Drying and digesting device

A drying and sealing box technology, which is applied to heating devices, drying chambers/containers, drying solid materials, etc., can solve problems such as low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

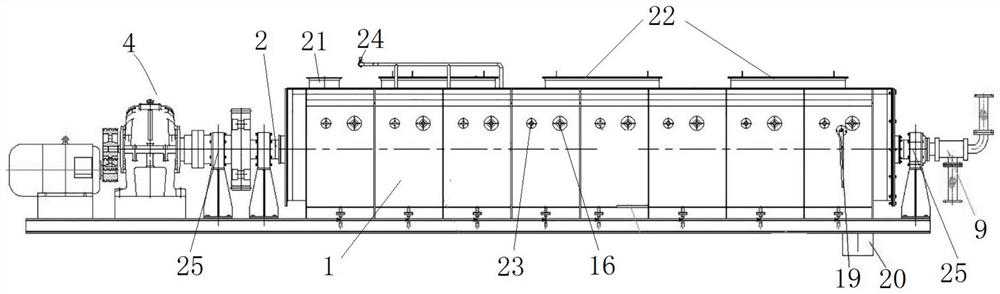

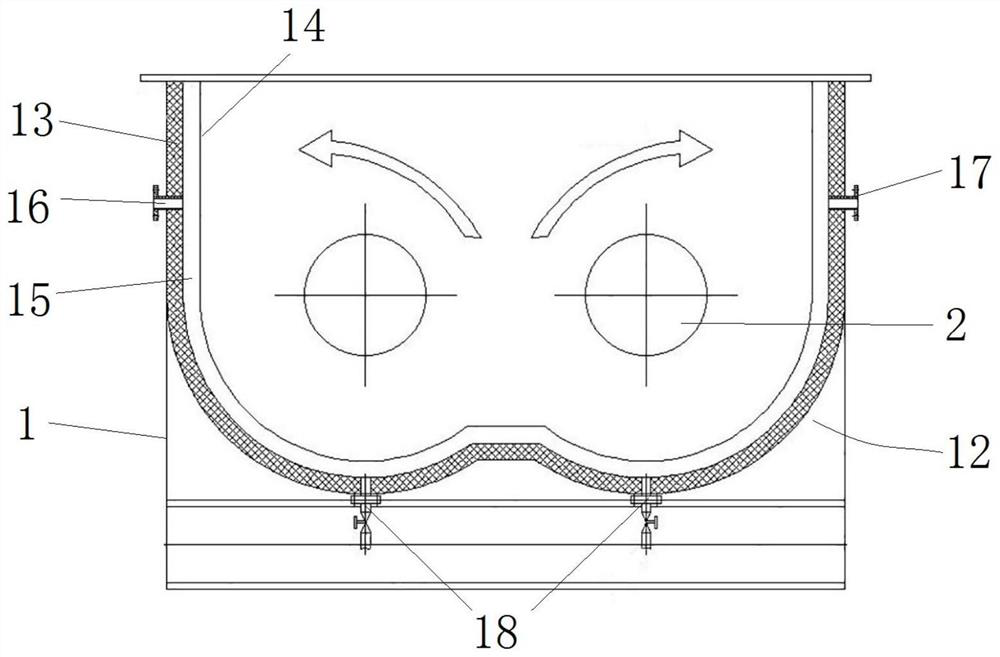

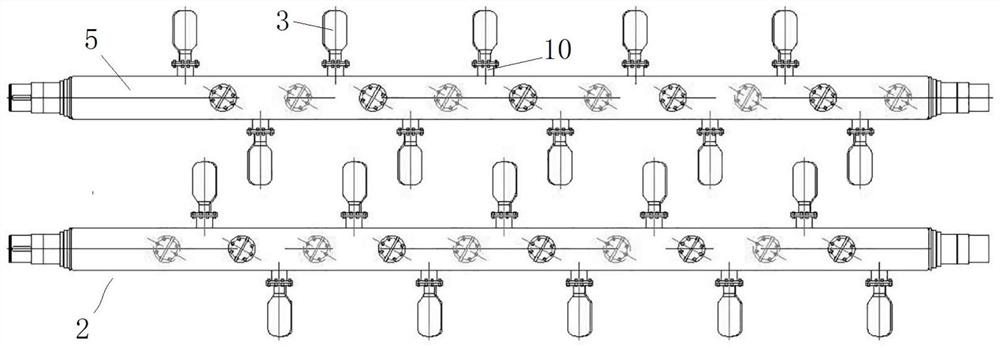

[0032] like Figure 1 to Figure 5 As shown, the drying and digesting device includes a sealing box 1, a power device 4 and two rotating shafts 2 rotatably assembled in the sealing box 1. The sealing box 1 extends forward and backward, and the power device 4 is arranged at the front end of the sealing box 1 and is connected with the two rotating shafts. 2. The transmission connection, the power device 4 is used to drive the rotating shaft 2 to rotate, and the two rotating shafts 2 also extend back and forth and are parallel to each other. The power device 4 in this embodiment is a motor and its configured accelerator. Both are provided with a rotating bearing seat 25, the bearing seat 25 supports the rotating shaft 2 and ensures that the rotating shaft 2 is horizontal. Components such as the power unit 4 and the bearing seat 25 are all in the prior art, and will not be repeated here.

[0033] like figure 1 and figure 2 As shown, the sealing box 1 is a rectangular box structu...

specific Embodiment 2

[0044] The difference from Embodiment 1 is that in Embodiment 1, both the air inlet and the air outlet on the rotating shaft 2 are provided at the rear end of the rotating shaft 2 . In this embodiment, the air inlet of the inner cylinder 6 is set at the front end of the inner cylinder 6 , the air outlet of the outer cylinder 5 is set at the rear end of the outer cylinder 5 , and the air inlet and the air outlet are respectively set at both ends of the rotating shaft 2 . In other embodiments, the rotating shaft can also be a structure with closed ends, that is, the front and rear ends of the inner and outer cylinders are closed, and the air inlet and outlet at this time can be provided on the cylinder walls of the inner and outer cylinders. .

specific Embodiment 3

[0046] The difference from Example 1 is that in Example 1, the drying and digesting device includes a rotary joint 9 disposed on the rear side of the sealing box 1 , and the rotary joint 9 is a three-way joint. In this embodiment, the rotary joint is replaced with an air valve. In other embodiments, the rotary joint is eliminated, and the rear end of the rotary shaft extends out of the bearing seat and is directly connected to the trachea, and the trachea is used to connect the ventilation equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com