Fully-fabricated building and assembly method thereof

A fully assembled and architectural technology, which is applied in construction, building structure, and building material processing, to achieve the effects of simple dismantling, simple production and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention is further described below with reference to specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0061] For ease of description, the relative positional relationship of each component, such as top, bottom, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of the present application.

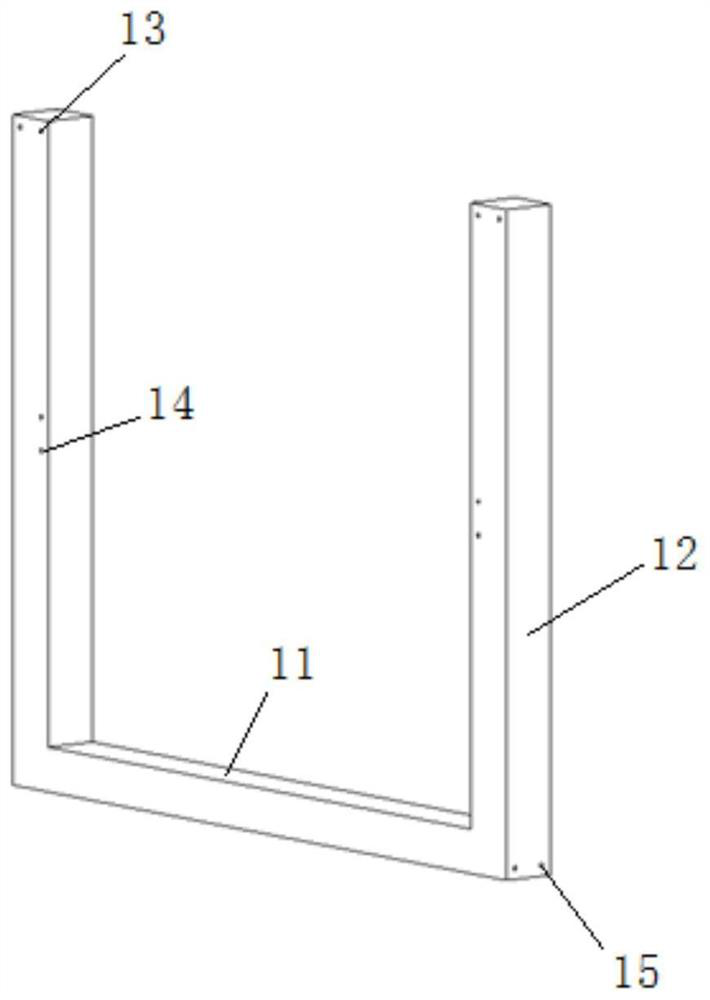

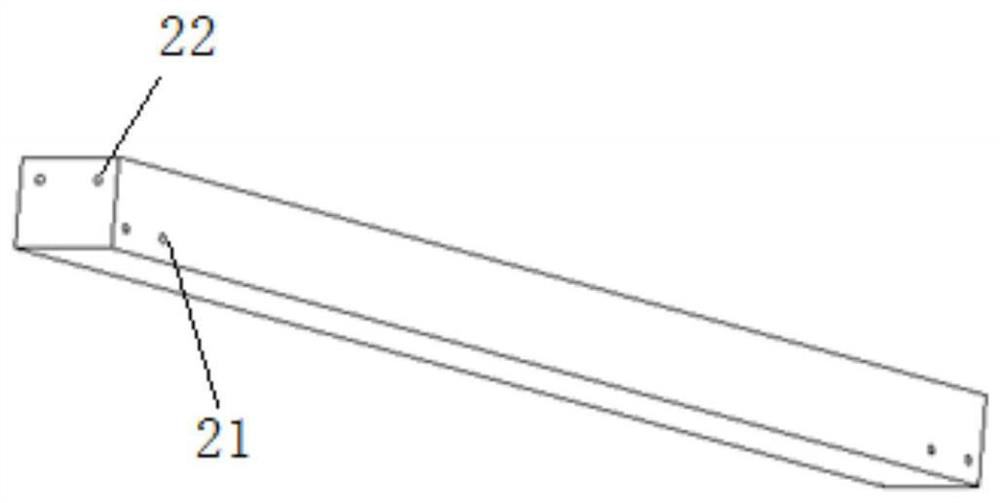

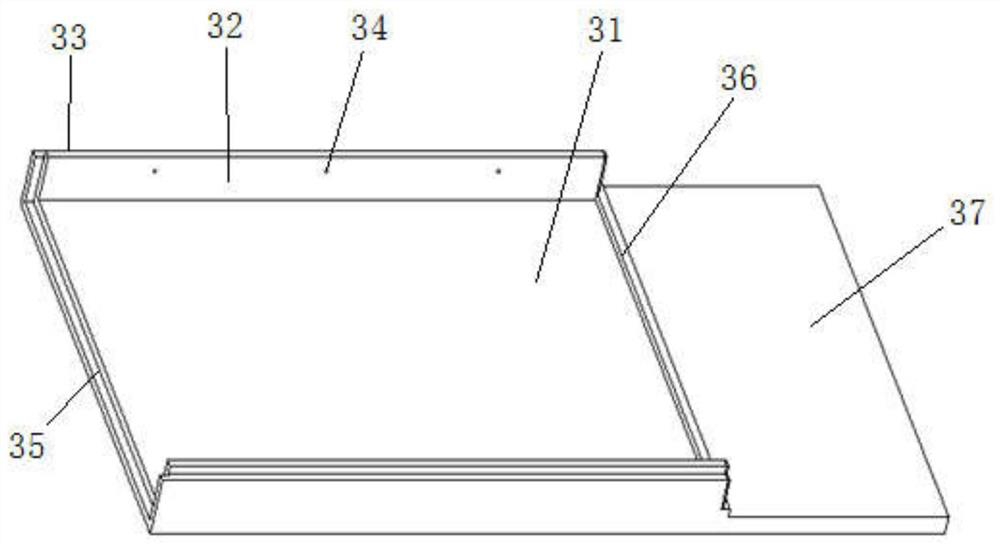

[0062] like figure 1 - Figure 28 As shown, an embodiment of the fully assembled building of the present invention includes a series of prefabricated supports 1 , prefabricated beams 2 , prefabricated bottom plates 3 , prefabricated side plates 4 , prefabricated top plates 5 and prefabricated baffles 6 .

[0063] like figure 1 As shown, the prefabricated support 1 includes a horizontally arranged structural beam 11 and a vertically arranged structural column 12 at both ends of the structural beam 11. The structural beam 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com