A movable steel strand threading guide device and its application method

A technology for steel strands and bundling, which is applied in the field of movable steel strand bundling guides, can solve the problems of inability to meet bundling requirements, economic losses in construction, and difficulty in operation, and achieves construction quality, safety and convenience. The effect of controlling, saving construction costs and improving traction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

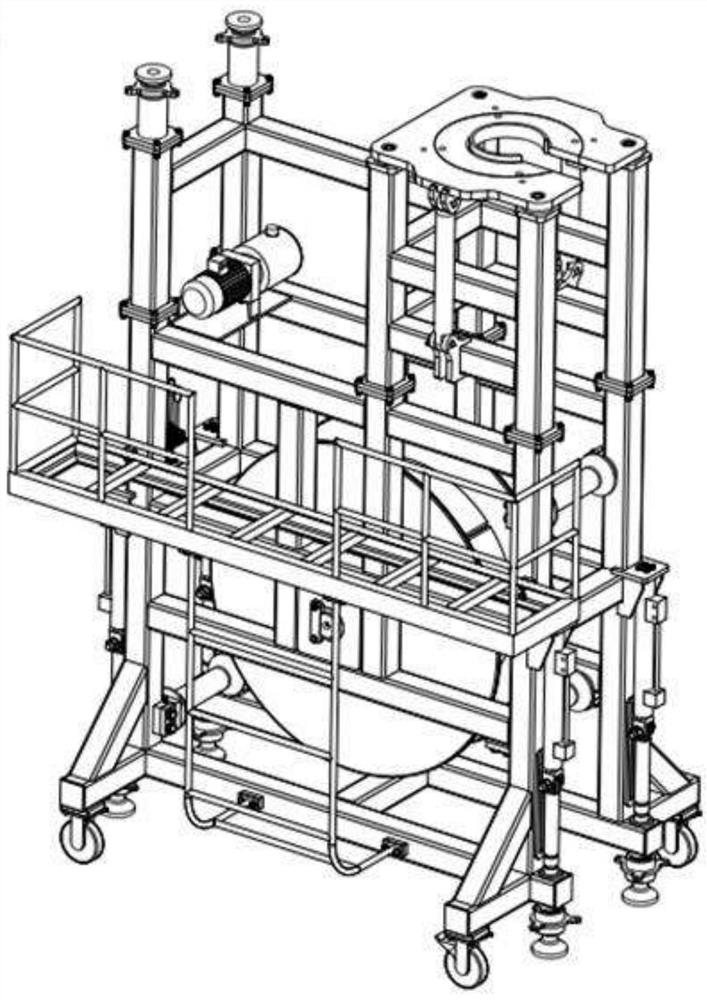

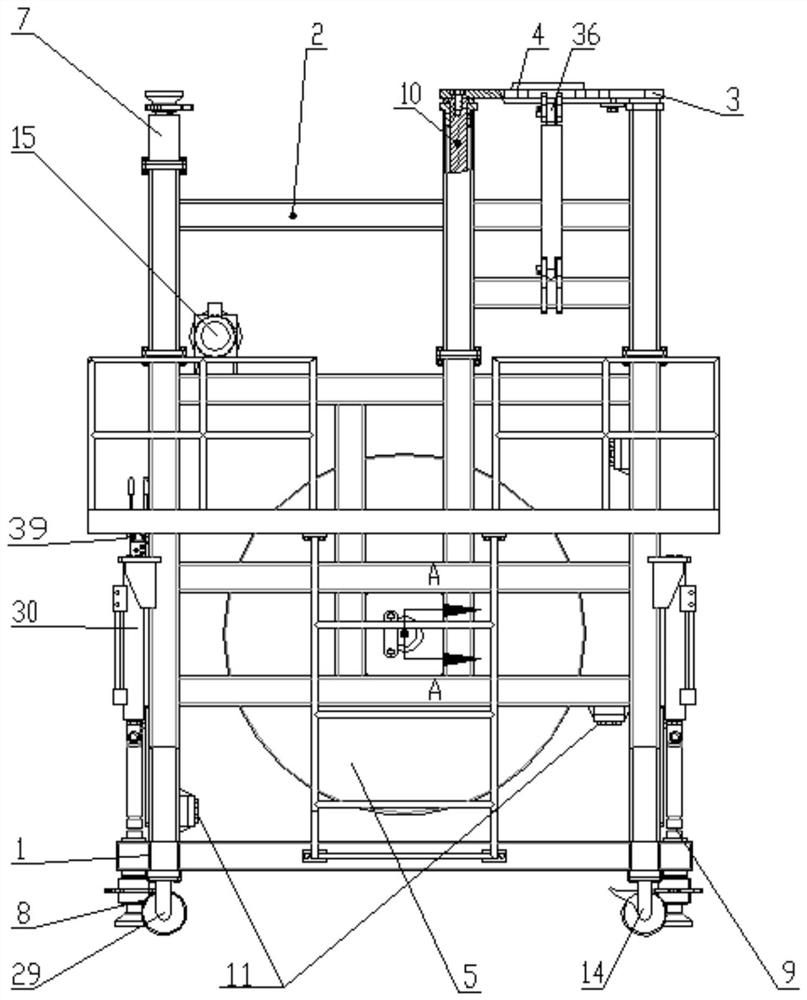

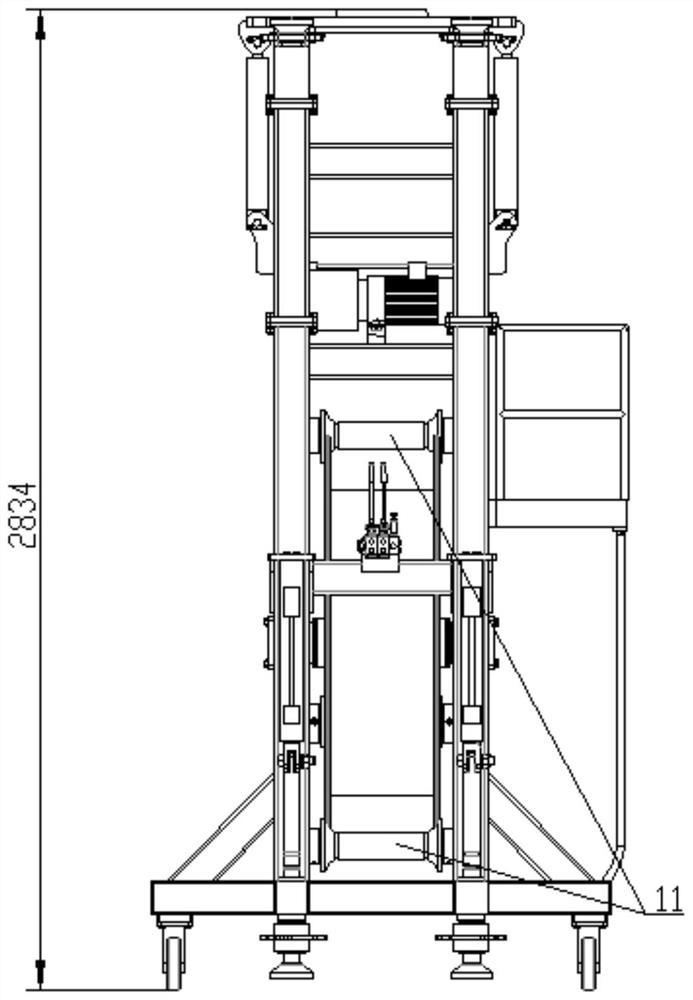

[0021] The present invention will be further described below in conjunction with specific examples.

[0022] A movable steel strand threading guide device, including a frame, a guide roller 5, a top tightening device and a frame lifting device; the frame is composed of a lower frame 1, an upper frame 2 and a lifting device 3, and the guide roller 5 is located in the formed frame, the lifting device 3 includes a threaded jack 7, a threaded sleeve 8, a jack rod 9 and a lifting device cylinder 30, and the jacking device includes a butt plate 4 and a jacking jack cylinder, and the jacking device is tightened The docking plate 4 of the device is aligned with the steel pipe pressure plate; the frame lifting device includes an operating valve 39 and a hydraulic pump station 15 for controlling the frame lifting.

[0023] The front universal caster 14 and the rear directional caster 29 are provided below the frame to control the front and rear movement.

[0024] The jack cylinder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com