Method for deformation forming of metal composite foil and forming equipment

A metal composite and forming equipment technology, applied in metal processing equipment, forming tools, structural parts, etc., can solve the problems of increasing material cost, volume and weight of metal composite foil, large metal composite foil, prolonging manufacturing time, etc., and achieve high energy Effect of density, avoidance of wrinkles, good cooling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

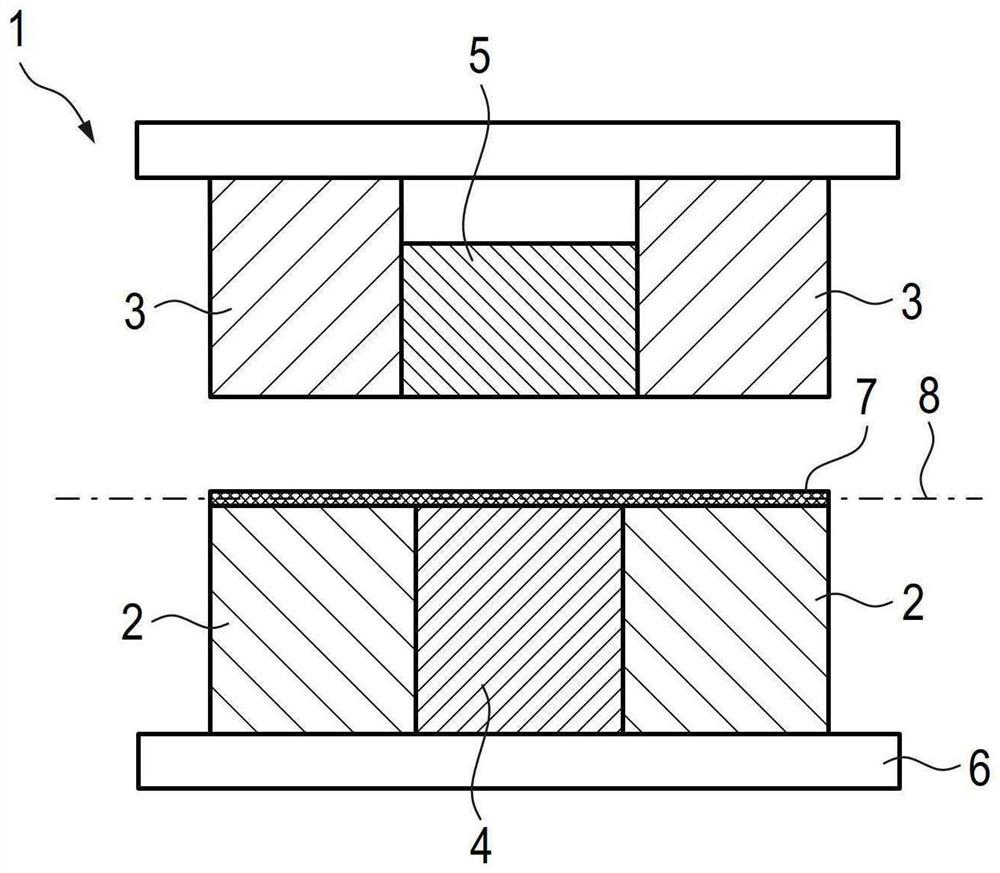

[0066] figure 1 A shaping device 1 according to the prior art is shown in a side sectional view. The forming apparatus 1 is constituted by a first sheet holder 2 , a first die 3 , a first punch 4 and a counter punch 5 . Furthermore, the forming apparatus 1 has a first drive 6 which is suitable for bringing the first sheet metal holder 2 and the first mould 3 towards each other and for fixing the metal composite foil 7 arranged in the pressing plane 8 there.

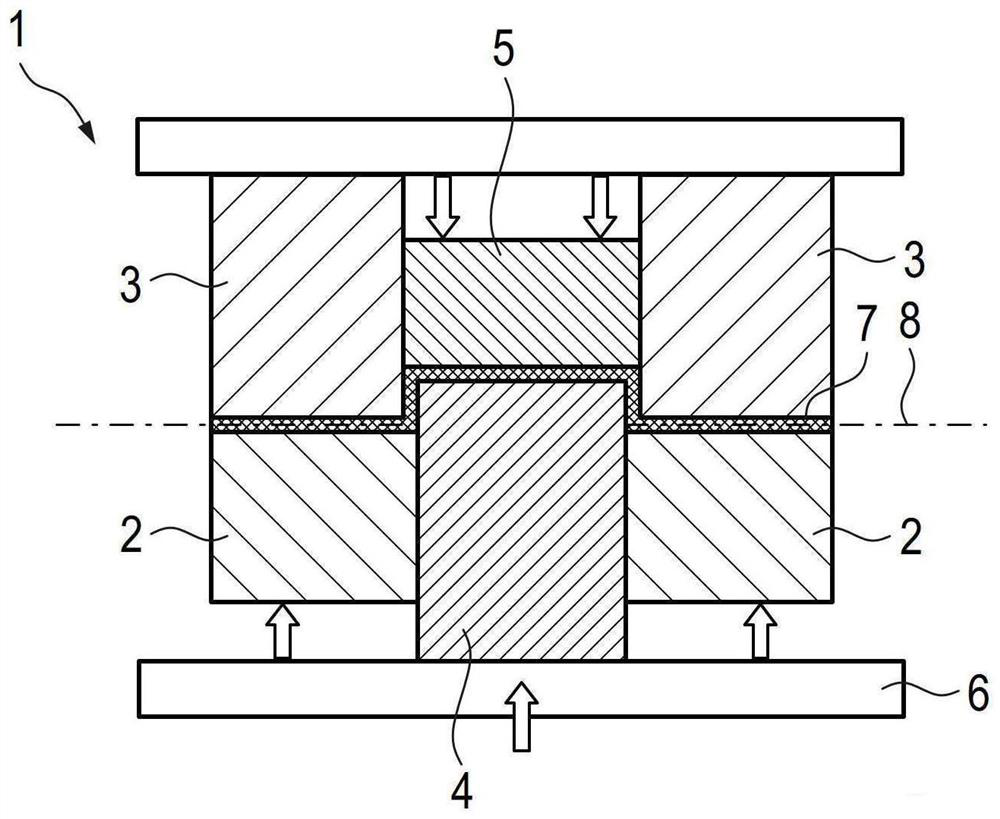

[0067] figure 2 shows according to figure 1 The forming apparatus 1 is in a state in which the metal composite foil 7 is deformed and formed in such a way that the punches 4 together with the counter punches 5 move upwards into the first die 3 in the drawing plane.

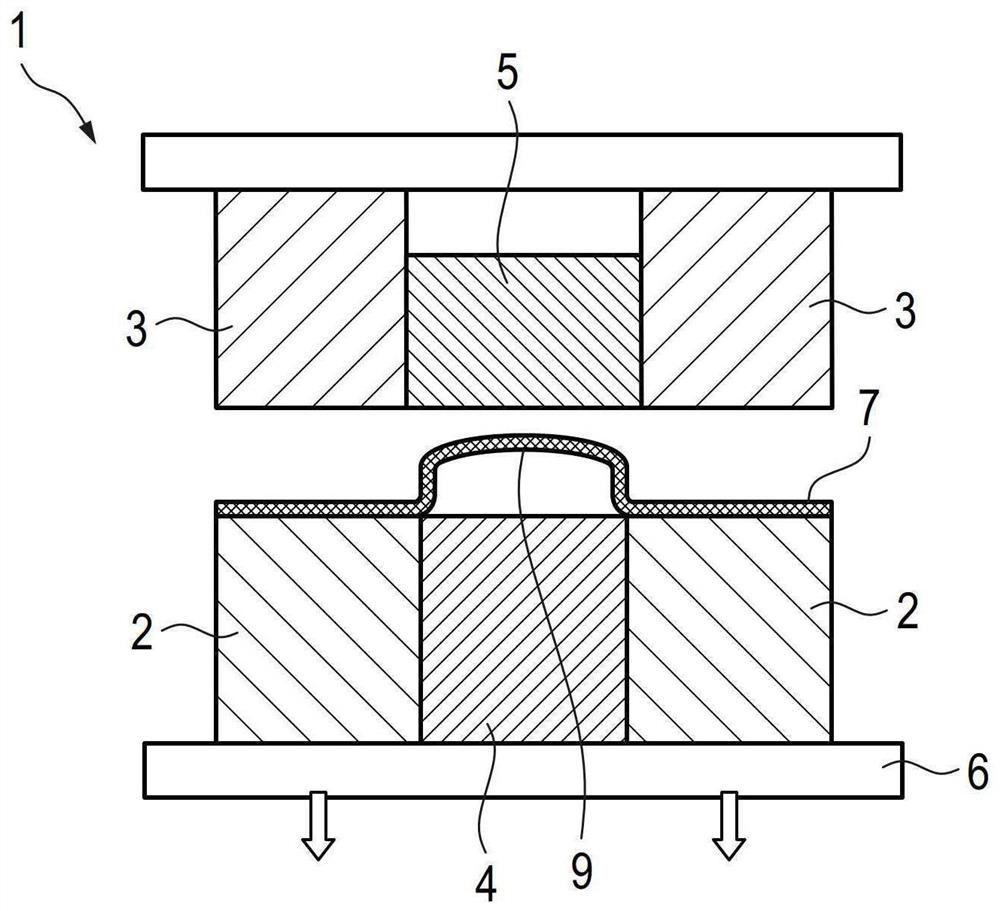

[0068] image 3 The situation is shown when the forming device 1 is opened after the deformation forming process, which means that all segments, namely the sheet holder 2, the die 3, the punch 4 and the counter punch 5, are moved back into their original...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com