Small-lifting-distance crane for hoisting templates and molds

A kind of crane and mold technology, applied in the direction of hoisting device, traveling mechanism, transportation and packaging, etc., can solve the problems of short lifting height, difficult control, complex structure, etc., to achieve short lifting stroke, improve production efficiency, work smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

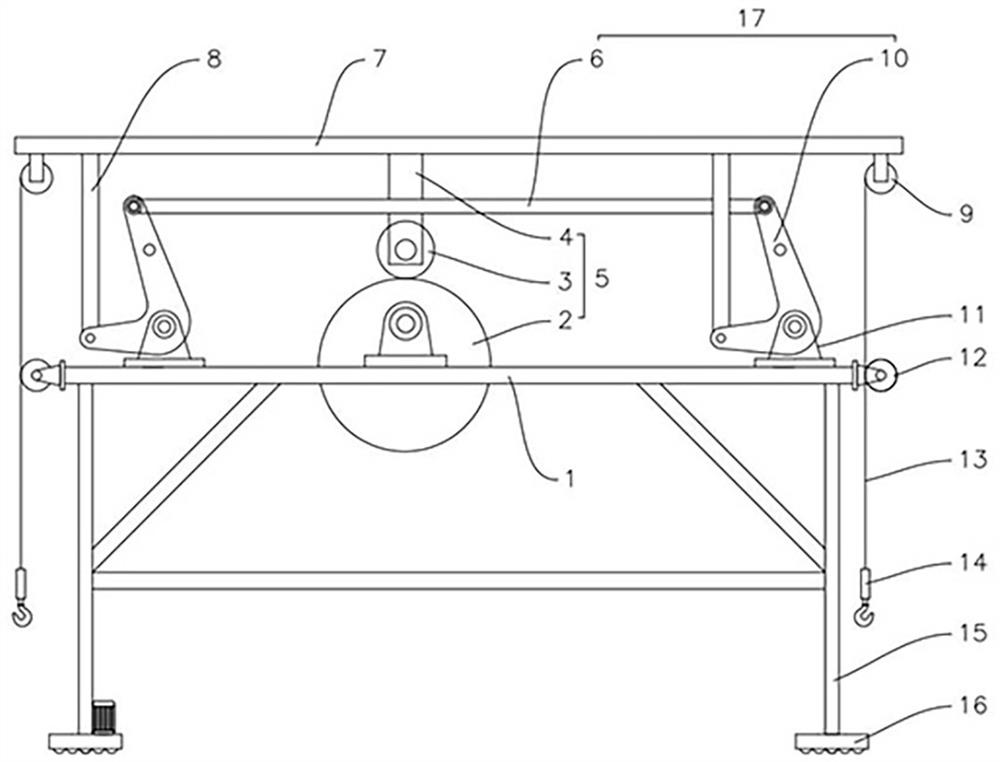

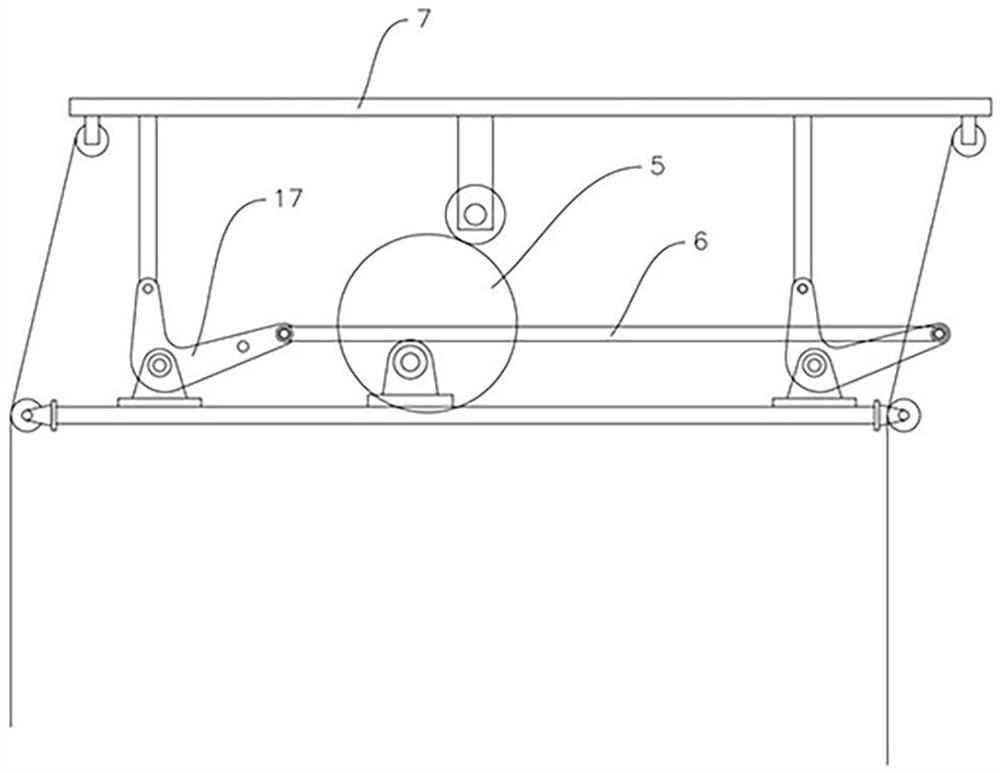

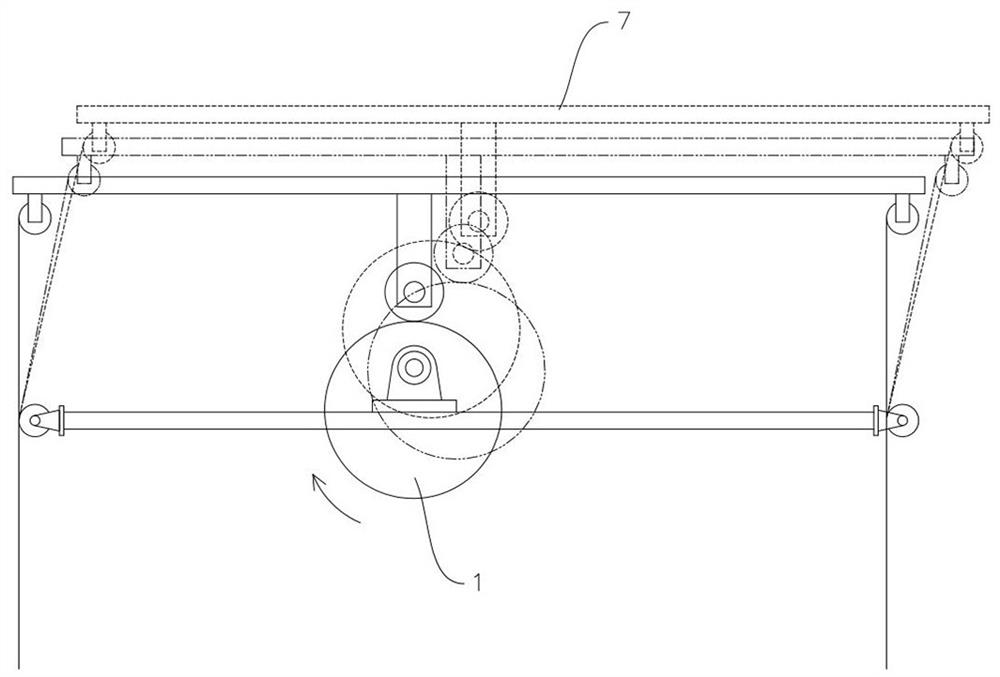

[0029] see Figure 1-Figure 6 , The present invention provides a small lifting distance crane for template and mold hoisting, including a frame 1; the frame 1 is the installation base of each component on the crane. The top of the frame 1 is provided with a lifting frame 7 that moves up and down, and support rods 8 are fixed at both ends of the lifting frame 7; For lifting and lowering, the lifting and lowering of the crane frame 7 needs to be equipped with a driving mechanism, and the driving mechanism can be a cam jacking mechanism 5 or a hydraulic jacking mechanism. The drive mechanism is arranged between the frame 1 and the crane frame 7 . Both ends of the frame 1 are rotatably connected with a synchronous swing mechanism 17 for balancing the crane frame 7 ; the first end of the synchronous swing mechanism 17 is rotatably connected with the corresponding support rod 8 above. Since the crane is used for lifting and transporting materials, when the materials are heavy and ...

Embodiment 2

[0039] see Figure 1-Figure 7 , the present invention provides a small lifting distance crane for template and mold hoisting. The following technical description is made from another aspect, so as to better understand the technical solution.

[0040] A small lifting distance crane for hoisting templates and molds, comprising a frame 1; a lifting frame 7 that moves up and down is arranged above the frame 1, and support rods 8 are fixed at both ends of the lifting frame 7; Both ends of the frame 1 are rotatably connected with a synchronous swing mechanism 17 for balancing the crane frame 7; A synchronous pull rod 6 is arranged between the synchronous swing mechanism 17; the end of the synchronous pull rod 6 is rotatably connected to the second end of the synchronous swing mechanism 17; the synchronous swing mechanism 17 or the hoisting frame 7 is connected with a lifting cable 13 , the free end of the hoisting cable 13 is connected with a hook 14; the two ends of the frame 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com