Old pipe network dismounting device based on community transformation

A technology for dismantling devices and old pipes, used in water supply devices, manufacturing tools, sewer pipeline systems, etc., can solve problems such as the influence of workers' operations, thread corrosion at the pipe joints, and difficulty in disassembly, and achieve the effect of reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

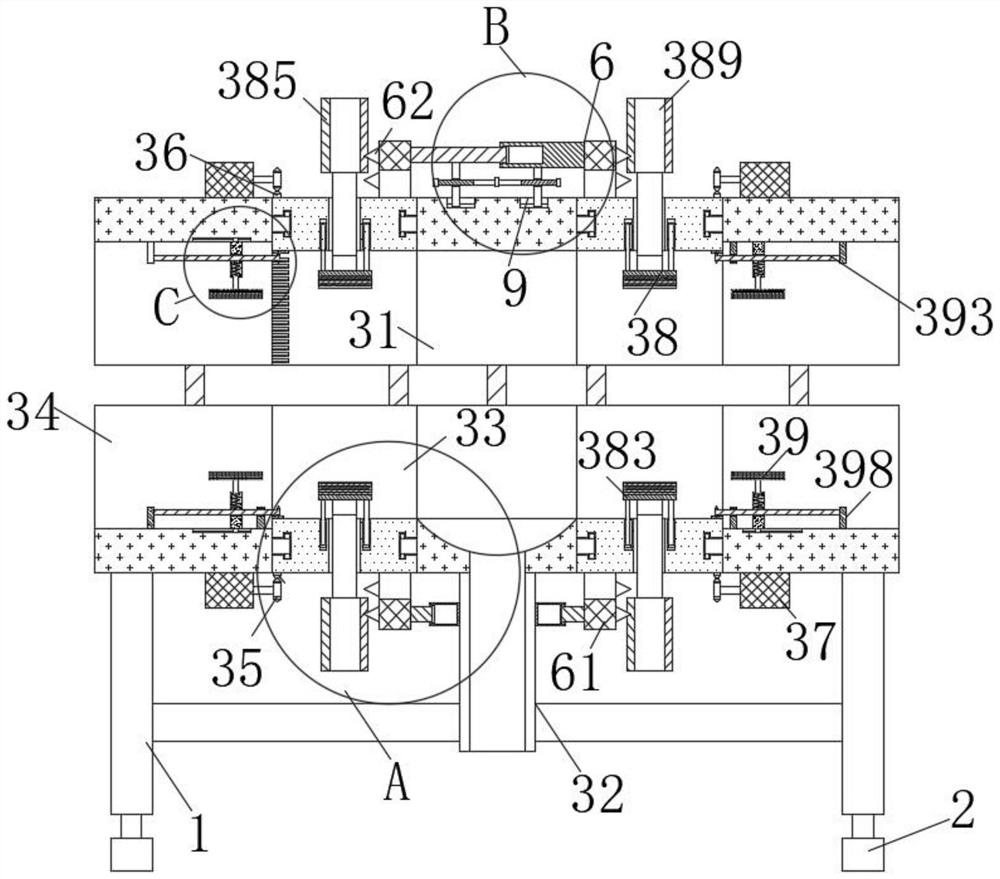

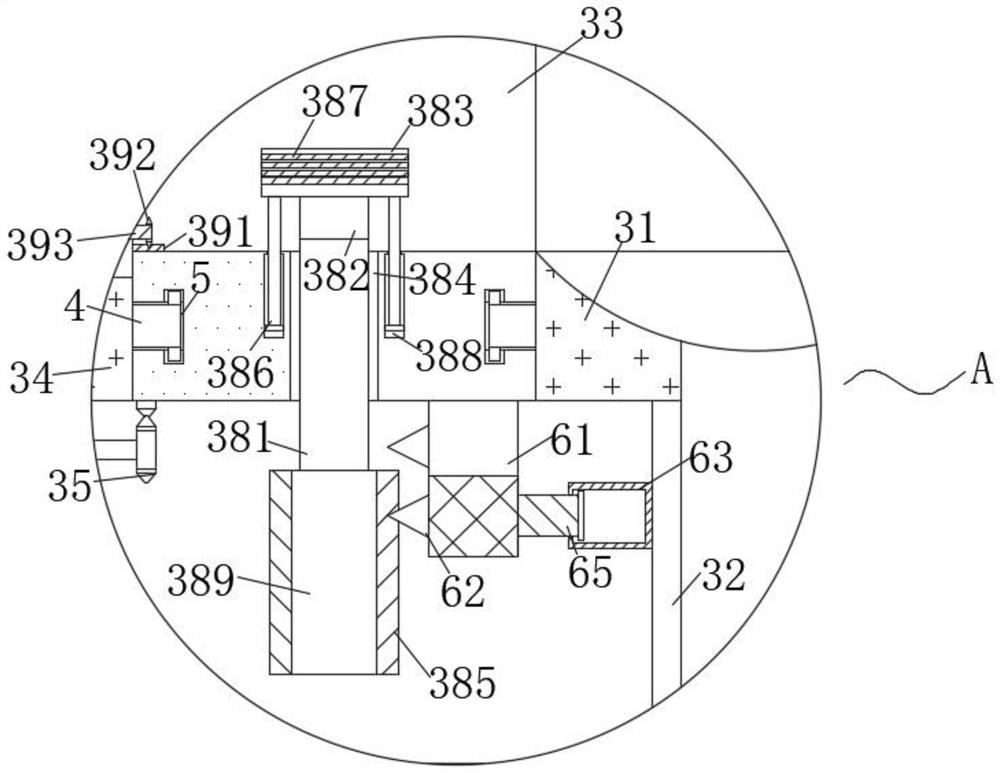

[0026] like Figure 1-6As shown in the figure, an old pipe network dismantling device based on community transformation proposed by the present invention includes a support frame 1, a universal wheel 2 and a disassembly mechanism 3. The upper outer surface of the support frame 1 is provided with two sets of disassembly mechanisms 3, and two sets of disassembly mechanisms 3 are provided. The dismantling mechanism 3 is connected by bolts, and a group of dismantling mechanisms 3 is fixedly connected with the support frame 1. The outer surface of the lower end of the support frame 1 is provided with a universal wheel 2. The dismantling mechanism 3 includes a connecting plate 31, a water outlet pipe 32, a rotating plate 33, The fixing plate 34 , the gear one 35 , the tooth one 36 , the motor 37 , the fixing component 38 and the auxiliary component 39 , the outer surfaces on both sides of the connecting plate 31 are fixedly connected with the limiting plates 4 , and the two sides of ...

Embodiment 2

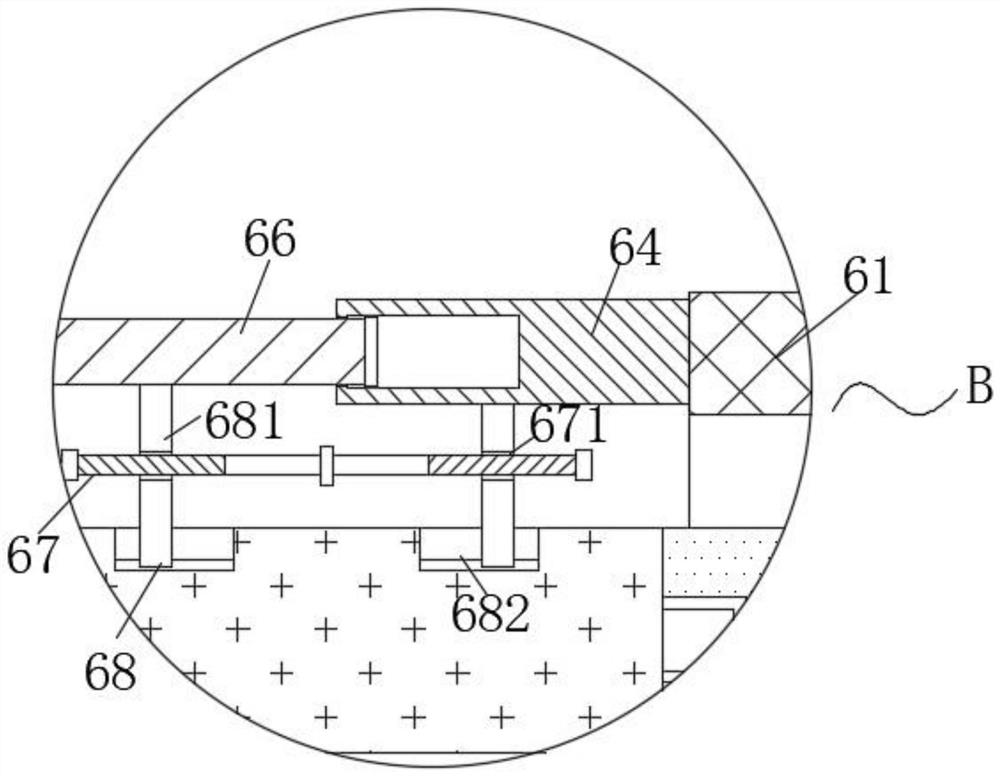

[0031] like Figure 1-6 The difference between this embodiment and Embodiment 1 is that a drive assembly 6 is provided on one side of the connecting plate 31, and the drive assembly 6 includes an arc-shaped plate 61, a second tooth 62, a fixing cylinder 1 63, a fixing cylinder 2 64, T Type rod 1 65, T-shaped rod 2 66, rotating rod 67 and slider 1 68, the outer surfaces of both sides of the water outlet pipe 32 are fixedly connected with a fixed cylinder 1 63, and the interior of the fixed cylinder 1 63 is far away from the end of the water outlet pipe 32 A T-bar 1 65 is movably connected, and a chute 1 682 is opened on the outer surface of the upper end of the upper connecting plate 31 near both sides, and the inner part of the chute 1 682 is slidably connected with a slider 1 68, and a slider 1 68 A connecting block 681 is fixedly connected to the outer surface of the upper end of the two sets of connecting blocks 681, and the outer surface of the upper end of the two groups ...

Embodiment 3

[0036] like figure 1 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that an auxiliary assembly 39 is provided inside the fixing plate 34, and the auxiliary assembly 39 includes a third tooth 391, a second gear 392, a second threaded rod 393, and a support plate 394 , movable groove 395, connecting rod 396, clamping plate 2 397, fixing block 398 and friction strip 2 399, one side of the inner surface of the fixing plate 34 is fixedly connected with a fixing block 398, and one side of the outer surface of the fixing block 398 is rotatably connected There is a second threaded rod 393, and the inner surface of the fixing plate 34 is located on one side of the fixing block 398 with a sliding groove 2 9, and the inner part of the sliding groove 9 is slidably connected with a sliding block 2 7, and the outer surface of the lower end of the sliding block 2 7 is fixedly connected There is a support plate 394, and one end of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com