Hot rolling device and hot rolling process for producing filter cloth

A filter cloth and hot roll technology, which is applied in household refrigeration equipment, cooling fluid circulation equipment, transportation and packaging, etc., can solve the problems of sales or transportation impact, cost loss, uneven quality of finished products, etc., and reduce the possibility of overheating Sex, ensure accuracy, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

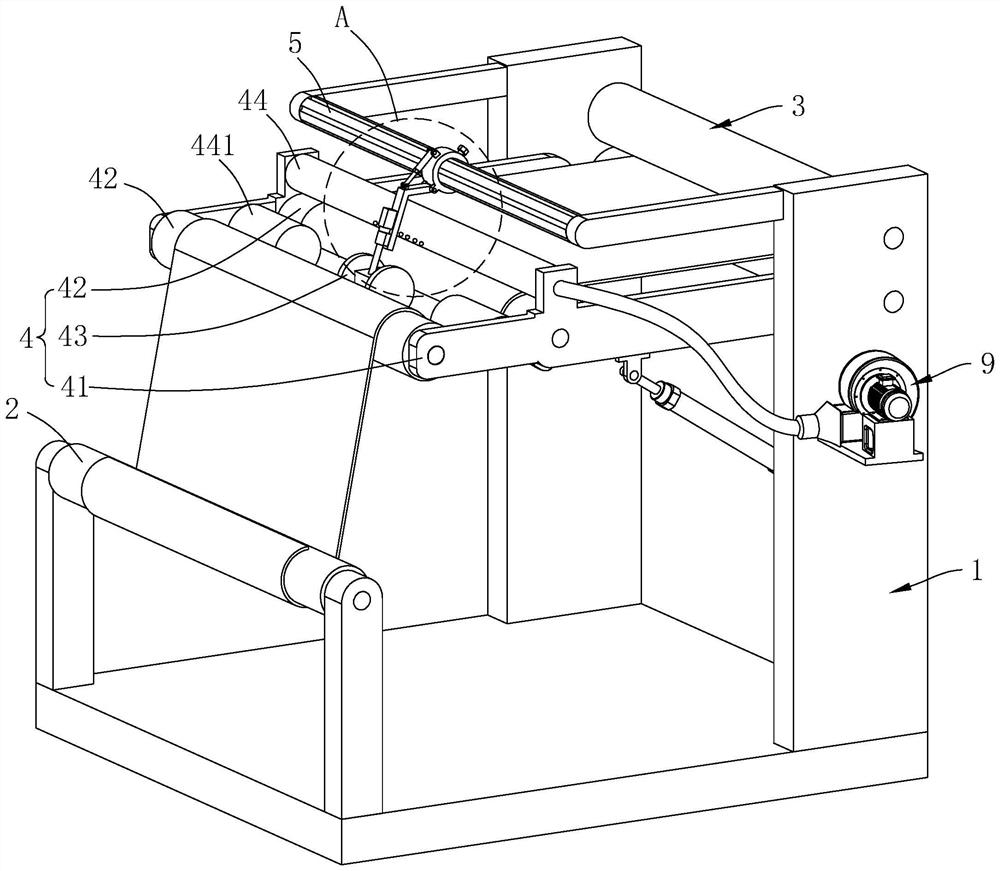

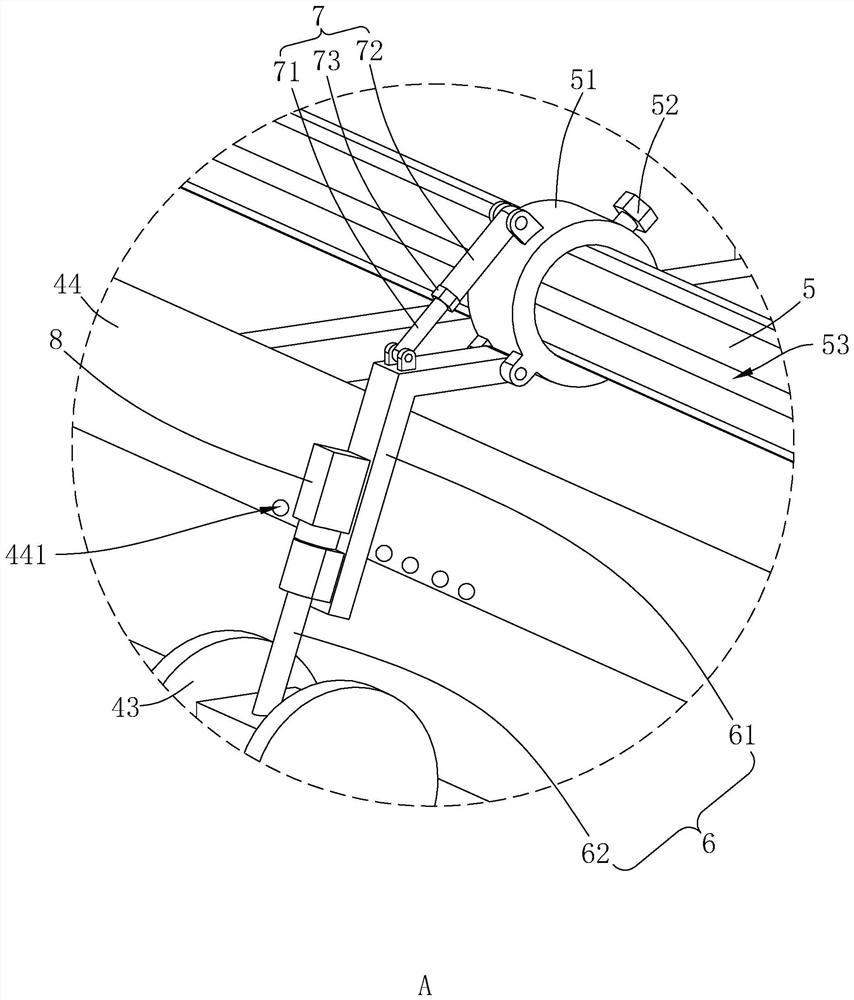

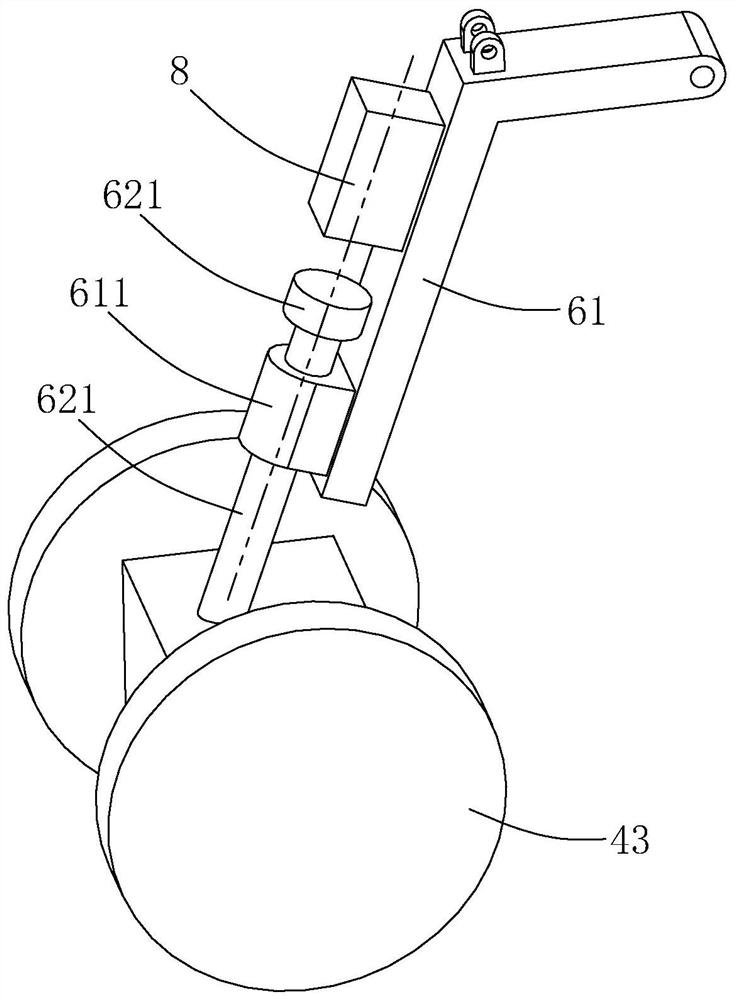

[0036] Attached to the following Figure 1-3 This application will be described in further detail.

[0037] The embodiment of the present application discloses a hot rolling device for producing filter cloth. refer to figure 1 , a hot rolling device for producing filter cloth includes a frame 1 , a winding drum 2 and a pair of hot rolling rolls 3 . The hot rolling rolls 3 are rotatably connected to the frame 1 , and the rotation axes of the two hot rolling rolls 3 are parallel, and the two are arranged in a gap. The reel 2 is rotatably connected to the frame 1, and the two are detachably connected. When in use, the filter cloth output from the hot roll 3 can be wound on the reel 2, so that the filter cloth can be collected and packaged.

[0038] refer to figure 1 , the frame 1 is provided with a measuring assembly 4 , and the measuring assembly 4 includes a support frame 41 , a support roller 42 and a measuring roller 43 . In this embodiment, the support frame 41 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com