Waterproof system of urban tunnel structure

An authentic and urban technology, applied in waterway systems, sewer systems, dams, etc., can solve problems such as the difficulty of instantly discharging a large amount of accumulated water, so as to ensure safety, avoid excessive accumulated water, and increase the space for water storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

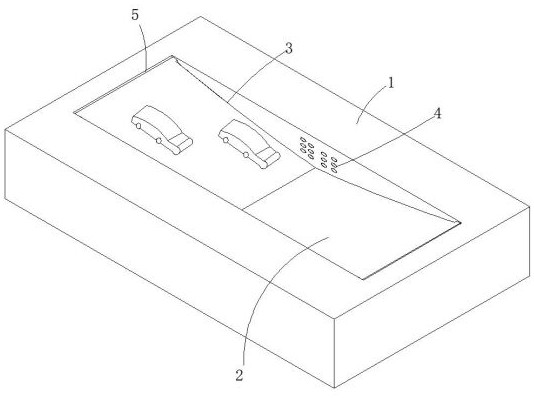

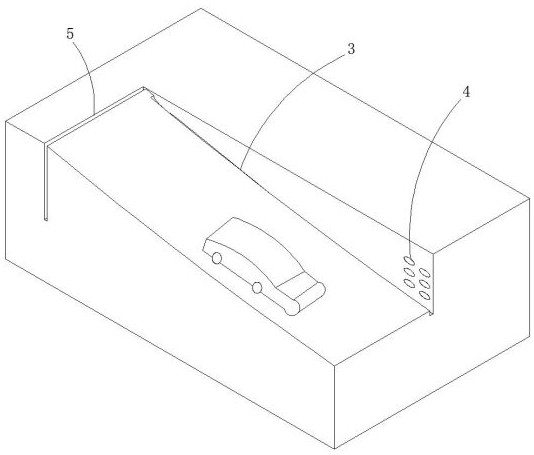

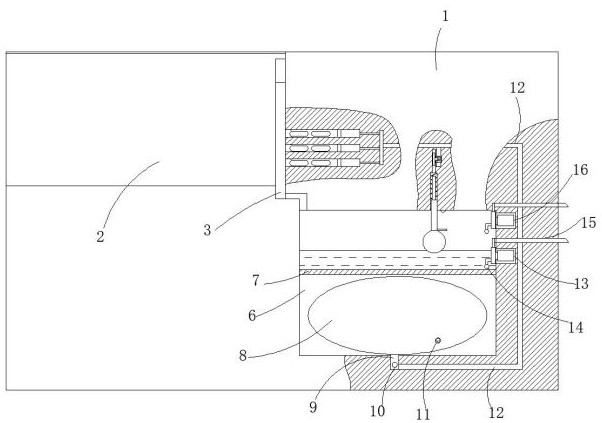

[0032] refer to Figure 1-7 , a waterproof system of an urban tunnel structure, comprising a water storage tank 6, the water storage tank 6 is provided on the roadbed 1 provided with the underground passage 2, and the water diversion grooves 3 are provided on both sides of the underground passage 2. The water tank 6 is connected, and a first suction pump 13 is fixedly connected in the water storage tank 6. A first liquid level sensor and a second liquid level sensor for controlling the start and stop of the first suction pump 13 are arranged below the first suction pump 13. The level sensor is located above the second liquid level sensor, the suction end of the first suction pump 13 is connected with a suction pipe 14, the suction pipe 14 is located in the water storage tank 6, and the outlet end of the first suction pump 13 is connected with a water outlet pipe 15, and the water outlet pipe 15 is used to connect the urban sewer pipe, the water storage tank 6 is slidably conne...

Embodiment 2

[0037] refer to Figure 1-7 , a waterproof system of an urban tunnel structure, comprising a water storage tank 6, the water storage tank 6 is provided on the roadbed 1 provided with the underground passage 2, and the water diversion grooves 3 are provided on both sides of the underground passage 2. The water tank 6 is connected, and a first suction pump 13 is fixedly connected in the water storage tank 6. A first liquid level sensor and a second liquid level sensor for controlling the start and stop of the first suction pump 13 are arranged below the first suction pump 13. The level sensor is located above the second liquid level sensor, the suction end of the first suction pump 13 is connected with a suction pipe 14, the suction pipe 14 is located in the water storage tank 6, and the outlet end of the first suction pump 13 is connected with a water outlet pipe 15, and the water outlet pipe 15 is used to connect the urban sewer pipe, the water storage tank 6 is slidably conne...

Embodiment 3

[0045] refer to Figure 1-7 , a waterproof system of an urban tunnel structure, comprising a water storage tank 6, the water storage tank 6 is provided on the roadbed 1 provided with the underground passage 2, and the water diversion grooves 3 are provided on both sides of the underground passage 2. The water tank 6 is connected, and a first suction pump 13 is fixedly connected in the water storage tank 6. A first liquid level sensor and a second liquid level sensor for controlling the start and stop of the first suction pump 13 are arranged below the first suction pump 13. The level sensor is located above the second liquid level sensor, the suction end of the first suction pump 13 is connected with a suction pipe 14, the suction pipe 14 is located in the water storage tank 6, and the outlet end of the first suction pump 13 is connected with a water outlet pipe 15, and the water outlet pipe 15 is used to connect the urban sewer pipe, the water storage tank 6 is slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com