Self-control large-diameter quick-cut corrugated pipe gate valve

A rapid cut-off, bellows technology, applied in valve device, valve details, valve shell structure and other directions, can solve the problems of gate valve shaking, inconvenient buffering, reducing convenience, etc., to prevent excessive impact force, facilitate installation and connection, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

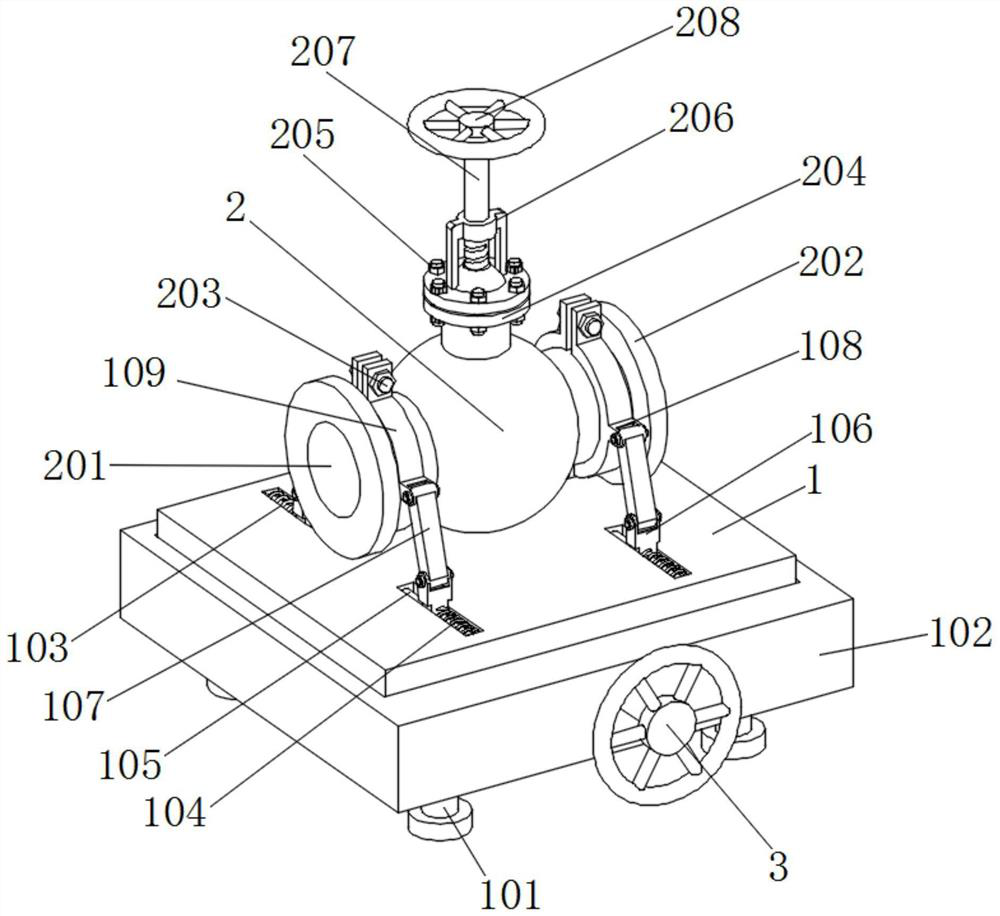

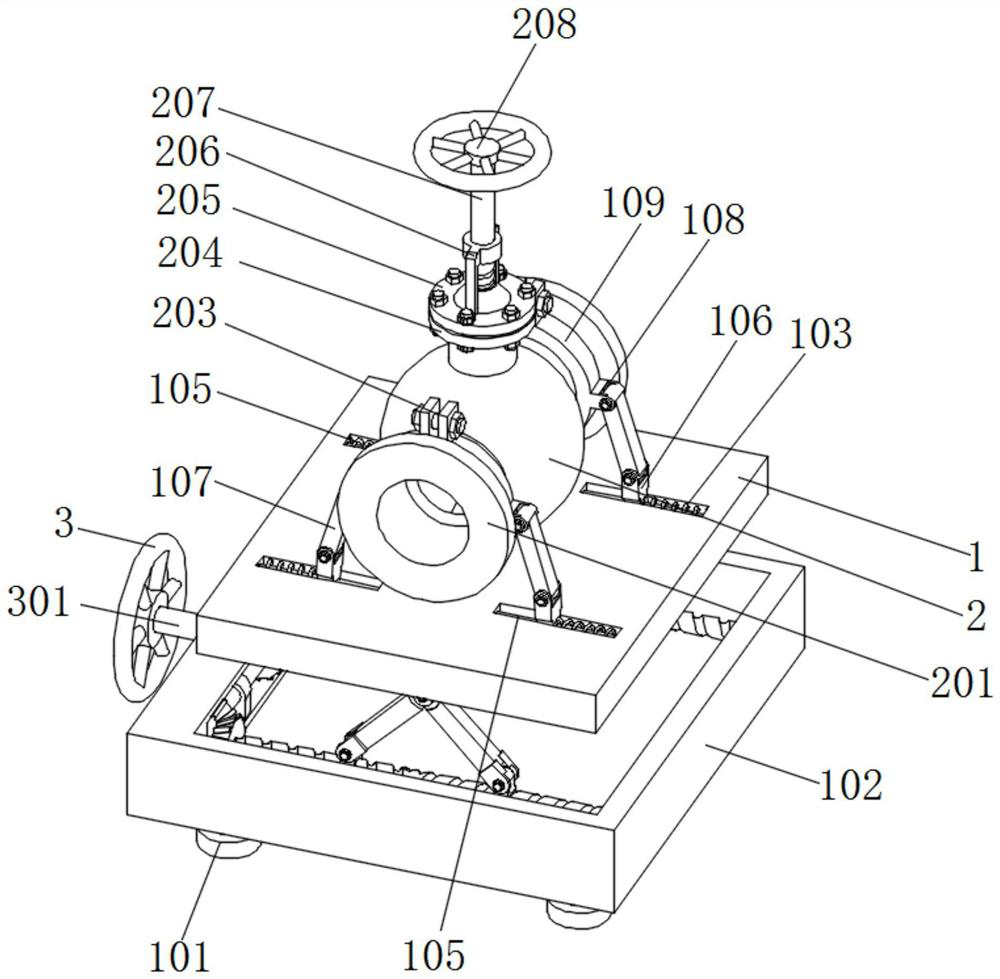

[0031] like Figure 1-7 As shown in the figure, an automatic control large-diameter quick-cut bellows gate valve proposed by the present invention includes a mounting plate 1, a gate valve body 2 and a second turntable 3. A sliding block 106 is slidably installed on the top of the mounting plate 1, and the top of the sliding block 106 is movable. A support frame 107 is installed, a gate valve body 2 is fixed on the top of the mounting plate 1, and a water inlet 201 and a water outlet 202 are fixedly installed on both sides of the gate valve body 2. The top of the support frame 107 is movably installed with the water inlet 201 and The clamping sleeve 109 matched with the water outlet 202, the valve cover 204 is fixedly installed on the top of the gate valve body 2, the first screw rod 207 is movably installed inside the valve cover 204, the flow groove 4 is arranged inside the gate valve body 2, and the mounting plate 1 A mounting seat 102 is arranged at the bottom of the mount...

Embodiment 2

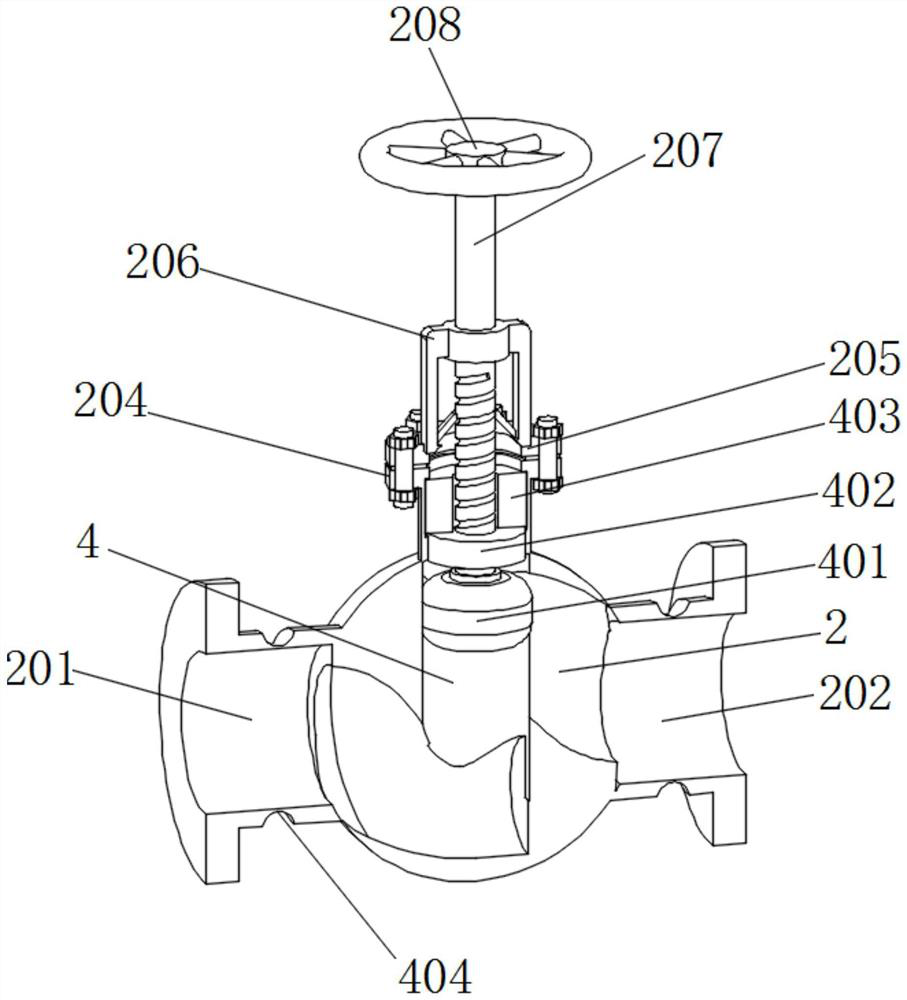

[0036] like Figure 2-7 As shown in the figure, a self-control large-diameter quick-cut bellows gate valve proposed by the present invention, compared with the first embodiment, this embodiment further includes: and the inside of the valve cover 204 is fixedly installed with a sealing gasket that cooperates with the second threaded sleeve 402 403 , the top of the valve cover 204 is fixedly installed with the fixing sleeve 206 matched with the first screw rod 207 through the flange 205 , and the support column 101 is fixedly installed at the bottom of the mounting seat 102 .

[0037] In this embodiment, the inside of the gate valve body 2 can be conveniently sealed by the gasket 403 , and the gasket 403 can conveniently seal the remaining water flow inside to prevent overflow through the top of the valve cover 204 , which can reduce the leakage during closing. The overflow causes waste, which can increase the convenience of use. The flange 205 can easily fix the fixing sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com