Production device and process of bamboo fiber, cotton fiber and acrylic fiber blended sanded fabric

A production device and cotton fiber technology, applied in the field of fabric production, can solve the problems of lack of gray cloth desizing treatment, affecting the water absorption performance of fabrics, poor dyeing effect of gray cloth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

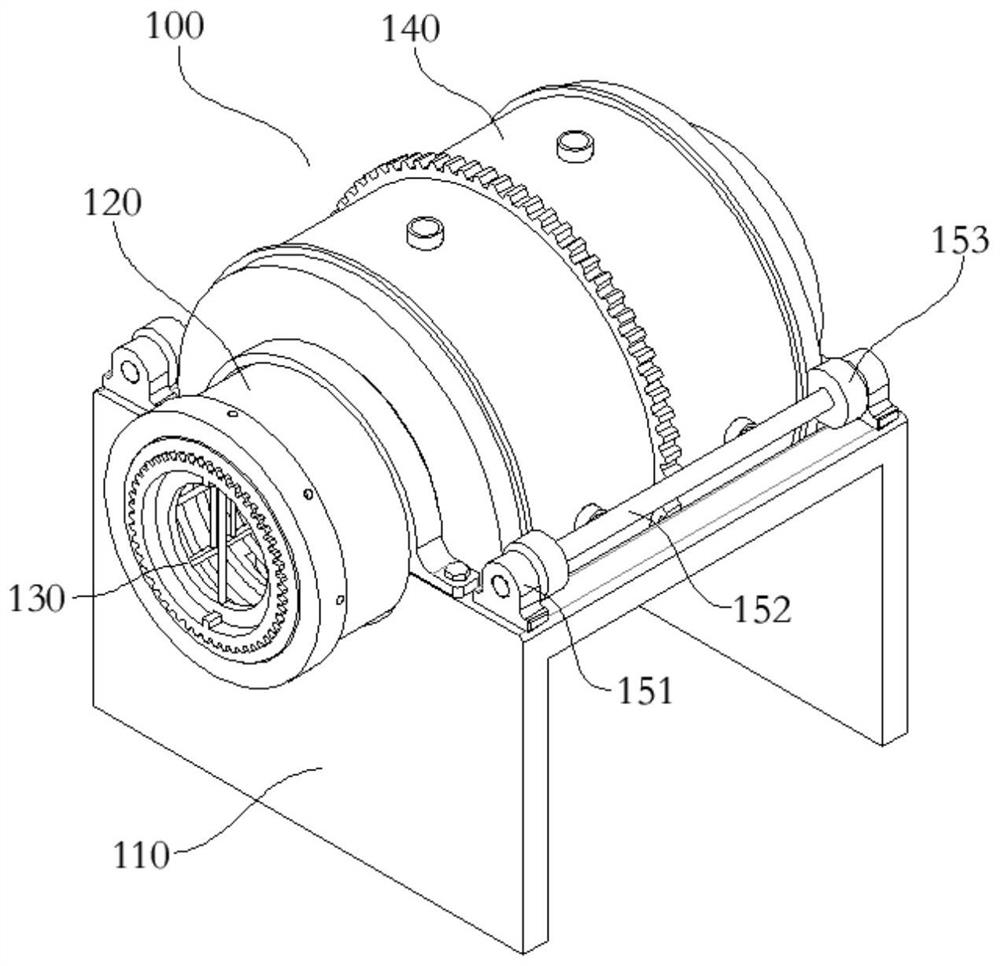

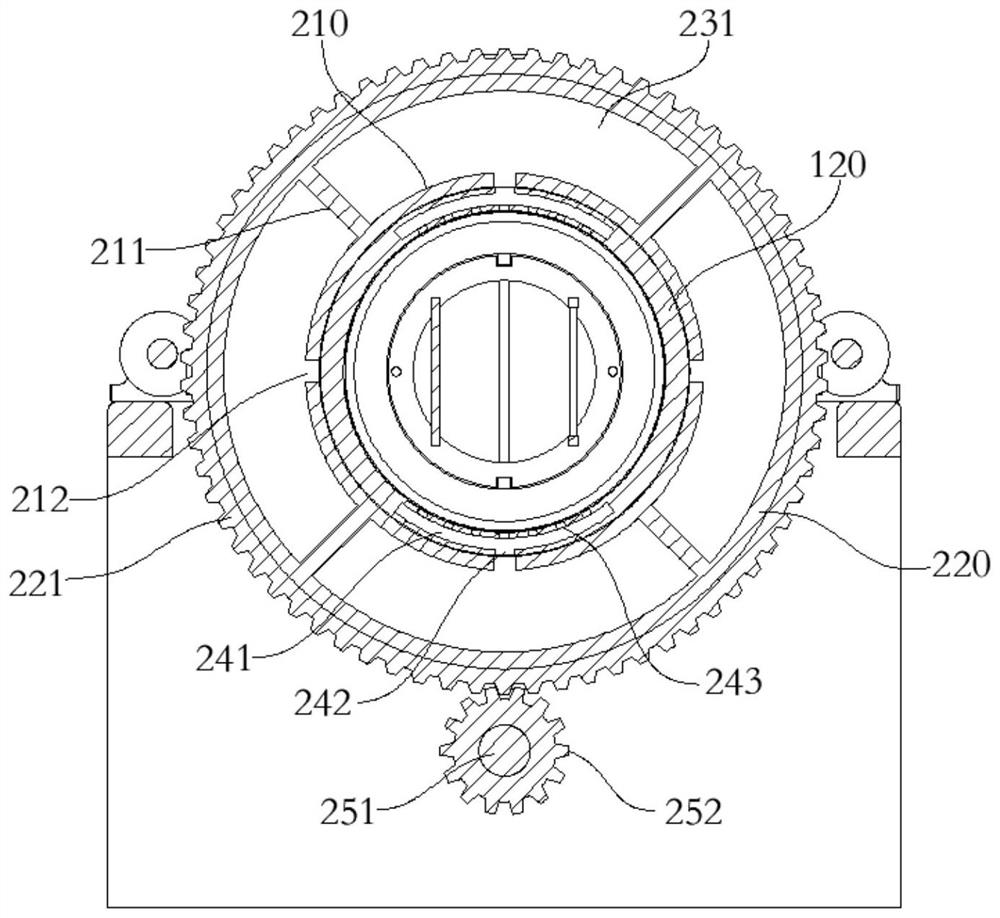

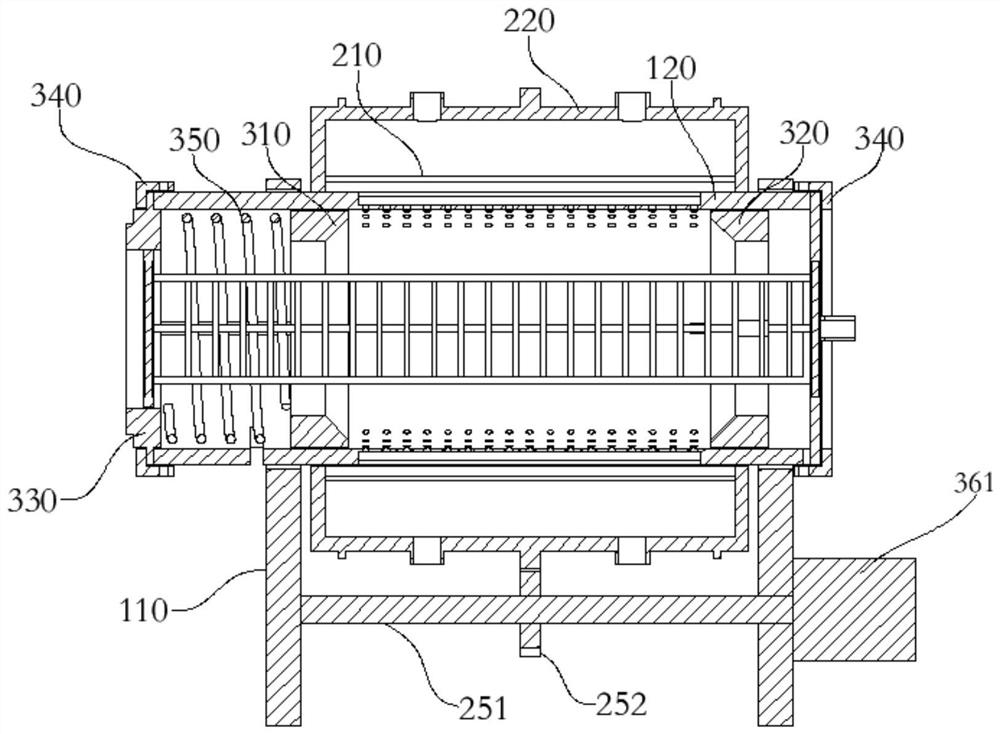

[0052] like Figures 1 to 2 As shown, this embodiment provides a production device for fabrics made of bamboo fiber, cotton fiber and silk, which includes a desizing device 100, and the desizing device 100 includes a mounting frame 110. The mounting frame 110 is provided with a The fixed cylinder 120 with openings at both ends, the fixed cylinder 120 is used for the embryo cloth to pass through;

[0053] A cavity 241 with an arc-shaped cross-section is symmetrically arranged in the side wall of the fixing cylinder 120 and located at the upper and lower sides. a drain groove 242, the side wall of the cavity 241 is evenly distributed with spray holes 243 communicating with the fixing cylinder 120;

[0054] The outer cover of the fixed cylinder 120 is provided with a rotatable liquid storage tank 140. The liquid storage tank 140 includes an inner cylinder 210 which is sliding and airtightly matched with the outer wall of the fixed cylinder 120 and an outer cylinder 220 coaxially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com