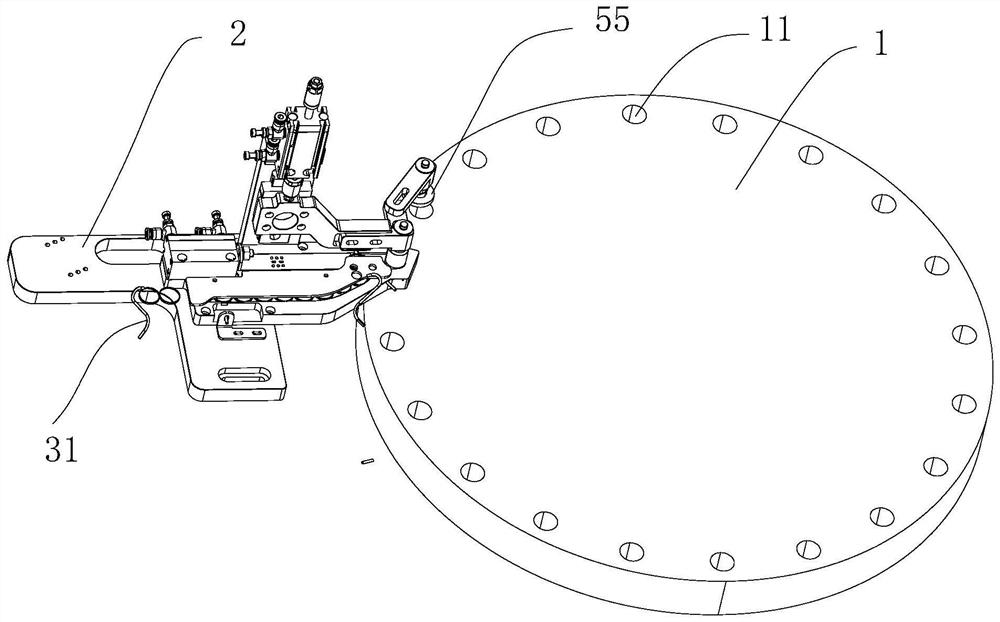

Soft metal ring blanking device and blanking method

A soft metal and metal ring technology, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as deformation of flexible metal rings, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

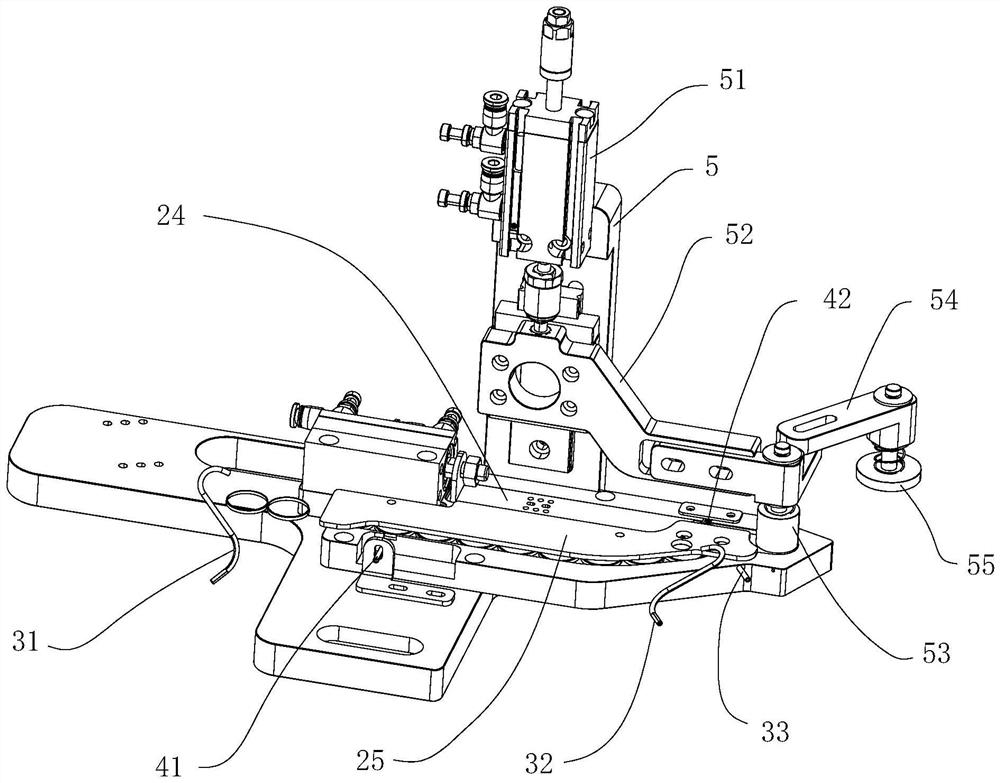

[0105] A method for blanking a soft metal ring is provided, using the soft metal ring blanking device of Embodiment 1, comprising the following steps:

[0106] Step S01, the metal ring is transported to the material preparation station;

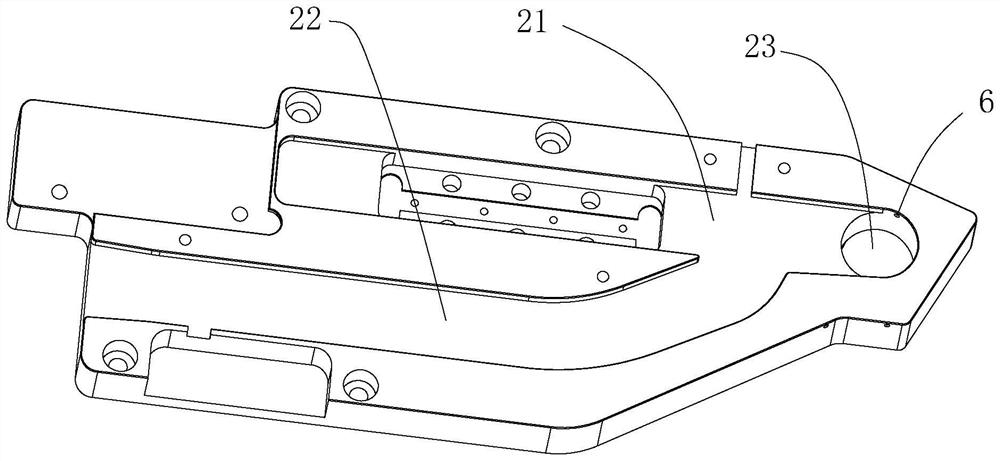

[0107] In step S02, the pusher plate 24 pushes the metal ring to move toward the front blanking station. When the metal ring has not completely entered the blanking station, the metal ring is sucked into the blanking station by the two metal rings in the blanking station. In position, the metal ring at this time is located above the blanking hole 23;

[0108] In step S03, the blanking head 53 moves downward, and drives the metal ring to move out of the blanking hole 23, and enters the mold cavity 11 of the lower turntable 1 to complete blanking.

[0109] The cutting method of the soft metal ring in this embodiment can prevent the metal ring from being deformed when the pusher plate 24 pushes the metal ring, thereby improving the yield of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com