On-line Evaluation System for Thermal Performance of Modular Heat Exchanger

A technology for evaluating systems and thermal performance, which is applied in the testing of instruments, machines/structural components, measuring devices, etc. It can solve problems such as difficulty in simulating real working conditions and operating environments, and few types of fluids, achieving reliable evaluation and simple and convenient operation. , the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

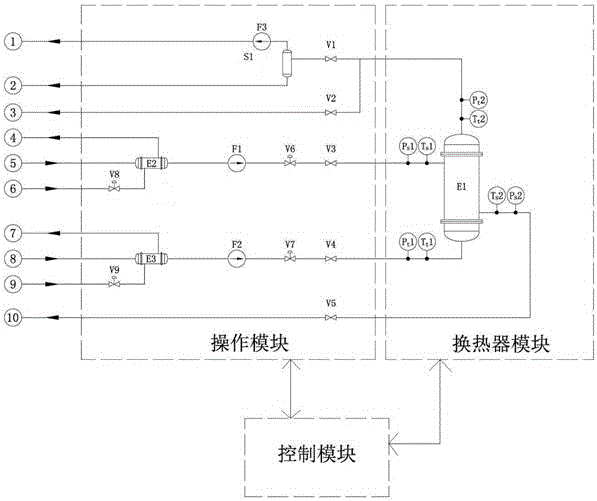

[0019] Such as figure 1 As shown, the present invention discloses an online evaluation system for the thermal performance of a modularized heat exchanger, including an operation module, a heat exchanger module and a control module, and the heat exchanger module includes a tested heat exchanger E1 and a temperature and pressure test module, the shell-side inlet, outlet, tube-side inlet, and outlet of the tested heat exchanger are respectively connected to the shell-side inlet, outlet operation module, tube-side inlet, and outlet operation module of the operation module through pipelines, and the temperature and pressure test The module includes four, the shell side inlet pressure transmitter Ps1, the shell side inlet temperature transmitter Ts1 are set on the pipeline of the shell side inlet of the heat exchanger under test; the shell side outlet pressure transmitter Ps2, the shell side outlet The temperature transmitter Ts2 is set on the pipeline of the shell-side outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com