One-way safety tongs

A safety gear, one-way technology, applied in the field of safety gear, can solve the problems of large installation space, increased size of safety gear, large friction coefficient, etc., and achieve the effect of small structural space and stable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

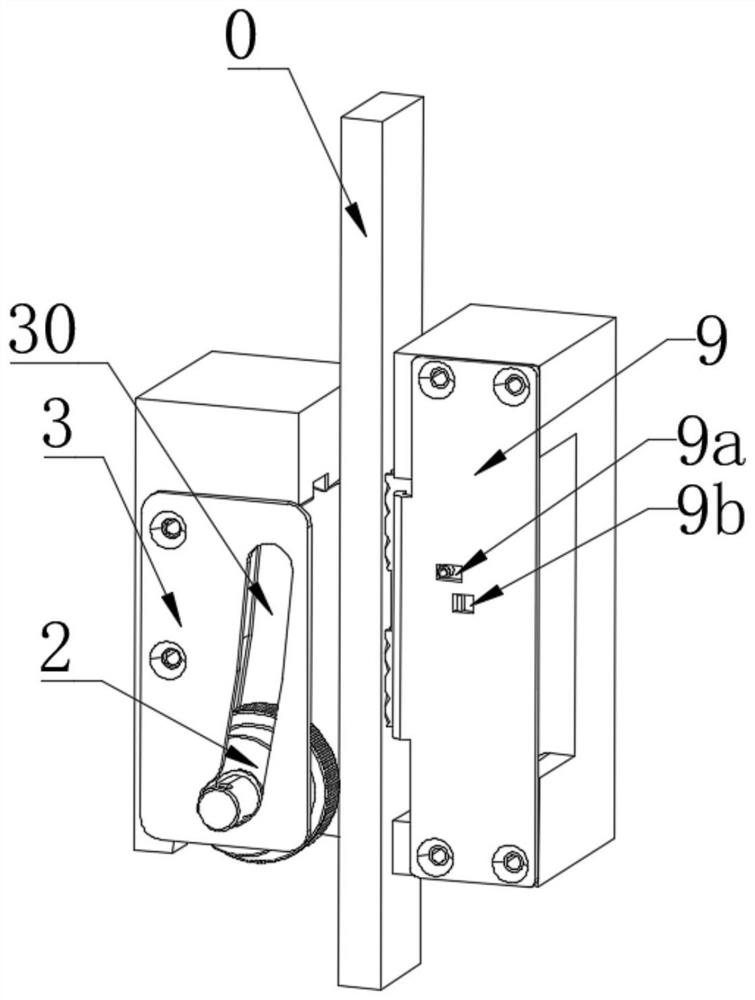

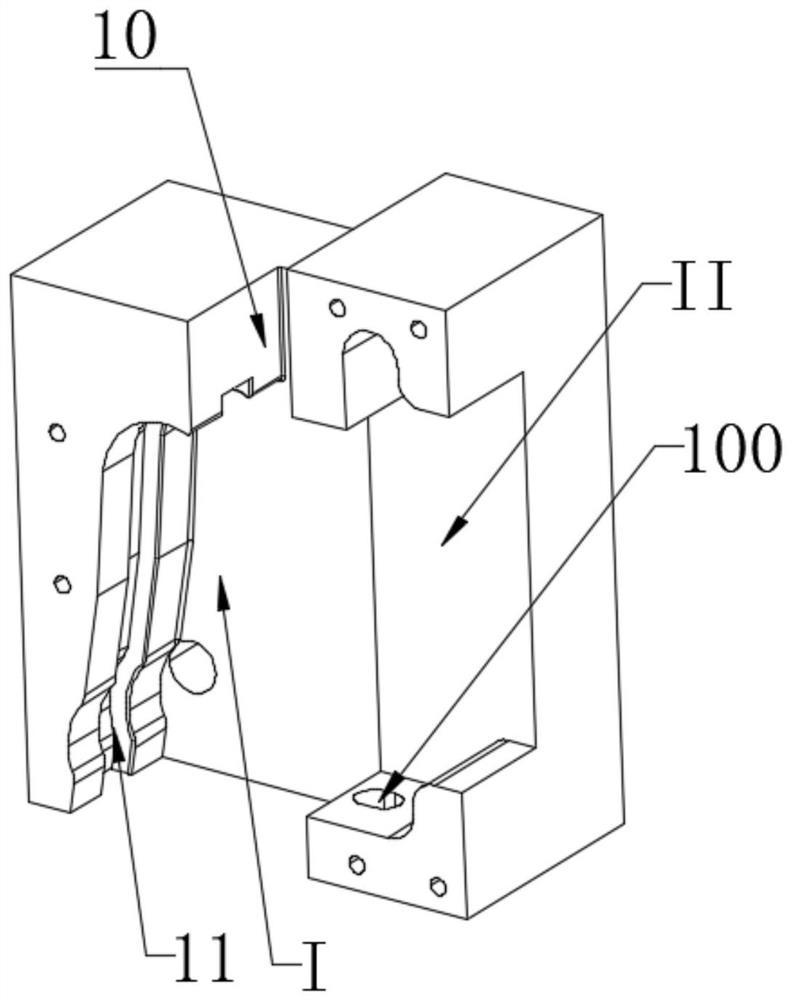

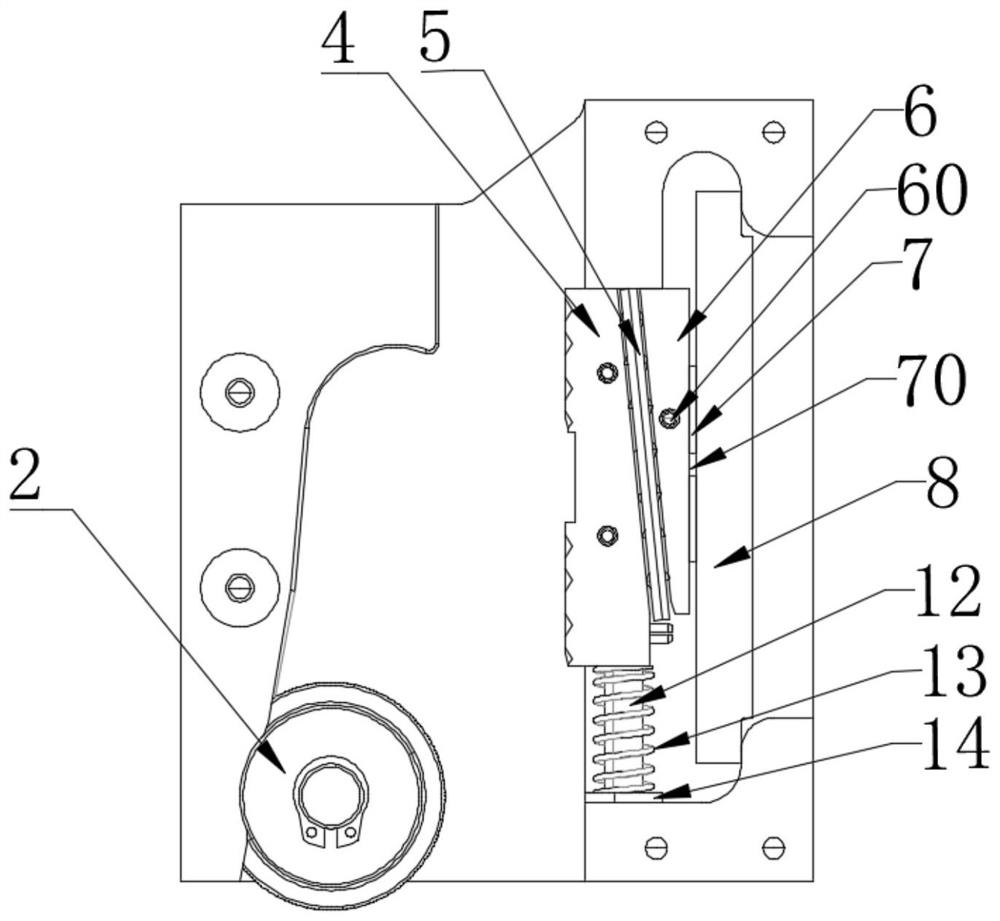

[0025] like Figure 1-4 As shown, the one-way safety gear of this embodiment includes a caliper body 1, a braking roller 2, a guide plate 3, a fixed wedge 4, a ball cage 5, a sliding seat 6, an adjustment pad 7, and a strip spring 8 , cover plate 9.

[0026] Specifically, the caliper body 1 has a vertically extending guide rail channel 10. The caliper body 1 is located on the left and right sides of the guide rail channel 10 to form a first concave portion I and a second concave portion II. The first concave portion I is used for installing the brake roller 2. , the second recess II is used to install the fixed wedge 4, the ball cage 5, the sliding seat 6, the adjusting pad 7, and the strip spring 8, so that the brake roller 2 and the fixed wedge 4 are located on the left side of the guide rail channel 10 respectively. , on the right side, in order to cooperate with the elevator guide rail 0 brake.

[0027] Wherein, the front side of the first concave portion 1 of the calipe...

Embodiment 2

[0035] The difference between the one-way safety gear of this embodiment and Embodiment 1 is:

[0036] The ball cage can also be replaced with a roller cage or a wear-reducing block to reduce the sliding resistance of the fixed wedge; it can meet the needs of different applications;

[0037] For other structures, refer to Embodiment 1.

Embodiment 3

[0039] The difference between the one-way safety gear of this embodiment and Embodiment 1 is:

[0040] According to the actual application requirements, one or more of the sliding seat and the adjustment pad can be omitted; the structure is diversified to meet the needs of different applications;

[0041] For other structures, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com