Low-pressure steam generator

A low-pressure steam and steam generating device technology, applied in the steam generation method using heat carrier, the compression machine with reversible cycle, the compression machine with cascade work, etc., can solve the problem of high pressure of steam generator, container, generation Higher requirements for devices and other issues, to achieve the effect of small temperature fluctuations, ensure safety and stability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

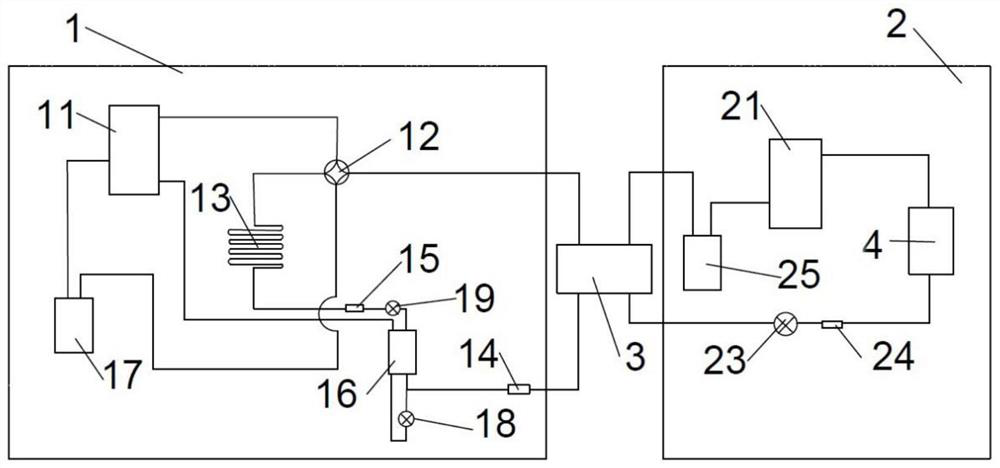

[0026] like figure 1 , figure 2 and image 3 As shown, a low-pressure steam generator provided by the present invention includes a first-stage system 1, a second-stage system 2, and is characterized in that it also includes an intermediate heat exchange regenerator 3, and the second-stage system includes a steam generating device 4. ; The first-stage system 1, the intermediate heat storage heat exchanger 3 and the second-stage system 2 are connected in sequence.

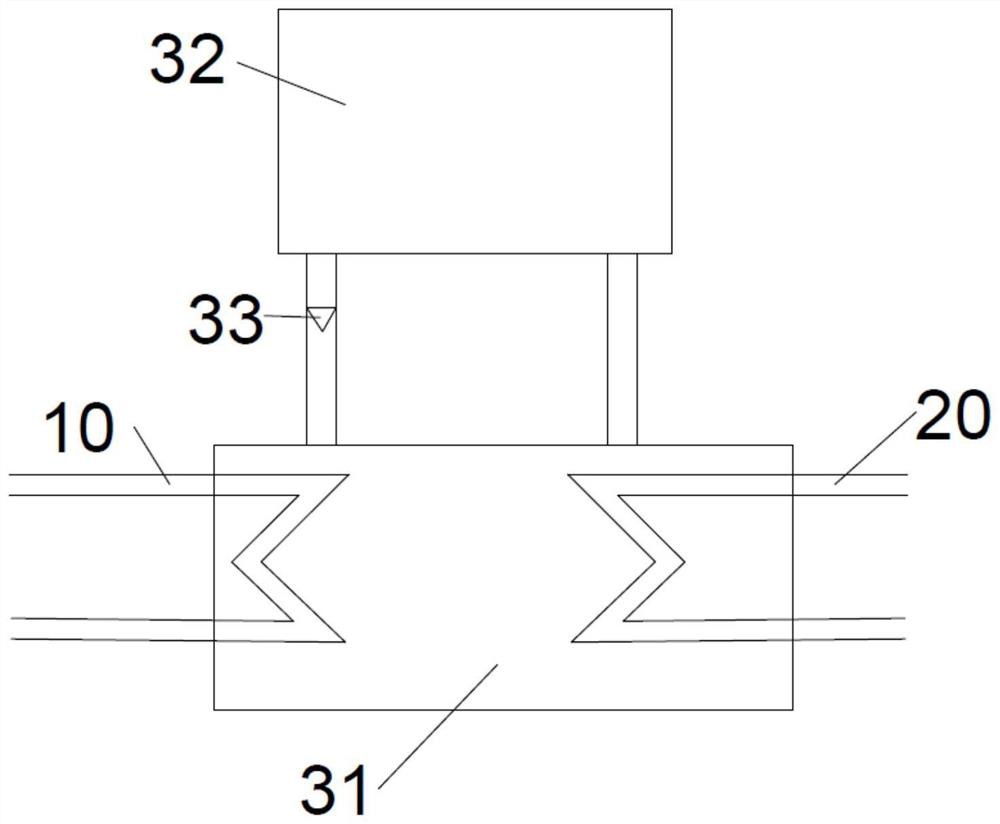

[0027] Further, the intermediate heat exchange regenerator 3 includes a heat exchange chamber 31, an extended liquid storage chamber 32, a heat-carrying solvent and a solution pump 33; the heat exchange chamber 31 and the extended liquid storage chamber 32 pass through two Pipe connection; the solution pump 33 is installed in one of the pipes; the heat transfer solvent is filled in the heat exchange chamber 31 and the extended liquid storage chamber 32 .

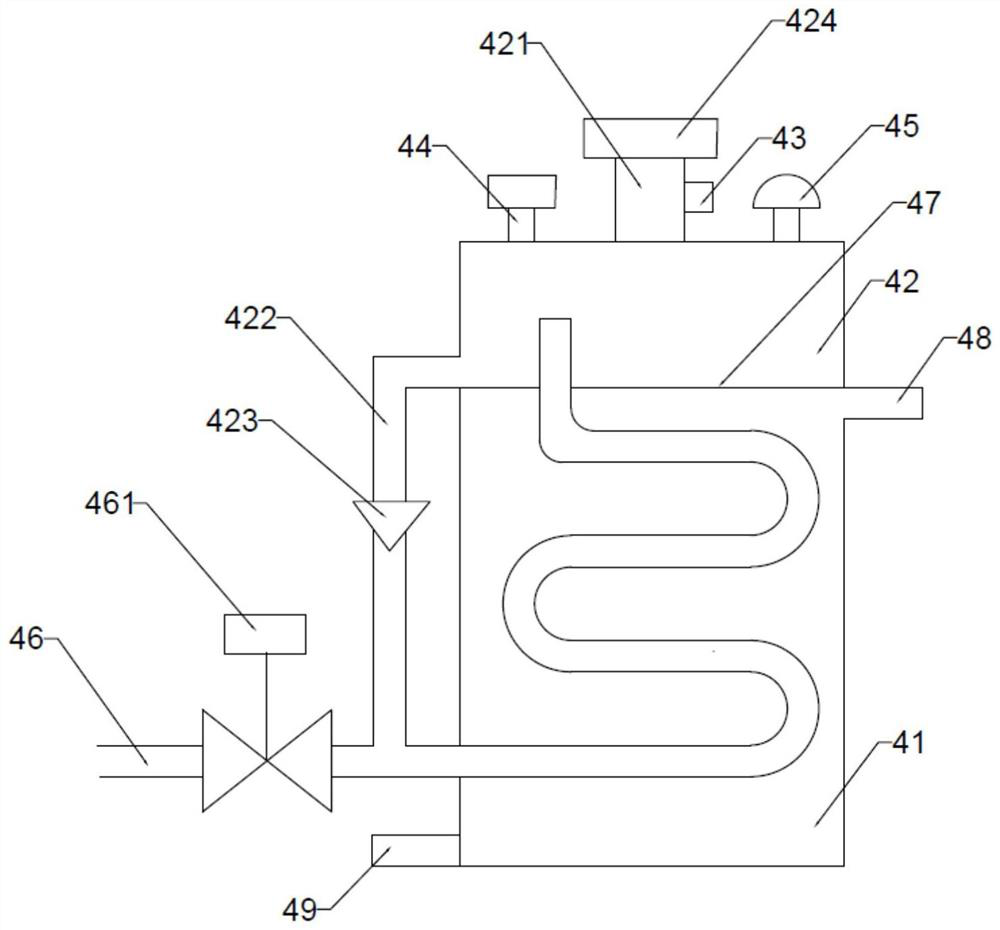

[0028] Further, the steam generating device includes a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com