Box part bowl-shaped plug press-fitting clamp

A technology for bowl-shaped plugs and parts, which is applied in the field of bowl-shaped plug press-fitting fixtures for box parts, can solve problems such as high labor intensity, large floor space, and complicated equipment maintenance, and achieve low labor intensity, low labor intensity, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

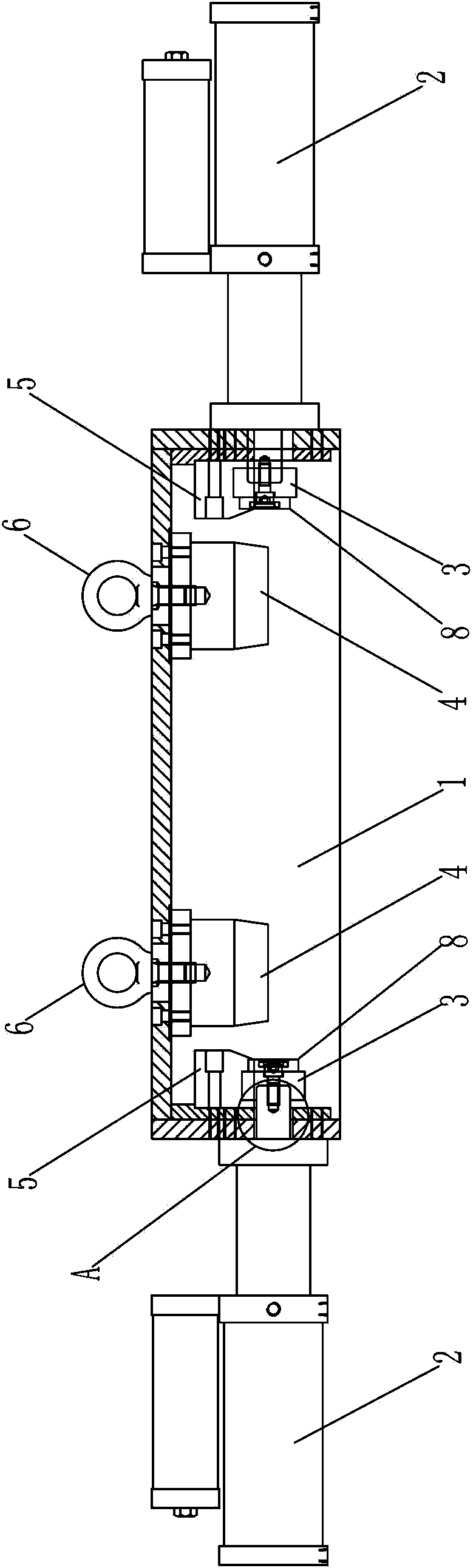

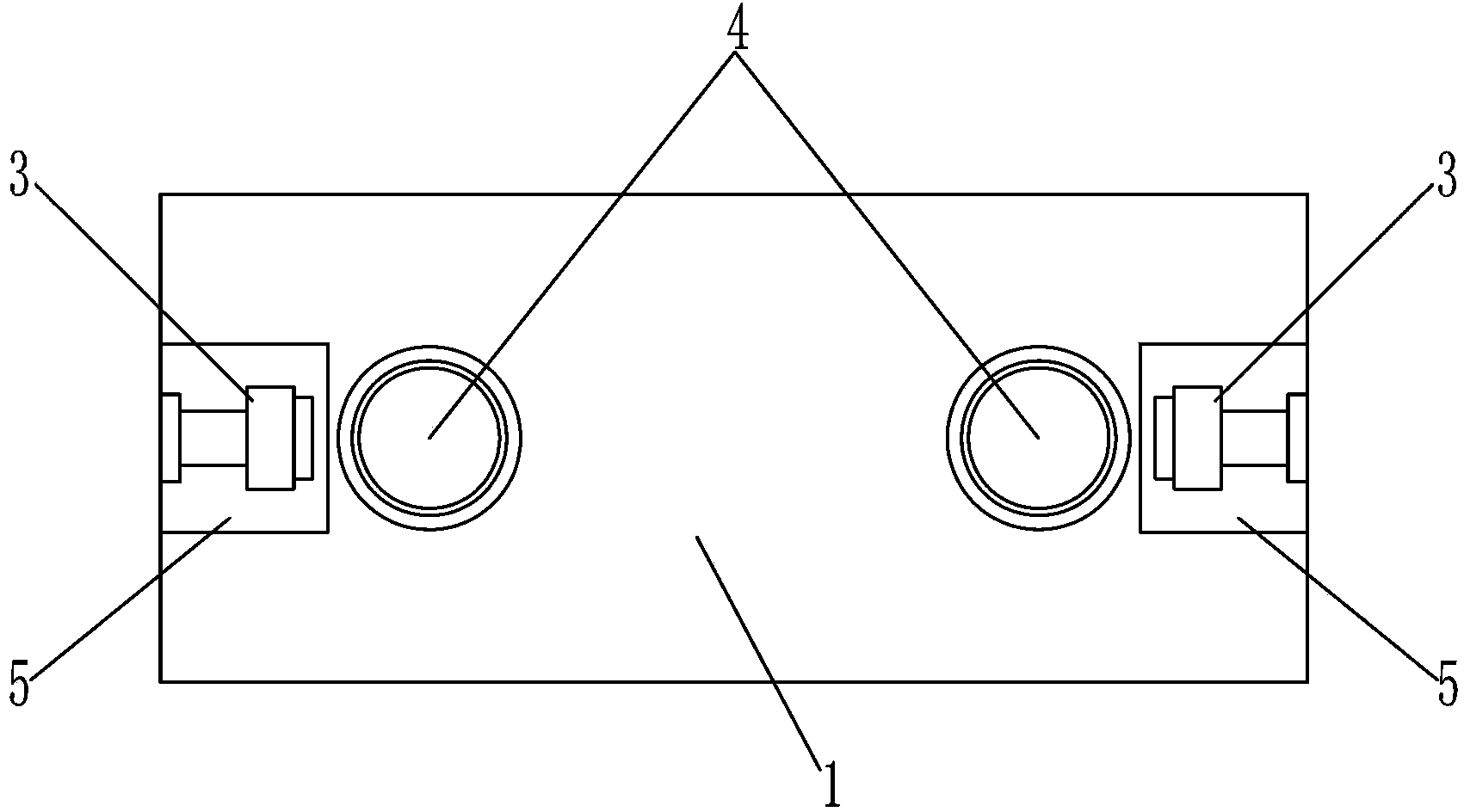

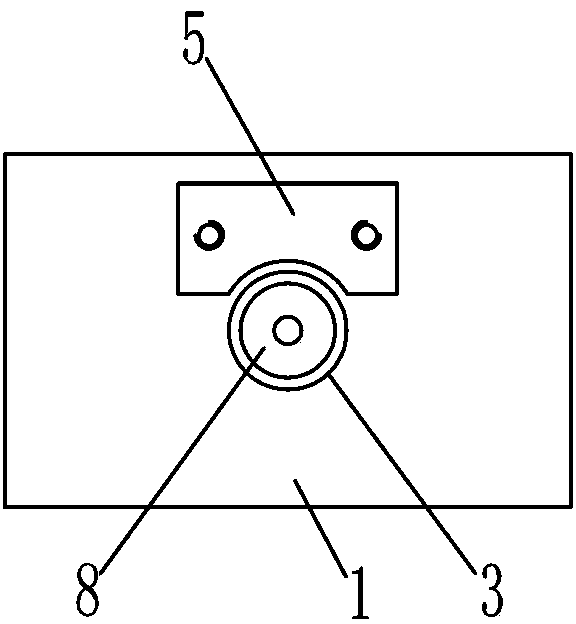

[0022] Such as figure 1 The shown bowl-shaped plug press-fitting fixture for box body parts includes a clamp body 1 whose inner cavity is adapted to the outer contour of the box body part 7, and the two sides of the clamp body 1 correspond to the sand outlet holes of the box body part 7. Cylinders 2 are respectively arranged at the positions, the telescoping ends of the cylinders 2 face the inner chamber of the clamp body 1 , and the telescoping ends of the cylinders 2 are provided with floating pressure heads 3 . By adding a cylinder 2 with a floating pressure head 3 on the clamp body 1, the clamp is fastened on the box part 7, and the cylinder 2 is driven to make the floating pressure head 3 press the bowl-shaped plug into the The sand hole of the box part 7 is sufficient, the structure is simple, the cost is low and the labor intensity is small. The telescopic end of the cylinder 2 passes through the clamp body 1 and is connected to the floating pressure head 3, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com