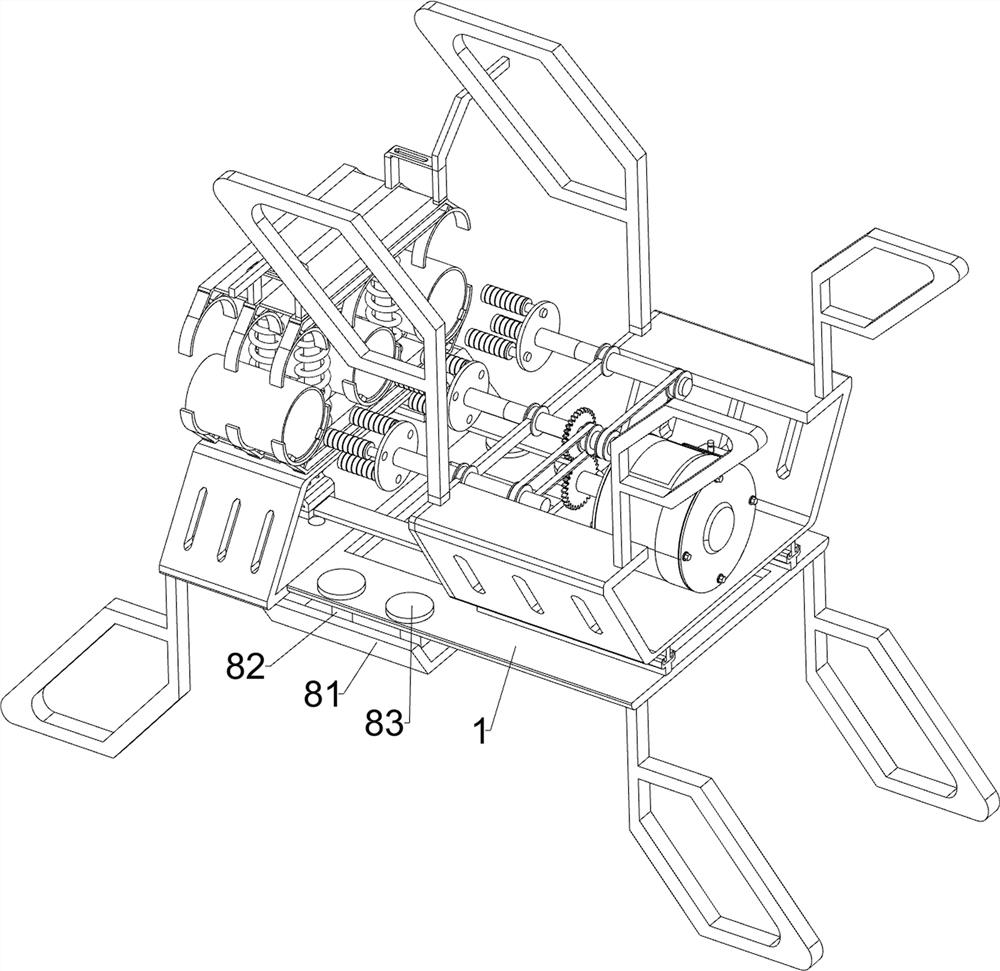

[0045] On the basis of Embodiment 1 and Embodiment 2, a collection mechanism 8 is also included. The collection mechanism 8 includes a collection frame 81, a mounting rod 82 and a fixed threaded disk 83. Please refer to figure 1 and Figure 10 As shown in the figure, two mounting rods 82 are slidably connected with two mounting rods 82 on the bottom left side of the bottom of the support frame 1. The top of the mounting rods 82 is connected with a fixed threaded disk 83 through a threaded rotating type, and the bottom ends of the four mounting rods 82 pass through A collection frame 81 is installed in a welded connection. When the chips are pushed out, the collection frame 81 can collect the chips.

[0046] Also includes a material guide mechanism 9, the material guide mechanism 9 includes a fixed column 91 and a guide plate 92, please refer to figure 1 and Figure 11 As shown, the bottom left side of the bottom of the fixing frame 63 is symmetrically fixed with a fixed colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com