Automatic anti-theft door production line

A technology of production line and anti-theft door, which is applied in the direction of transportation and packaging, roller table, conveyor objects, etc., can solve the problems of anti-theft door left and right swing, line stop maintenance, consumption and other problems, so as to ensure normal operation and avoid left and right swing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

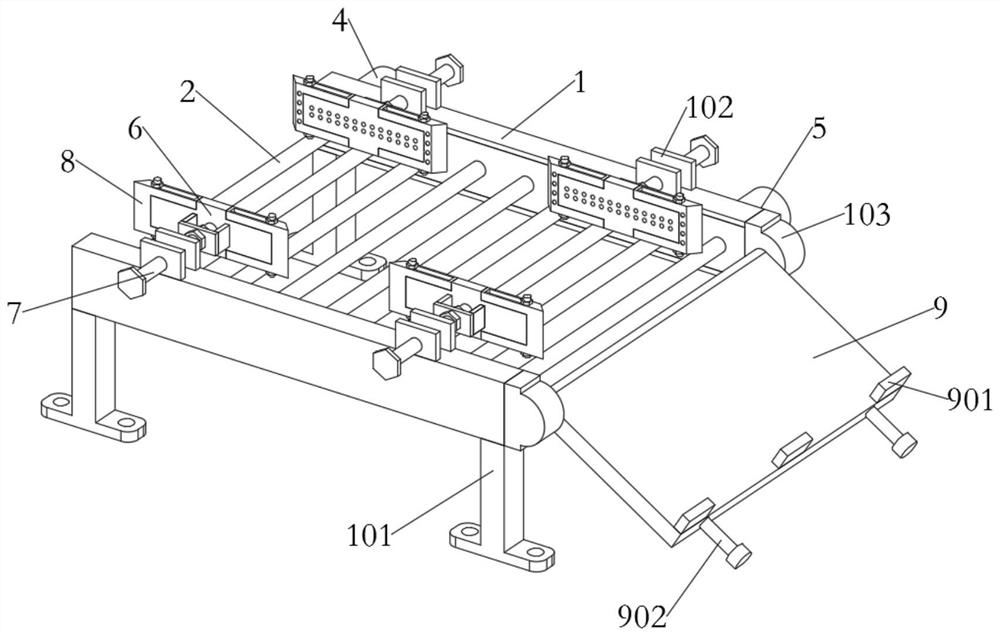

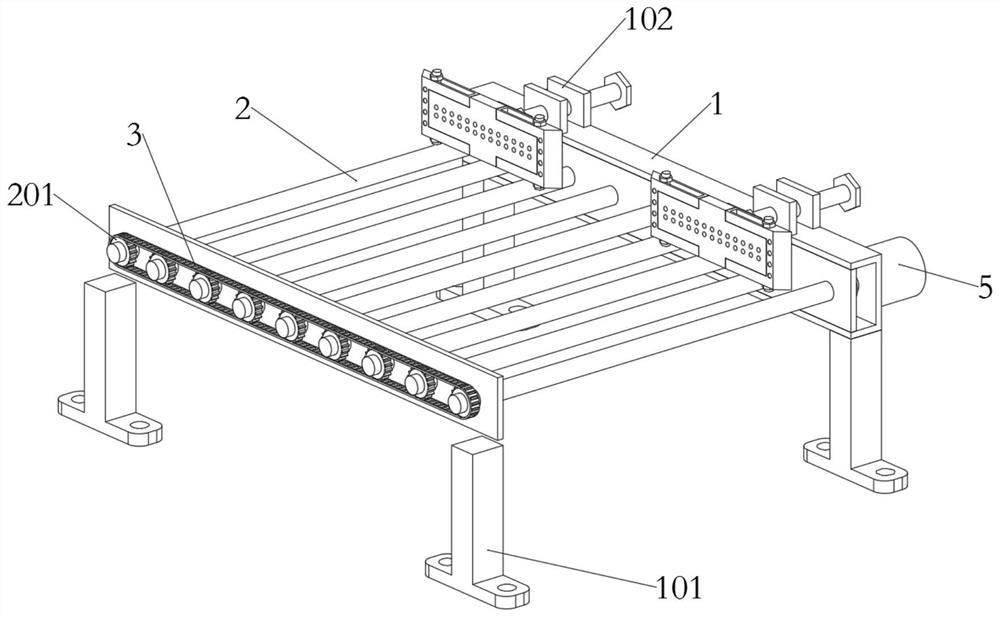

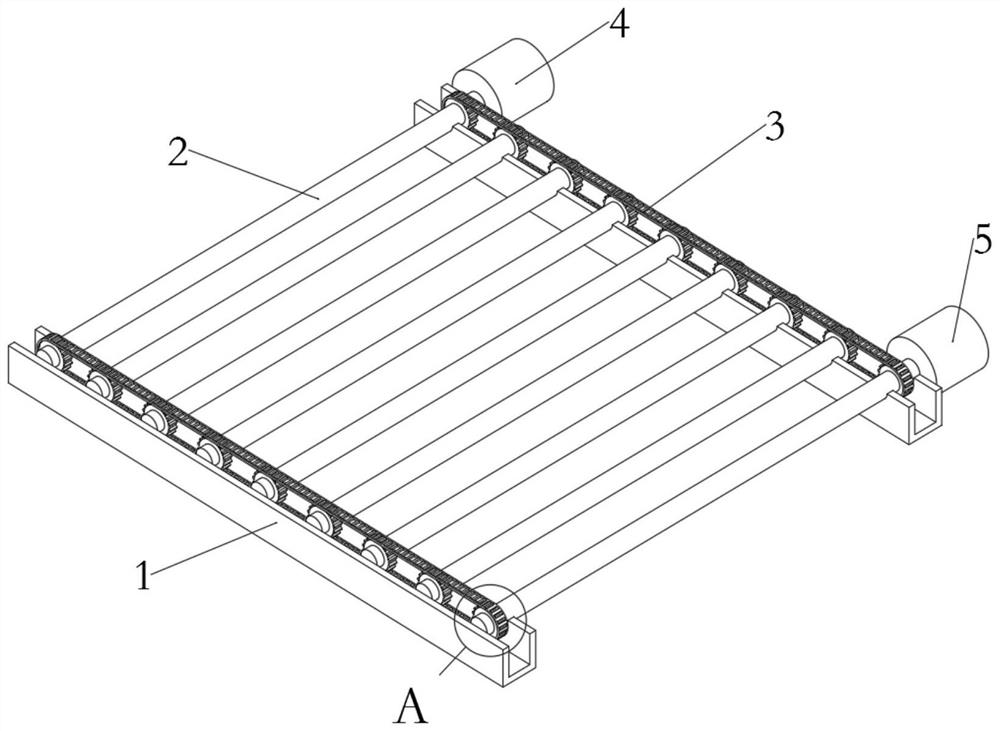

[0041] like Figure 1 to Figure 9 Show, the present invention provides an automated anti -theft door production line, including a fixed horizontal bar;

[0042] The fixed horizontal bar is provided with two groups symmetrically, and the interior of the fixed horizontal bar is a hollow structure. The lower end surface of the fixed horizontal bar is installed with support leg 101. The support leg 101 is the inverted T structure. Two fixed holes, the upper end of the fixed horizontal column 1 is evenly installed with two sets of limited board 102;

[0043] Rotating roller 2, the ends of the rotor roller 2 through the inner side plate of the fixed horizontal bar 1 and.

[0044] The first driver motor 4, the first drive motor 4 is fixed on the outer surface of the fixed horizontal bar, and the drive shaft of the first drive motor 4 is connected with the rotor 2 of the last end;

[0045] The fixed board 6, the two ends of the fixed board 6 are installed with a convex block, respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com