Safe anti-falling lifting hook for crane

A crane and hook technology, which is applied to the field of safety anti-fall hooks for cranes, can solve the problems such as the inability to guarantee the safety of the crane, and achieve the effects of preventing the hook head from falling, improving the safety guarantee, and reducing the descending speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

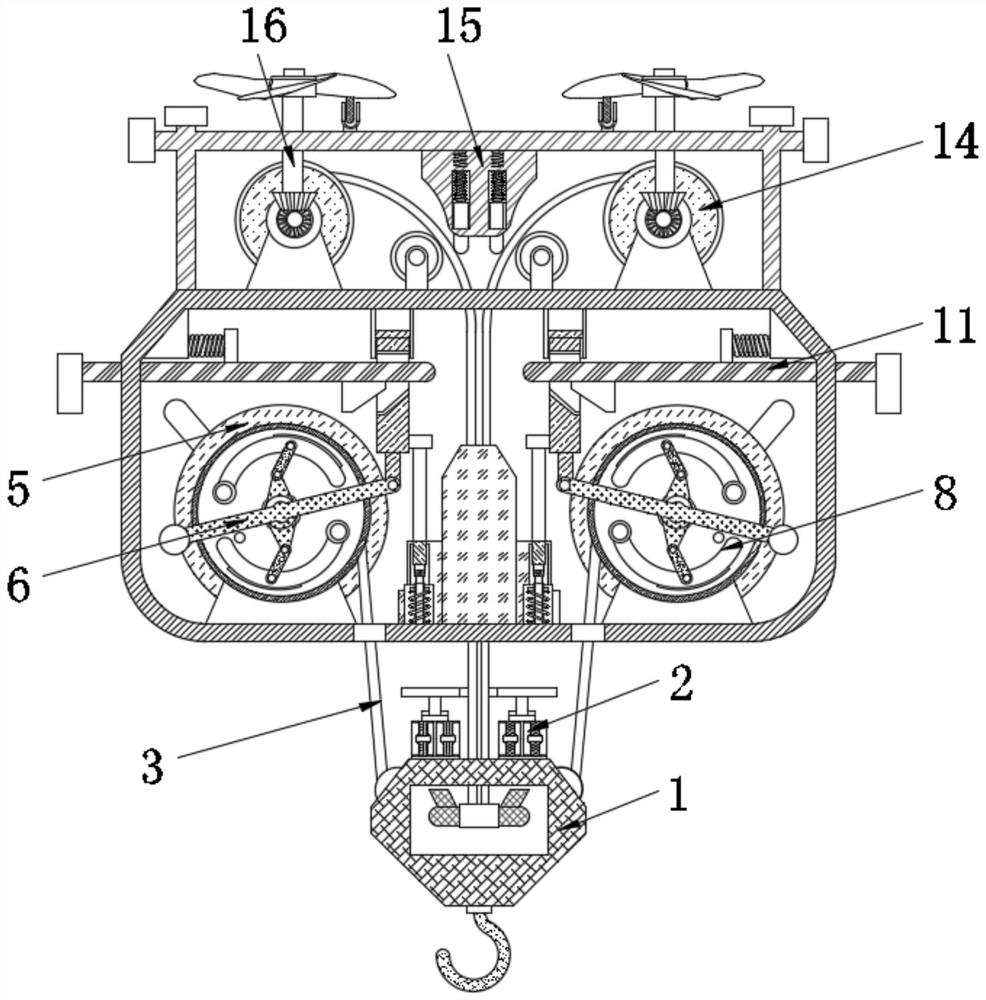

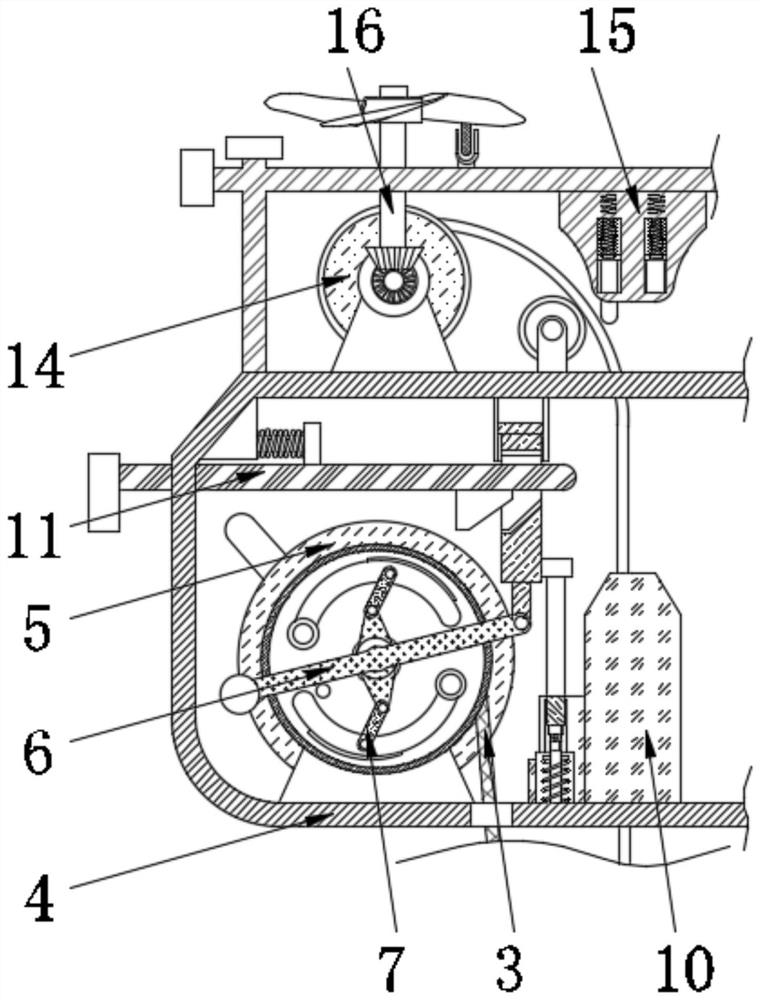

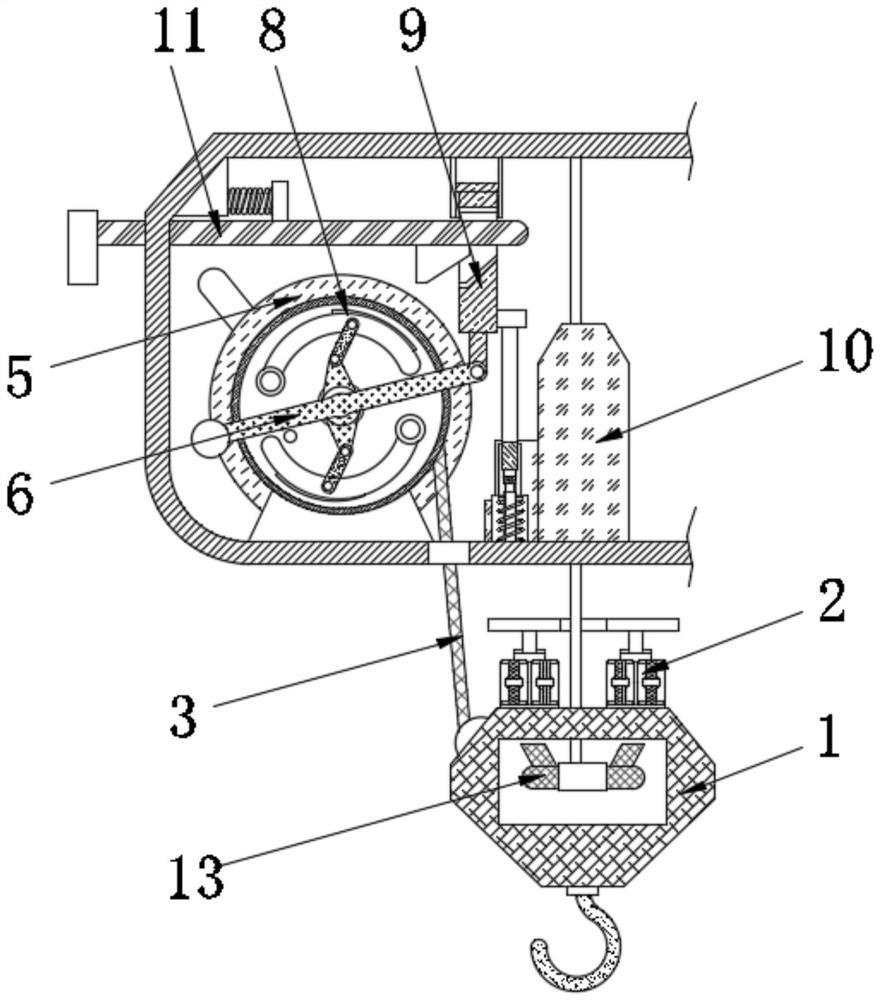

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

[0020] The present invention provides a safety anti-falling hook for a crane, as shown in the attached figure 1 to the attached Figure 4 Shown: including the hook head 1, the upper surface of the hook head 1 is fixedly installed with a buffer seat 2, and the upper left and right sides of the hook head 1 are fixedly connected with a wire rope 3, and the wire rope 3 runs through the bottom of the shell 4, The buffer seat 2 and the shell 4 are arranged correspondingly up and down, the top of the wire rope 3 is movably connected with a guide plate 5, the guide plate 5 is fixedly connected with the drive shaft, and a swing shaft 6 is inserted into the guide plate 5, and the swing shaft The outer end of 6 is provided with a weighting block, the upper and lower ends of the swing shaft 6 are movably connected with a bracket 7, and the end of the bracket 7 is movably installe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap