Stay Cable Built-in Vibration Damper

A cable-stayed, built-in technology, applied to bridge parts, bridges, buildings, etc., can solve the problem of affecting the performance of high-damping rubber cylinders, the difficulty of installing high-damping rubber cylinders, and the high-damping rubber cylinders Inconsistent thickness and other problems, to achieve good vibration reduction and limit effect, high practical value, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

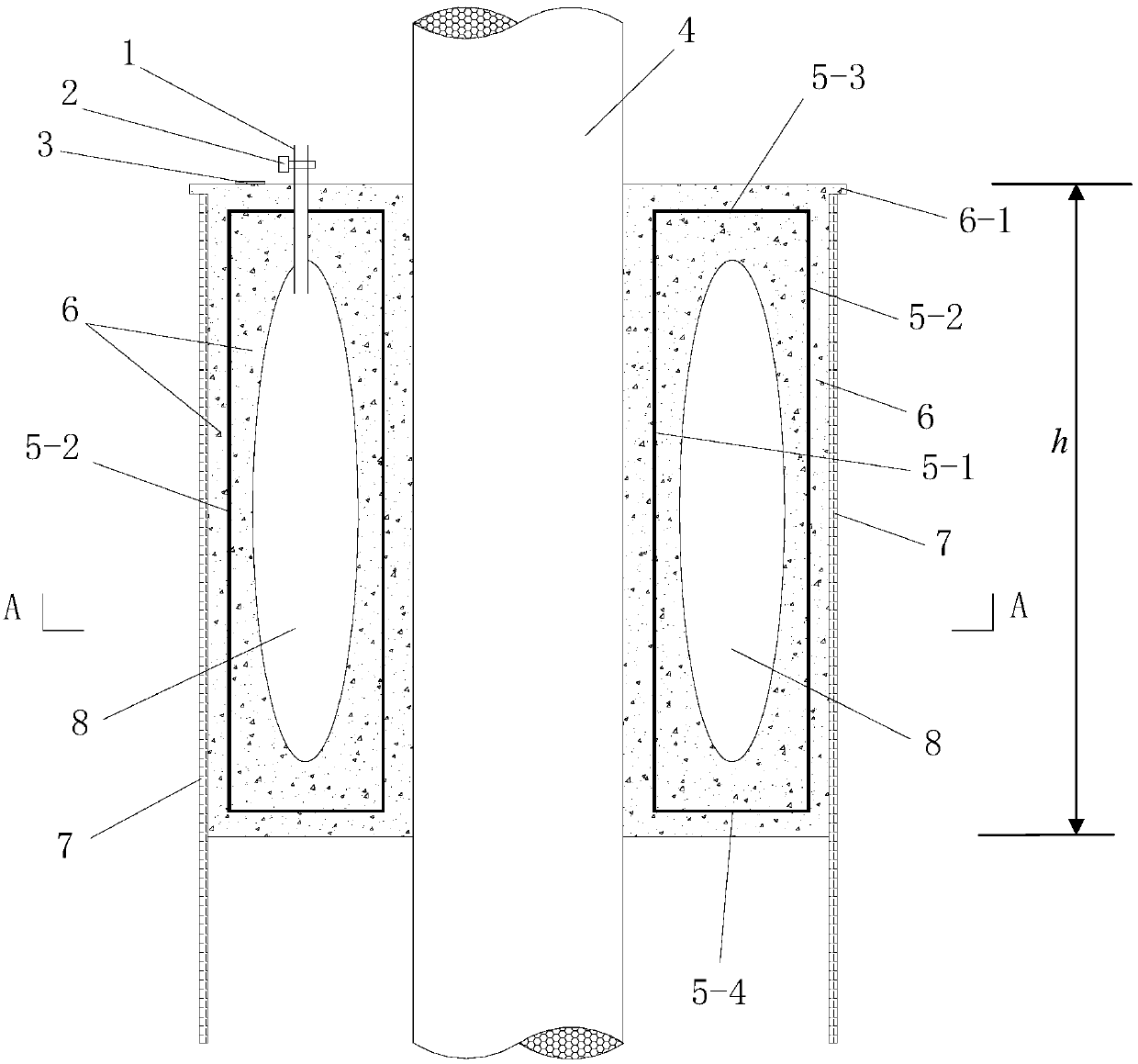

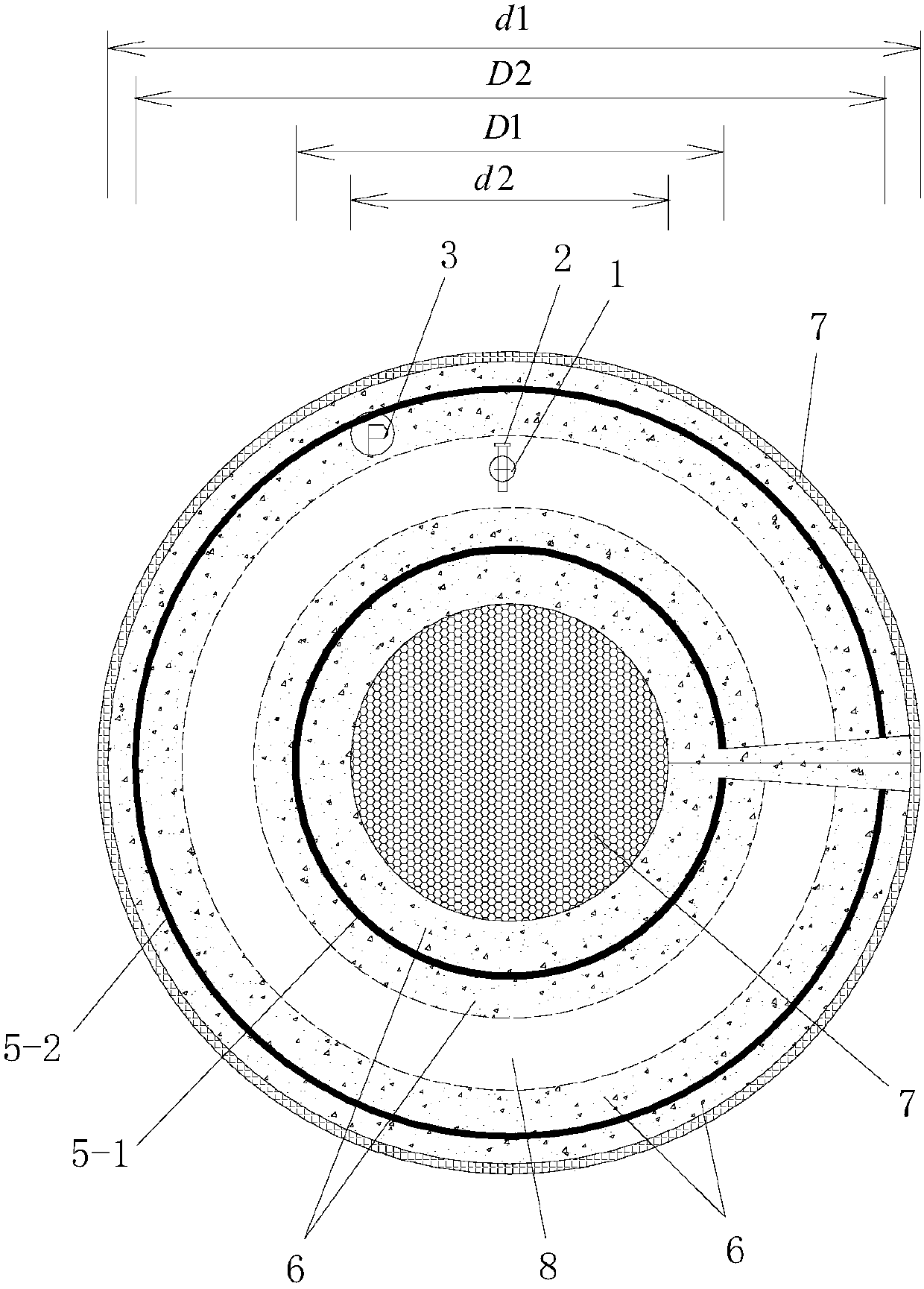

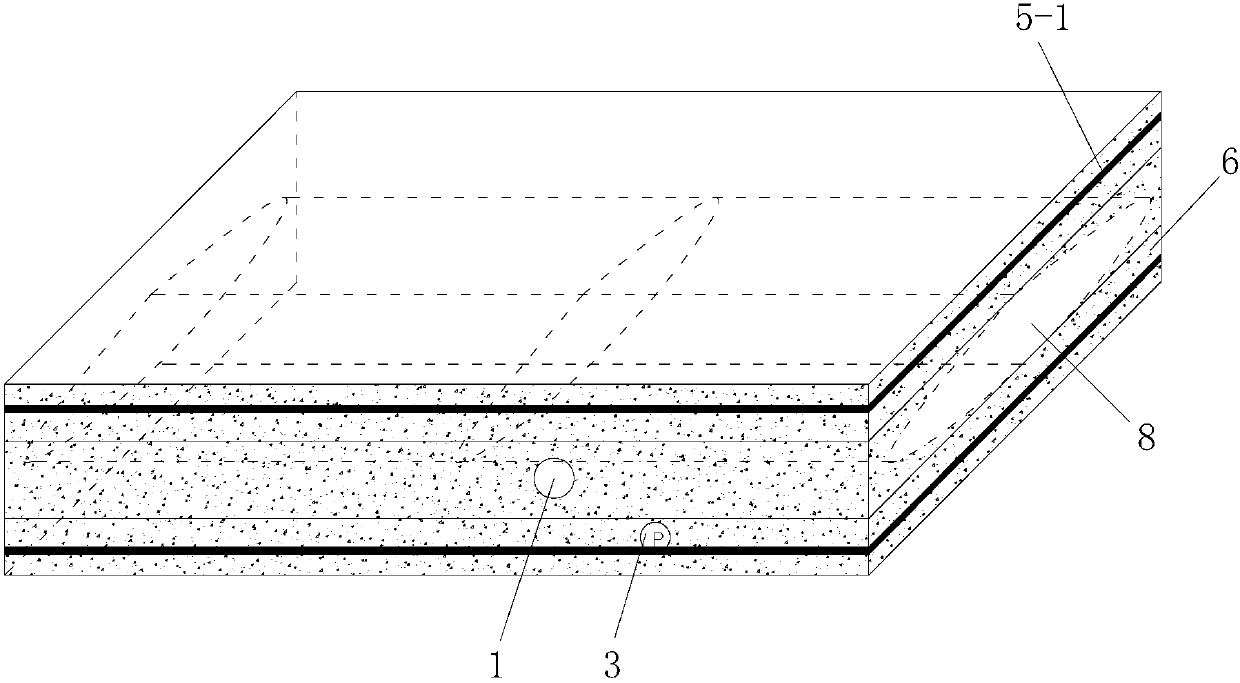

[0037] Such as figure 1 , figure 2 and image 3As shown, the present invention includes an annular rubber sheath 6 that is sleeved between the stay cable 4 and the cable sleeve 7, and the inner steel sheath 5-1, an annular oil bag 8 and The outer steel casing 5-2, the inner steel casing 5-1, the annular oil bag 8 and the outer steel casing 5-2 are arranged from inside to outside and all three are arranged coaxially with the annular rubber sheath 6 ; The inner steel casing 5-1 and the top of the outer steel casing 5-2 are connected by an upper annular steel plate 5-3, and the bottom of the inner steel casing 5-1 and the outer steel casing 5-2 They are connected by the lower annular steel plate 5-4, the upper annular steel plate 5-3 and the lower annular steel plate 5-4 are arranged in the annular rubber sheath 6, the inner steel sheath 5-1, the outer steel sheath The cylinder 5-2, the upper annular steel plate 5-3 and the lower annular steel plate 5-4 form a steel sheath; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com