Hatch coaming structure of ultra-large container ship

A container, super-large technology, applied in the direction of ship hatches/hatch, hull, ship construction, etc., can solve the problems of no design sealing structure and easy water seepage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

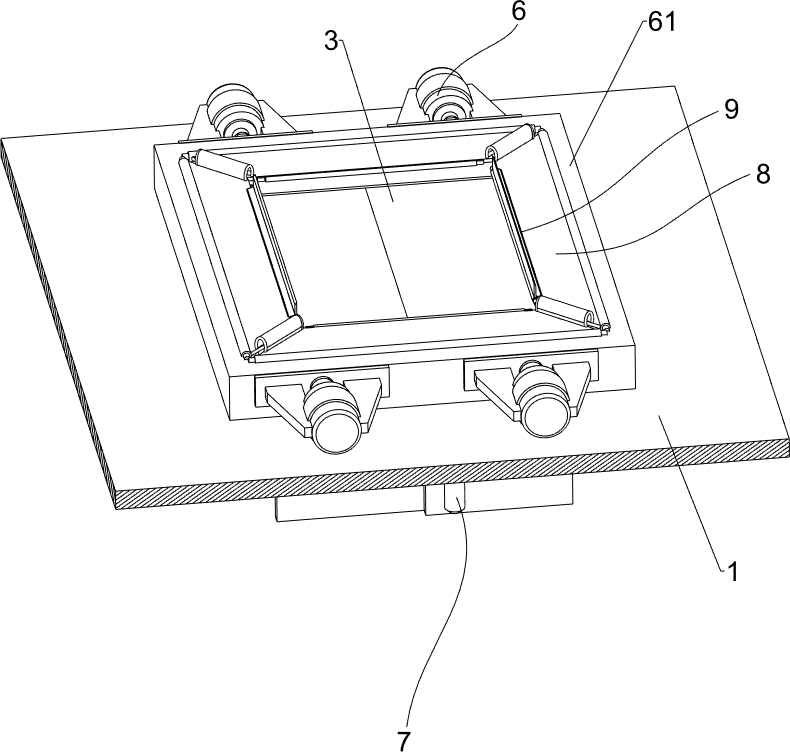

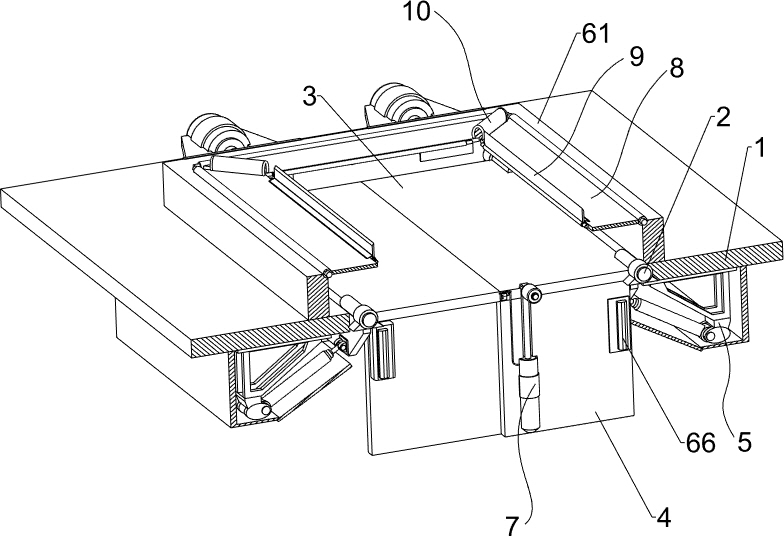

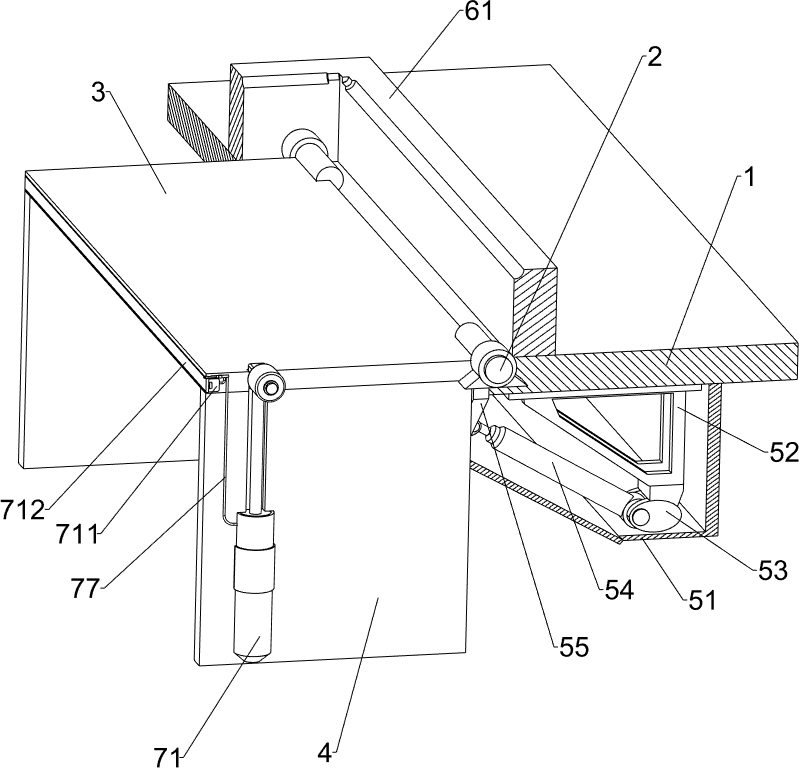

[0033] A hatch coaming structure of an ultra-large container ship, refer to Figure 1-Figure 7 , including a rotating shaft 2, a cover plate 3, a side plate 4, a driving assembly 5, a locking assembly 6 and a sealing assembly 7, the left and right sides of the upper part of the hatch plate 1 are rotatably provided with a rotating shaft 2, and the left and right two rotating shafts 2 are There is a cover plate 3. After the cover plate 3 is turned downward and closed, it can play the role of dustproof and waterproof, and prevent water from infiltrating into the cabin. Side plates 4 are welded on the front and rear sides of the bottom of the cover plate 3. The side panels 4 are arranged in a staggered manner, so that the side panels 4 will not collide when they are rotated upward. The bottom of the hatch panel 1 is provided with a drive assembly 5, the outer side of the side panel 4 is provided with a locking assembly 6, and the outer side of the side panel 4 is provided with a se...

Embodiment 2

[0039] On the basis of Example 1, refer to figure 1 , figure 2 , Figure 8 and Figure 9 , also includes a closing assembly 8, the closing assembly 8 includes a hinge plate 81, a rotating rod 82, a roller 83, a limit block 84 and a second spring 85, and the upper, front, rear, left, and right sides of the upper part of the fixed frame 61 are rotatable. 81. The hinge plate 81 can block the gap between the cover plate 3 and the hatch plate 1. The inside of the hinge plate 81 is rotatably provided with a rotating rod 82, and the rotating rod 82 is equipped with a rotating roller 83, and the cover plate 3 is upward. The rotation will come into contact with the roller 83 , the limit blocks 84 are welded on the front, rear, left and right sides of the upper inner side of the fixed frame 61 , the top of the limit blocks 84 are all in contact with the adjacent hinge plates 81 , and the bottom of the hinge plates 81 is between the inner wall of the fixed frame 61 . Both are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com