Knife pouch structure

A tool holder and tool handle technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve the problems of complex connector design, increased wear of tool holders, and limited rotation space of tool handles, etc., to reduce guiding The difficulty of deviation correction, the reduction of production management costs, and the effect of facilitating fixed storage of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

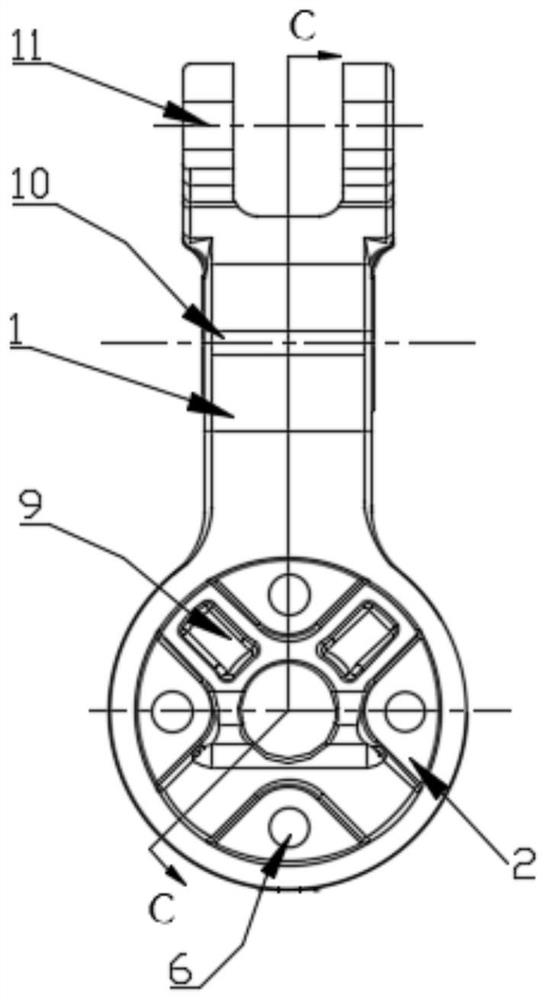

[0096] Knife cover structure, including knife cover 1 and base;

[0097] The inside of the knife sleeve 1 forms a cavity, and the cavity includes a through hole 17 and a through slot 3, and the through hole 17 communicates with the through slot 3,

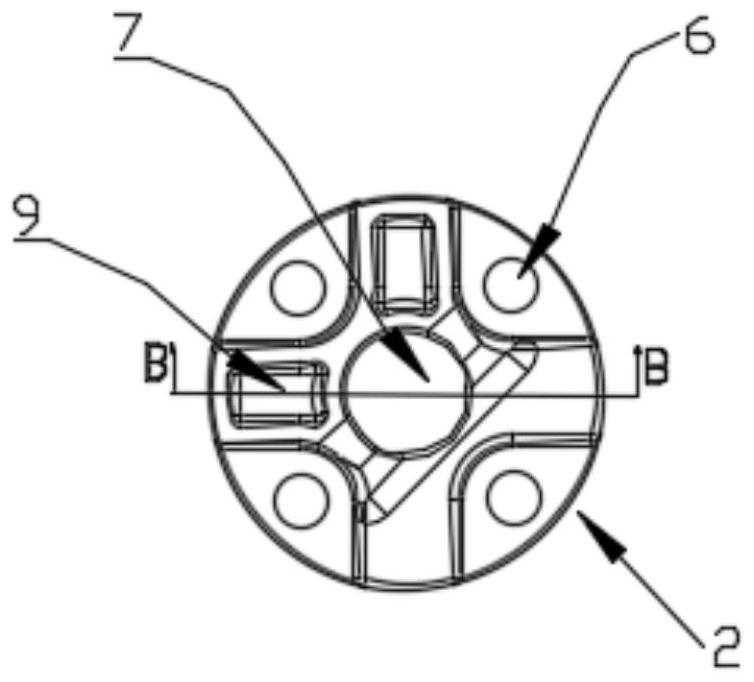

[0098] The base includes a fixed seat 2 and an elastic pressing member. A through hole 7 is formed inside the fixed seat 2. The peripheral wall of the fixed seat 2 is provided with an insertion hole 16 extending through the through hole 7. The hole 16 can be inserted into the elastic pressing member, and the base can be sleeved in the through slot 3 .

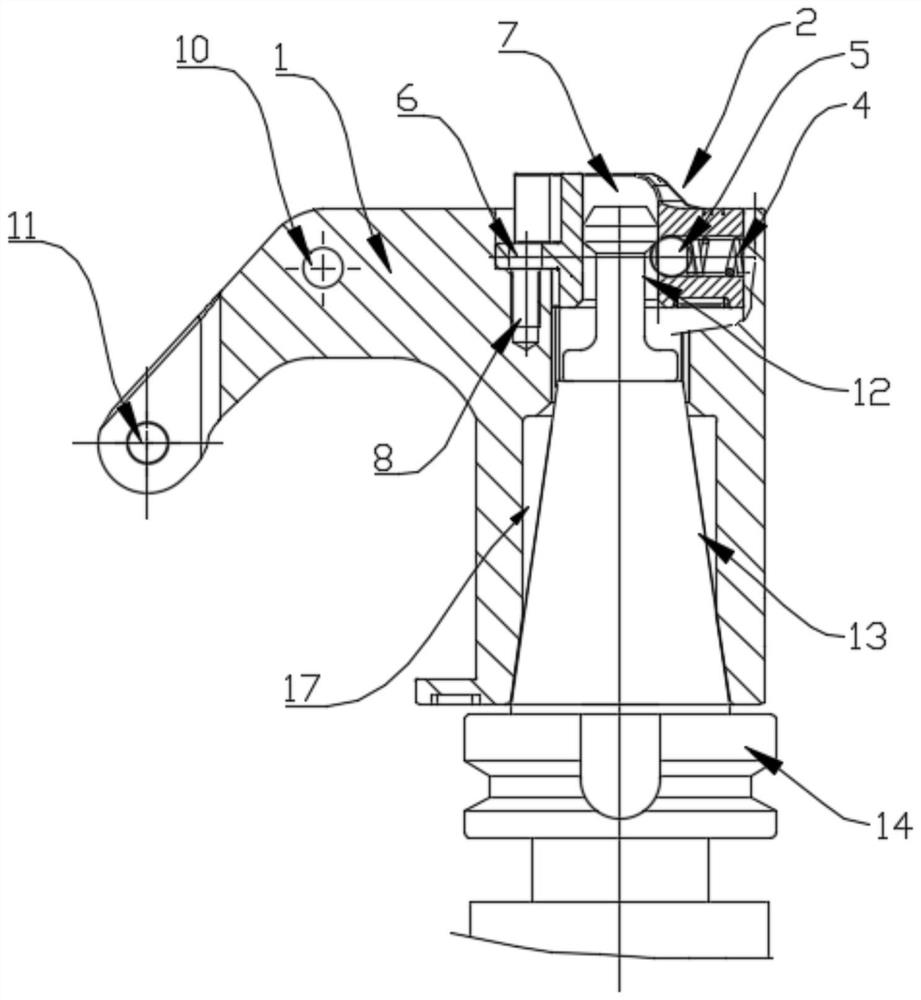

[0099] The cutter includes a cutter body 19 , a cutter base 14 , a cutter handle 13 and a pull stud 12 . The cutter body 19 , the cutter base 14 , the cutter handle 13 and the pull nail 12 are sequentially connected to form a whole. When the cutter needs to be fixed in the cutter holder 1 , the cutter The seat 14 is located outside the through hole 17, the knife handle 13 is insert...

no. 2 example

[0147] This embodiment can be applied in the same way as the first embodiment with respect to the bumps 18 and the recesses 20 and the width of the pressing surface 15 , and also includes another knife cover structure. Figure 8 , 9 , 10 and 5 and 6, including a knife sleeve 1 and a base; the inside of the knife sleeve 1 forms a cavity, and the cavity includes a through hole 17 and a through groove 3, and the through hole 17 communicates with the through groove 3, so The base includes a fixing seat 2 and an elastic pressing member. A through hole 7 is formed inside the fixing seat 2 . The fixing seat 2 is provided with an insertion hole 16 extending through the through hole 7 on the peripheral wall surrounding the through hole 7 . , the socket 16 can be used for the spring 4 and the bearing steel ball 5 to be placed in sequence.

[0148] Among them, such as Figure 8 As shown, the shape of the end of the through hole 17 away from the through-slot 3 is a shape adapted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com