Supply auxiliary device for stuffed toy production

A technology for auxiliary devices and plush toys, which is applied in the direction of toys, packaging, transportation and packaging, etc., and can solve problems such as increased labor costs and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

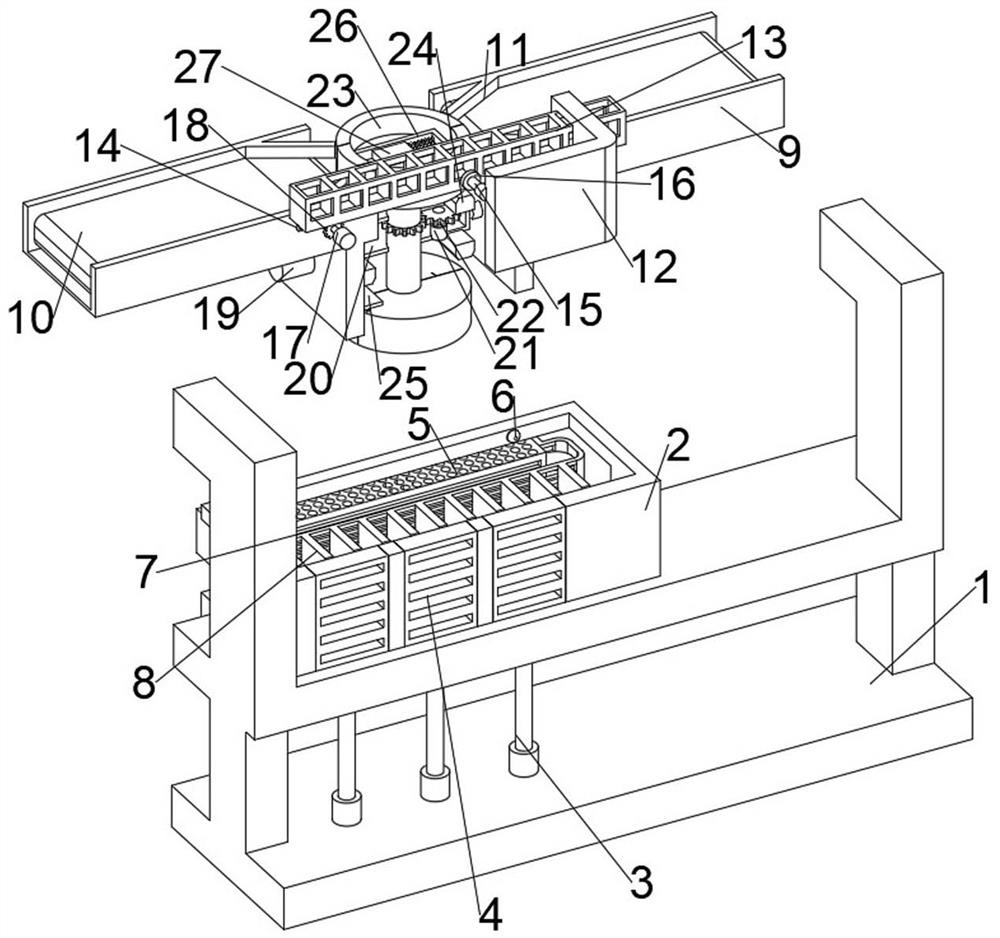

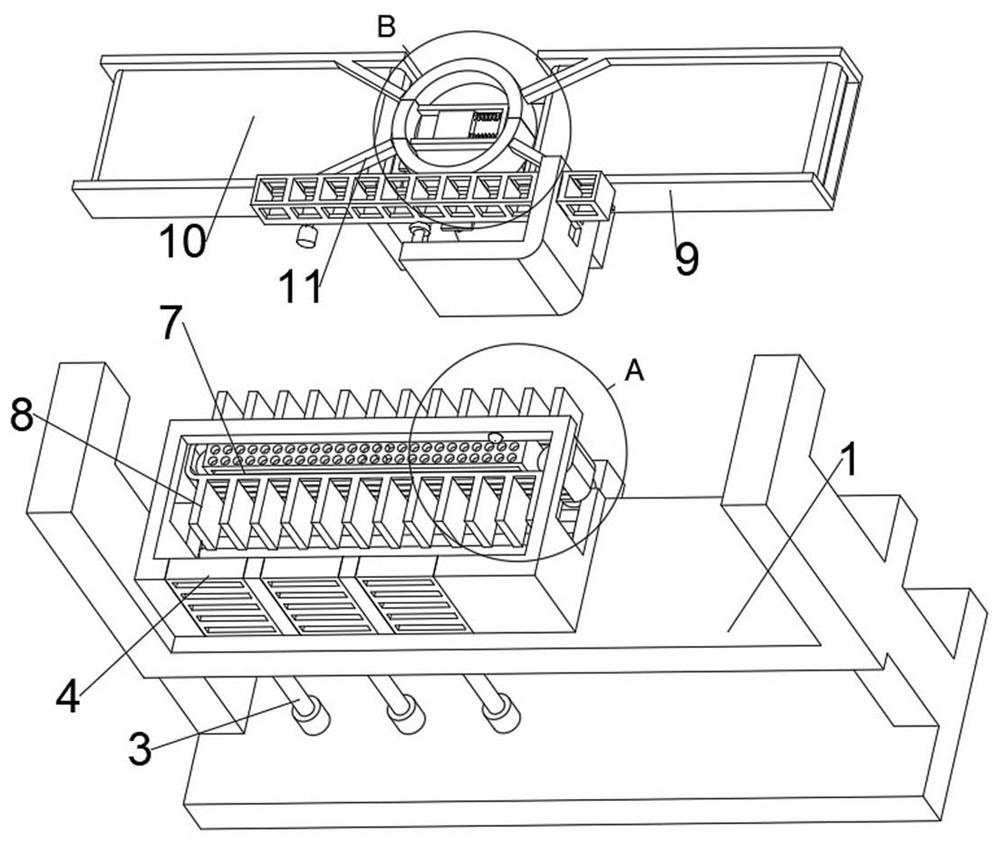

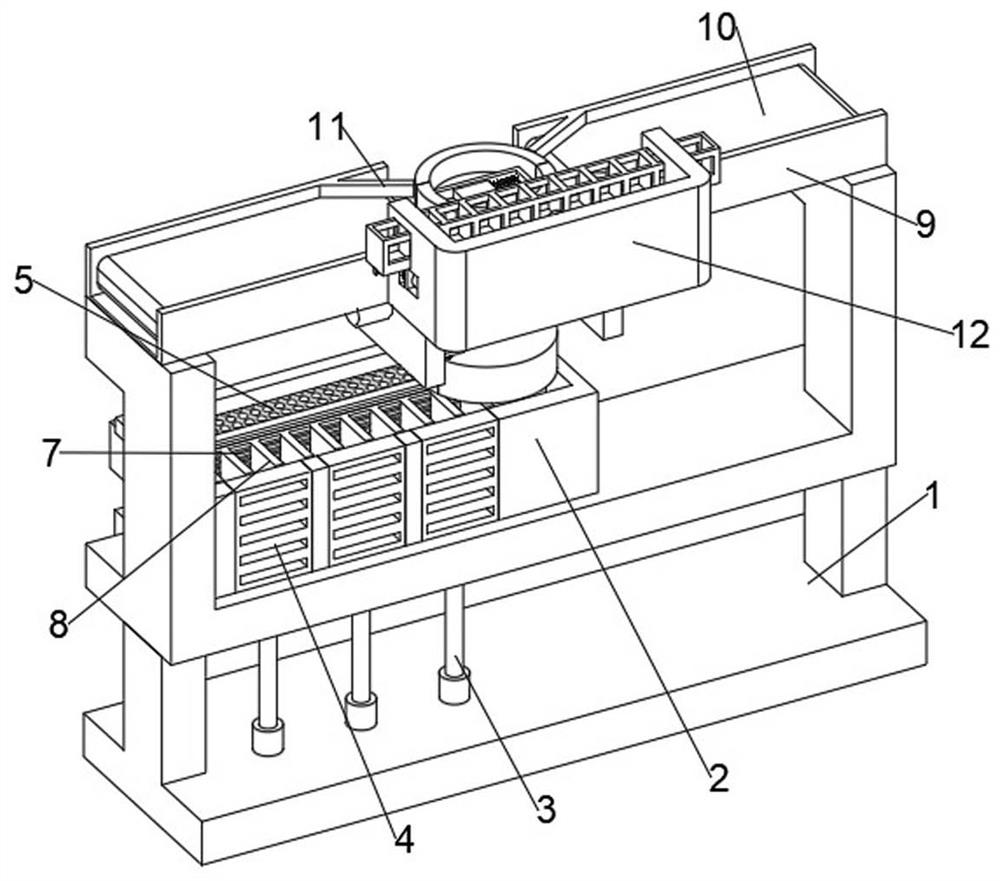

[0030] Example: please refer to Figure 1 to Figure 8 :

[0031] The present invention proposes a supply auxiliary device based on the production of plush toys, comprising: a base 1, the main body of the base 1 is a rectangular double-layer structure, and the upper part of the base 1 is fixedly connected with a frame body 2, and the interior of the base 1 An electric push rod A3 is installed in a linear array, and a baffle 4 is installed at the top of the electric push rod A3. The interior of the baffle 4 is a rectangular array with through grooves, and the baffle 4 is used to close the frame body 2. A fan 5 is installed inside, and the fan 5 is used to discharge air to the front side. A toggle belt 7 is also installed on the top of the frame body 2. The top and bottom ends of the rotating shafts installed in the bearing seat 20 are equipped with a bearing plate 23. The plate 23 is a ring-shaped structure, and two electromagnetic seats 24 are installed on the top, upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com