Automatic cable tensioning device and method

An automatic tensioning device and cable technology, which is applied in hoisting devices, tension measurement, spring mechanisms, etc., can solve problems such as cable disorder, affecting the normal use of winches, and adverse effects in the deployment and recovery process, so as to prevent and cut The effect of rope and slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

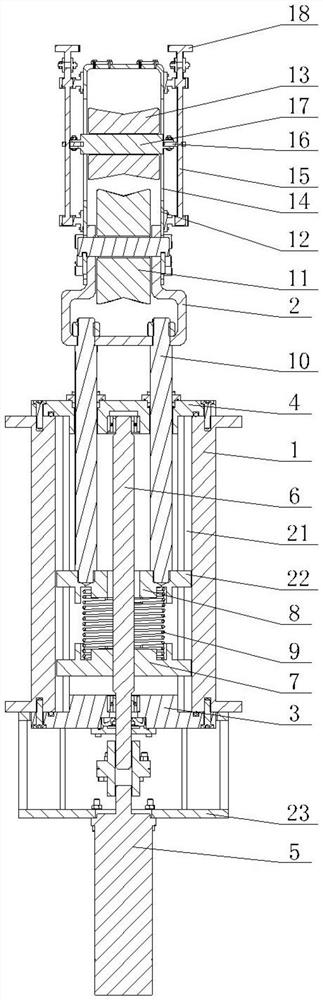

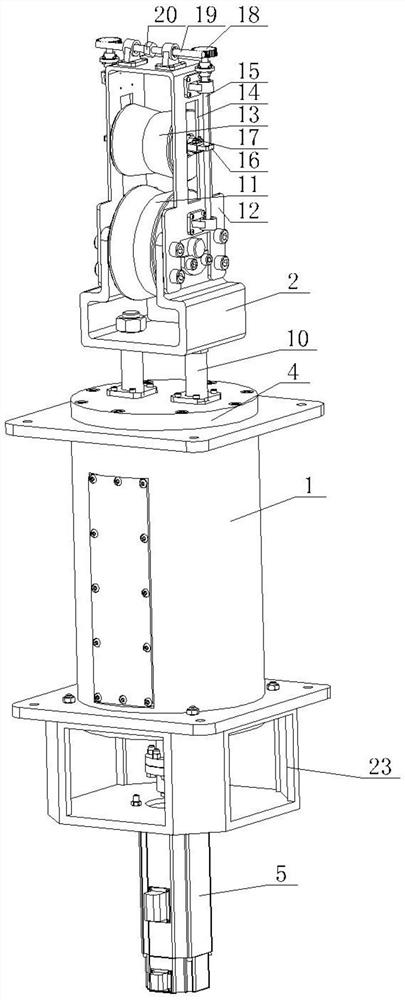

[0026] as attached figure 1 and attached figure 2 As shown, an automatic cable tensioning device includes a cylinder block 1, a mounting frame 2 and a control system. Both ends of the cylinder block 1 are open, and the two ends of the cylinder block 1 are respectively provided with a first end cover 3 and a second end cover 4. , a motor 5 is set on the first end cover 3, one end of a first lead screw 6 is set on the output shaft of the motor 5, a first sliding shoe 7 and a second sliding shoe 8 are respectively set in the cylinder block 1, and the first lead screw 6 The other end respectively passes through the first end cover 3 and the first sliding shoe 7 and is located in the cylinder block 1 . A spring 9 is set, a pressure sensor is set on the second sliding shoe 8, one end of a sliding rod 10 is set on the mounting frame 2, and the other end of the sliding rod 10 is connected to the second sliding shoe 8 through the second end cover 4, and the mounting frame 2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com