Extruding and pulling process for low conductor core of carbon fiber composite material

A composite material and carbon fiber technology, which is applied in the field of low wire core extrusion and pulling technology of carbon fiber composite materials, can solve problems such as poor process effect, and achieve the effects of good molding effect, complete performance and improved toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

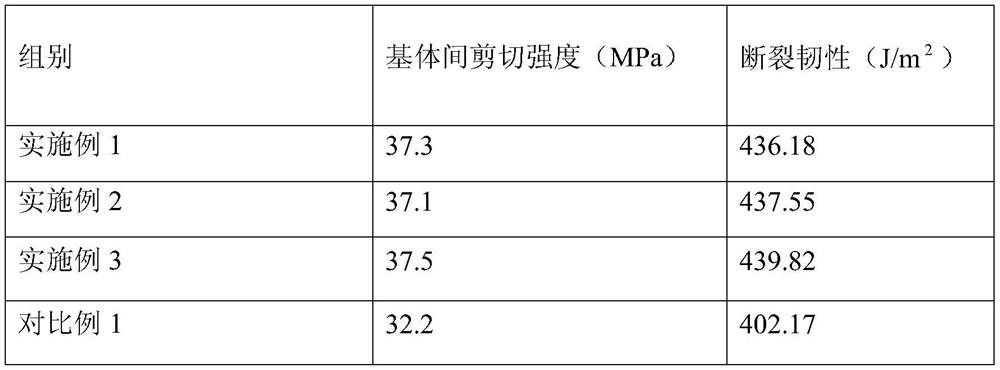

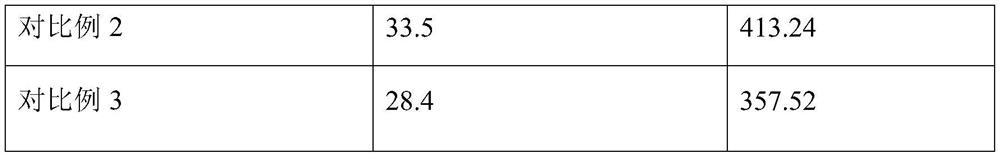

Examples

Embodiment 1

[0024] A carbon fiber composite material low wire core extrusion process of this embodiment comprises the following steps:

[0025] Step 1: Boil and clean the carbon fiber twice with acetone solution at 100°C, then carry out graft modification treatment, and then mix with epoxy resin at a weight ratio of 3:2, and the mixing speed is 200r / min. later use 60 Co-r rays were irradiated for 20s, and the irradiation was completed to obtain the matrix;

[0026] Step 2, firstly mix the matrix and processing aids according to the weight ratio of 1:2, the mixing speed is 100r / min, and the mixing time is 30min, and then sent to the drawing machine for extrusion, the outlet temperature is 120°C, and the extrusion speed is Be 220mm / min, obtain the base wire core;

[0027] Step 3: Thermally treat the base wire core first, and then place it in a quality upgrading solution for water bath treatment. The water bath conditions are -5°C for 20 minutes, and 10°C for 10 minutes;

[0028] Step 4: ...

Embodiment 2

[0037] A carbon fiber composite material low wire core extrusion process of this embodiment comprises the following steps:

[0038] Step 1: Boil the carbon fiber with acetone solution for 3 times, the boiling temperature is 100°C, then carry out graft modification treatment, and then mix with epoxy resin according to the weight ratio of 3:2, the mixing speed is 300r / min, later use 60 Co-r rays are irradiated for 20-30s, and the irradiation is completed to obtain the matrix;

[0039] Step 2: Mix the matrix and the processing aid at a weight ratio of 1:2, the mixing speed is 200r / min, and the mixing time is 40min, and then sent to the drawing machine for extrusion, the outlet temperature is 130°C, and the extrusion speed is 280mm / min, to obtain the substrate wire core;

[0040] Step 3: Thermally treat the base wire core first, and then place it in a quality upgrading solution for water bath treatment. The water bath conditions are -5°C for 20 minutes, and 10°C for 10 minutes;

...

Embodiment 3

[0050] A carbon fiber composite material low wire core extrusion process of this embodiment comprises the following steps:

[0051] Step 1: Boil and clean the carbon fiber for 3 times with acetone solution at 100°C, then carry out graft modification treatment, and then mix with epoxy resin at a weight ratio of 3:2, and the mixing speed is 250r / min. later use 60 Co-r rays were irradiated for 25s, and the irradiation was completed to obtain the matrix;

[0052] Step 2, firstly mix the matrix and processing aids according to the weight ratio of 1:2, the mixing speed is 150r / min, and the mixing time is 35min, and then sent to the drawing machine for extrusion, the outlet temperature is 125°C, and the extrusion speed is Be 50mm / min, obtain the base wire core;

[0053] Step 3: Thermally treat the base wire core first, and then place it in a quality upgrading solution for water bath treatment. The water bath conditions are -5°C for 20 minutes, and 10°C for 10 minutes;

[0054] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com