Formaldehyde removal air purifier

An air purifier and formaldehyde technology, applied in air conditioning systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problem of limited adsorption capacity of formaldehyde air purifiers, non-infinite adsorption capacity of filter elements, and secondary diffusion of formaldehyde and other issues, to reduce the risk of secondary diffusion, slow saturation time, and reduce cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

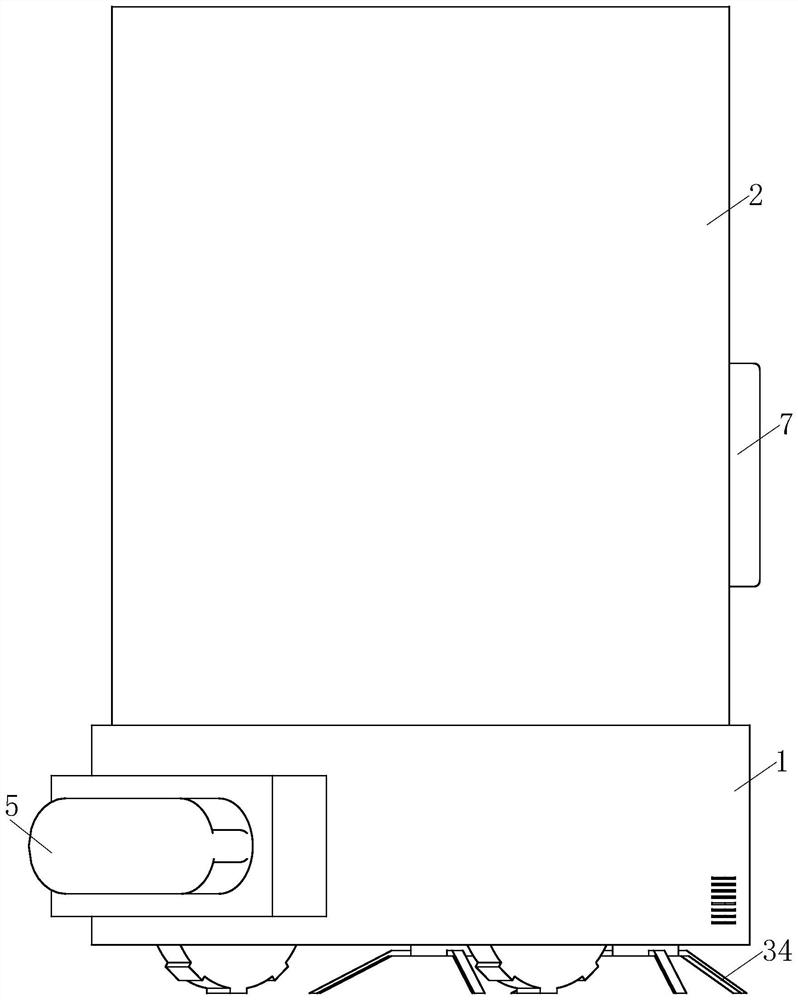

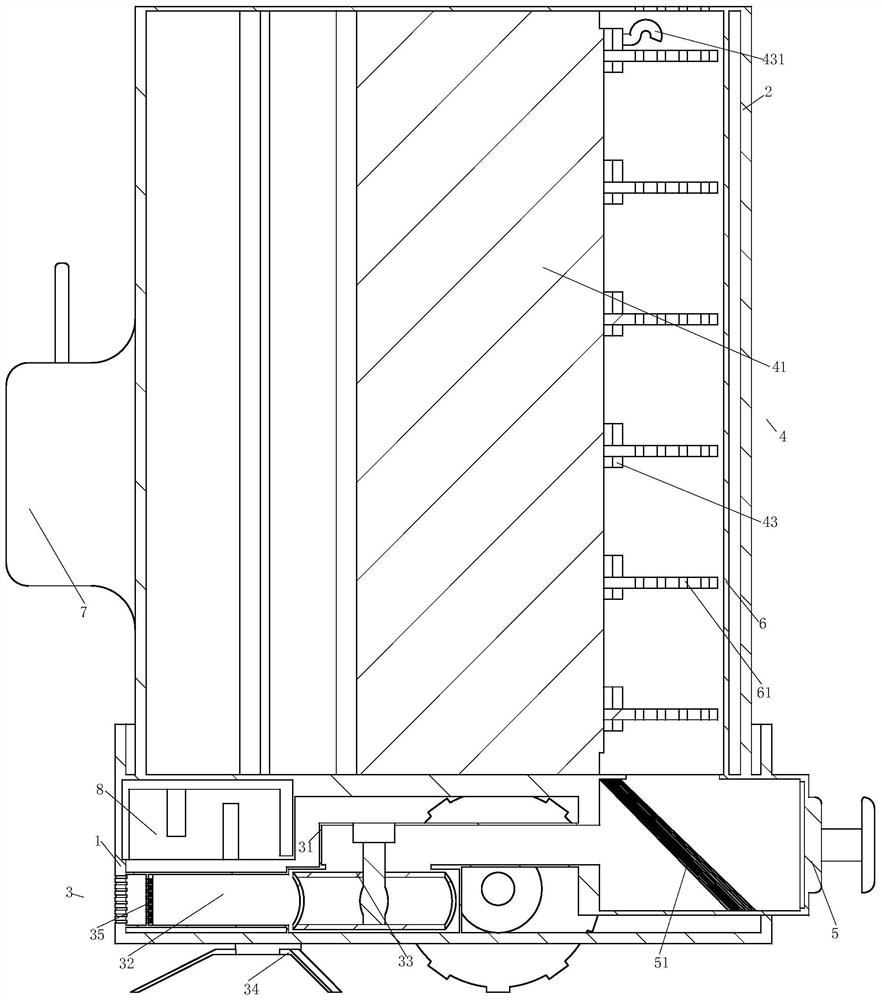

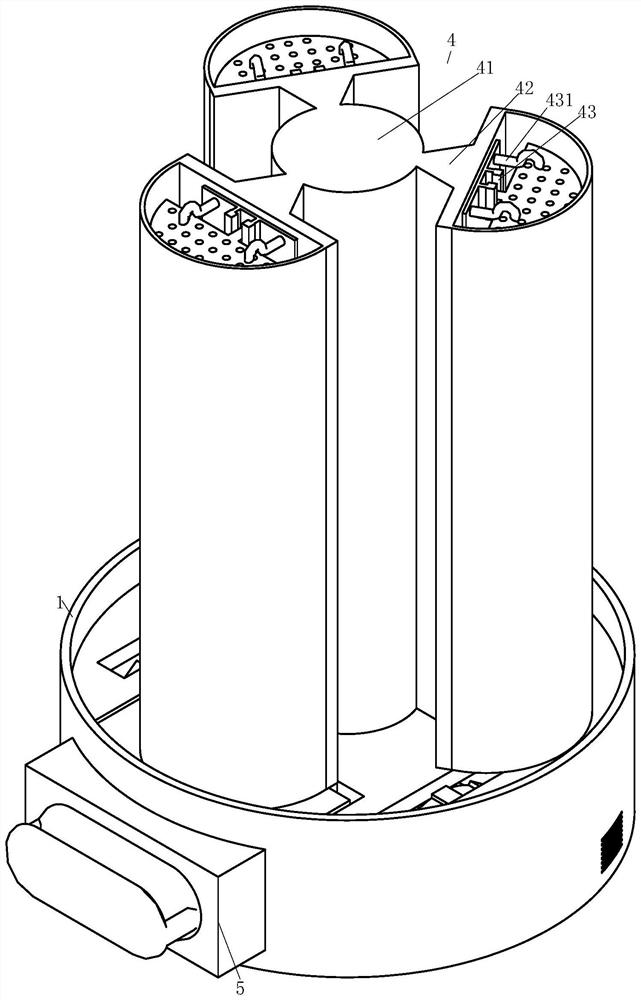

[0048] As an embodiment of the present invention, the filter assembly 3 includes:

[0049] Cover body 31, the cover body 31 is installed inside the cleaning robot body 1;

[0050] The conduit 32, the conduit 32 is placed under the interior of the cleaning robot body 1;

[0051] a fan 33, the fan 33 is installed inside the cover body 31;

[0052] A side brush 34, the side brush 34 is located below the cleaning robot body 1;

[0053] The first-layer filter element 35, the first-layer filter element 35 is placed inside the conduit 32;

[0054] The cover body 31 is fixedly installed at the center of the bottom end of the cleaning robot body 1 and the side wall of the cover body 31 is connected to the three conduits 31. When the cleaning robot body 1 starts to work, it is fixedly installed at the inner upper end of the cover body 31 by the motor. The fan 33 starts to rotate under the drive of the motor. At the same time, the side brush 34 located under the cleaning robot body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com