Solid conical spiral nozzle in spray tower

A technology of spiral nozzles and spray towers, applied in the field of solid conical spiral nozzles, can solve the problems of inconvenient satisfaction and inability to adjust the spray range, and achieve the effect of reducing required steps and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

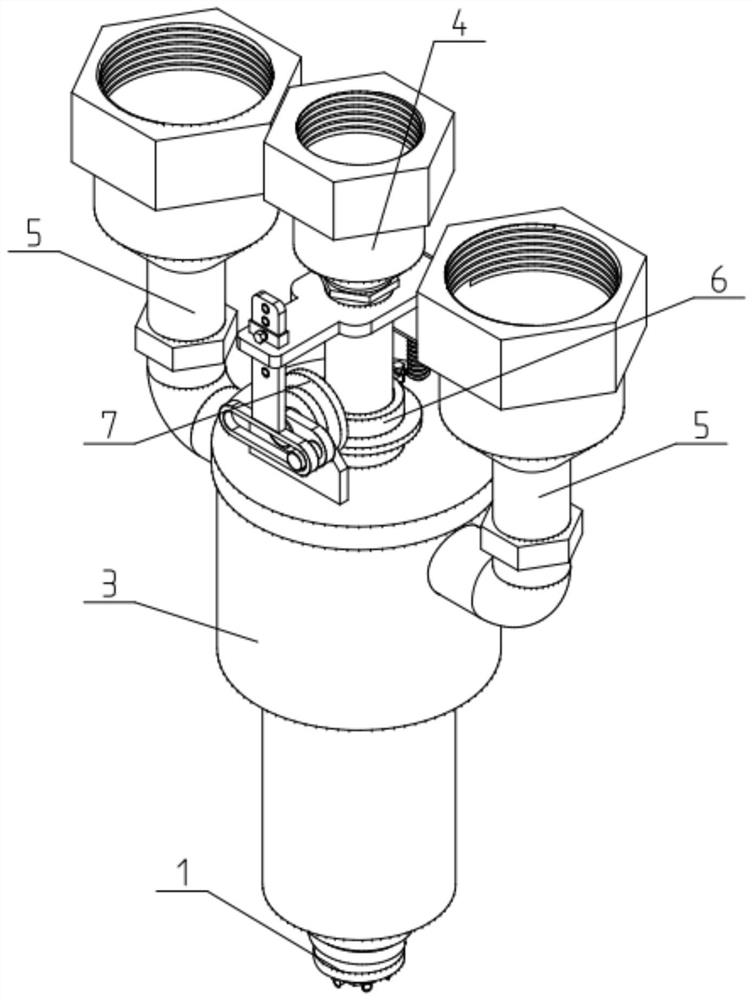

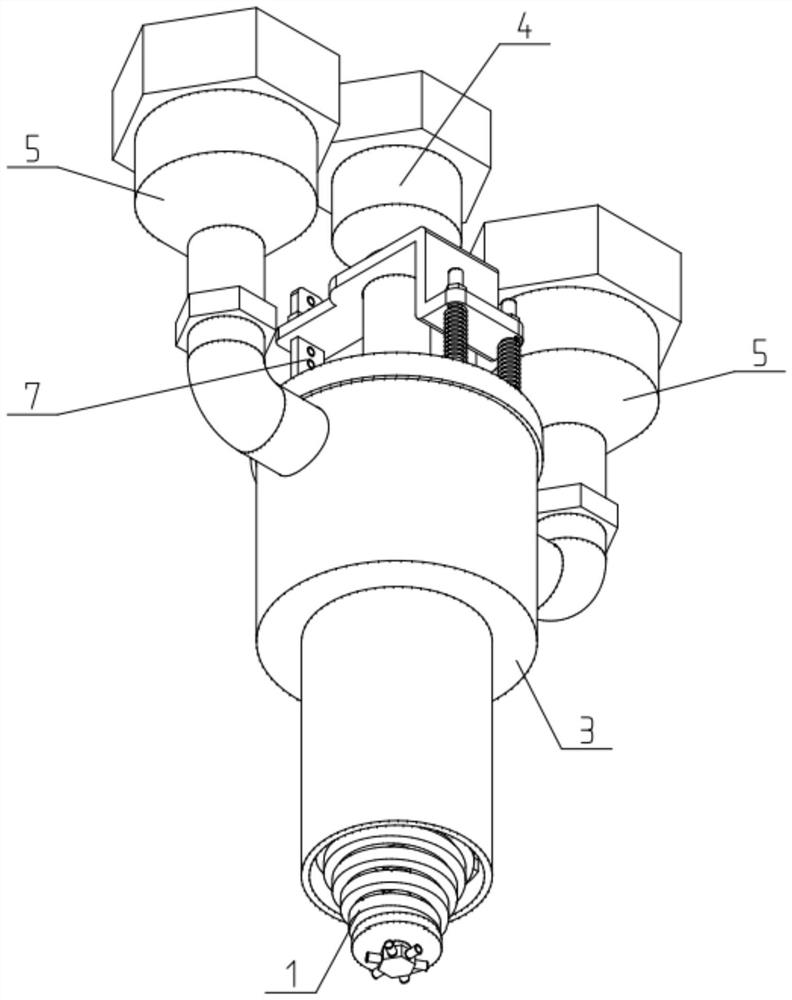

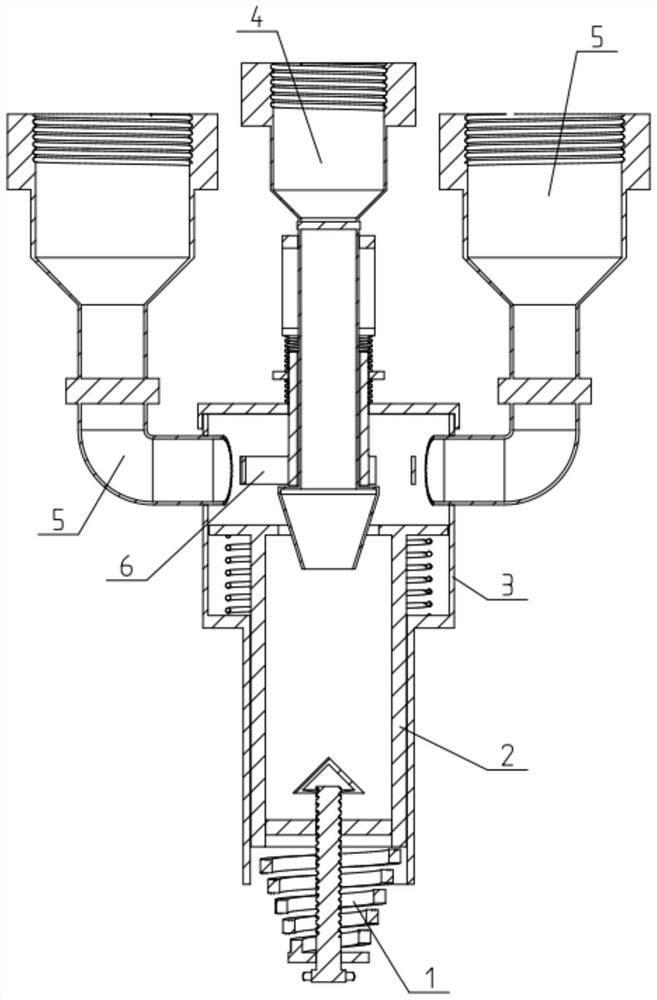

[0046] like Figure 1-3 As shown in the figure, in order to solve the problem that the length of the helical structure of the helical nozzle is fixed and its spraying range cannot be adjusted in the prior art; the present invention provides a solid conical helical nozzle in a spray tower, including a helical nozzle assembly 1, a sliding pipe Assembly 2, casing assembly 3 and water supply pipe assembly 4; the outer end of the sliding pipe assembly 2 is equipped with a spiral nozzle assembly 1 to spray multiple spray layered interfaces; the inner end of the sliding pipe assembly 2 is slidably fitted on the Inside the casing assembly 3, to protect the spiral nozzle assembly 1 through the casing assembly 3; the water supply pipe assembly 4 is installed on the casing assembly 3, and is matched with the inner end of the sliding pipe assembly 2 to drive the sliding pipe The assembly 2 slides inside the casing assembly 3, and the length of the sliding pipe assembly 2 and the spiral no...

Embodiment 2

[0049] like Figure 4 As shown in the figure, in order to solve the problem that the distance between the nozzles of the spiral nozzle is fixed in the prior art, the spray angle cannot be adjusted, resulting in a fixed range of the formed conical spray surface; a solid cone in a spray tower provided by the present invention In the spiral nozzle, the spiral nozzle assembly 1 includes a spiral nozzle body, an opening adjustment screw, a movable rod seat and a fixed rod seat; one end of the spiral nozzle body is fixed on the outer end of the slide pipe assembly 2, and the other end of the spiral nozzle body is fixed on the On the movable rod seat; one end of the opening adjustment screw is rotated and fitted on the movable rod seat, the middle part of the opening adjustment screw is threaded on the fixed rod seat, and the fixed rod seat is fixed on the inner side of the sliding pipe assembly 2; the diameter of the spiral nozzle body is determined by the sliding pipe assembly 2 gr...

Embodiment 3

[0052] like Figure 13 , Image 6 and Figure 7 As shown in the figure, in order to solve the problem that the pipeline of the spiral nozzle is inconvenient to clean the internal impurities in the prior art; in the solid conical spiral nozzle in the spray tower provided by the present invention, the sleeve assembly 3 includes a first sleeve 301, tube cover 302, second sleeve 303 and first compression spring 304; one end of the first sleeve 301 is fixedly connected to the second sleeve 303, and the inner diameter of the first sleeve 301 is larger than the inner diameter of the second sleeve 303 , forming a stepped tube body; the other end of the first sleeve 301 is detachably connected to the tube cover 302 ; a first compression spring 304 is fixed on the inner surface of the first sleeve 301 away from the tube cover 302 , and the first compression spring 304 It is sleeved on the slide pipe assembly 2. The first sleeve 301 inside the sleeve assembly 3 and the pipe cover 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com