Multi-channel batch small-diameter cylinder automatic printer

A cylindrical, multi-channel technology, used in typewriters, printing devices, printing, etc., can solve the problem that the production efficiency of a single machine is difficult to meet the automatic production efficiency of the production line, the efficiency of a single-channel cylindrical printer is not fast enough, and the machine occupies an area of major problems, to achieve the effect of reducing labor costs, high production efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

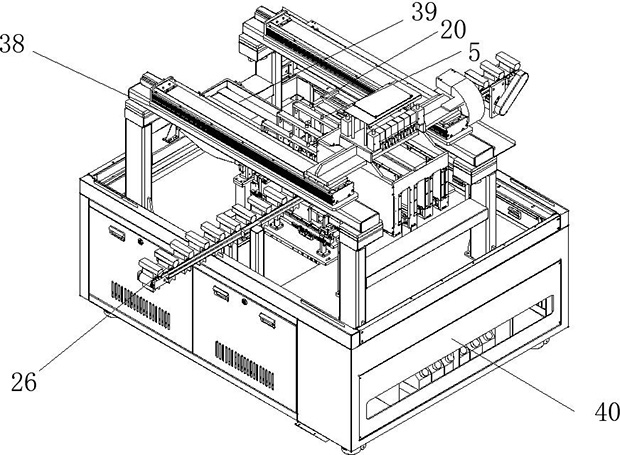

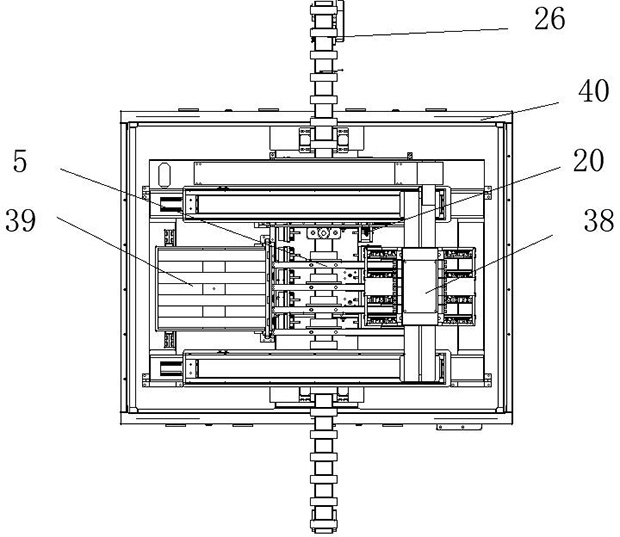

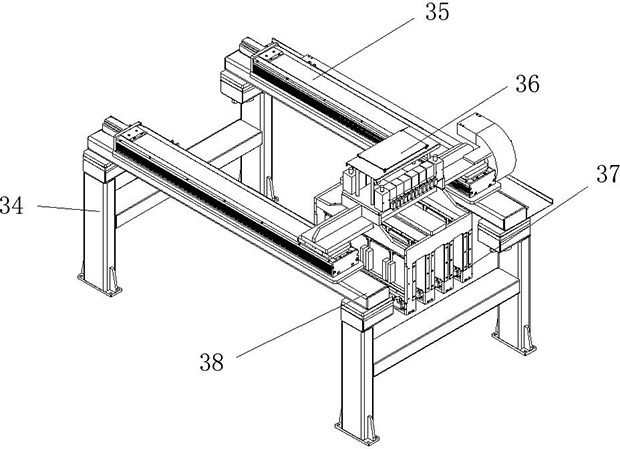

[0034] like Figure 1-9As shown, the embodiment of the present invention provides a multi-channel batch small-diameter cylinder automatic printer, including a bottom case 40, a printing mechanism 38 is provided on the upper right side of the bottom case 40, a conveying mechanism 26 is provided on the upper middle part of the bottom case 40, and the conveying mechanism 26 is provided with a primary curing mechanism 5 on the front side, a secondary curing mechanism 20 is provided on the middle and rear side of the conveying mechanism 26, and a cleaning mechanism 39 is provided on the upper left side of the bottom shell 40. To sum up, start the machine and the system self-check The status of the equipment. After the self-check is completed, the front equipment will transport the materials to the conveying mechanism 26. The conveyor belt moves four materials at a time, and transports the four materials to the primary curing mechanism 5. After the system detects that the materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com