Support structure for building engineering construction and assembled dust falling equipment

A technology of construction engineering and support structure, which is applied in the direction of building structure, construction, and housing structure support, etc., can solve problems such as difficulties, increase in workers, inconvenient dust reduction, etc., and achieve the effects of difficult adjustment and installation, fast assembly, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

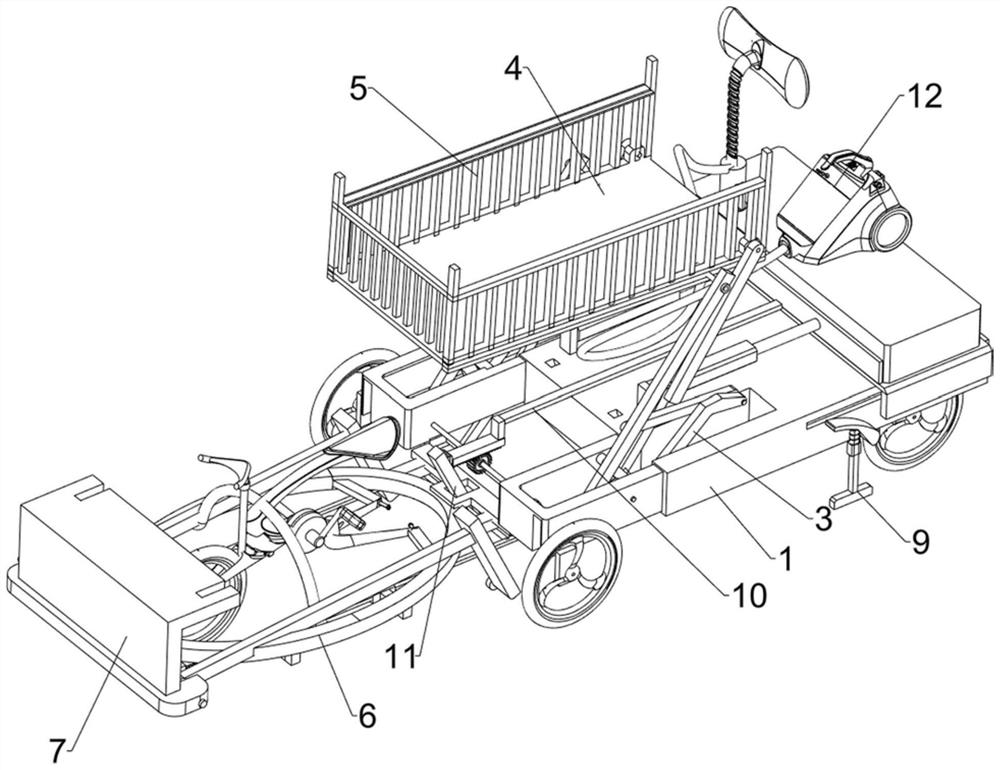

[0029] see figure 1 , figure 2 , image 3 , a support structure and assembled dust suppression equipment for construction engineering, including a pedal car 1, a horizontal plate 4 and a guardrail 5, and a first square groove 2 is symmetrically opened on the pallet at the rear of the pedal car 1, The top of the horizontal plate 4 is provided with a protective fence 5, and also includes a supporting mechanism 3, an arc frame 6 and a supporting mechanism 7. The first square groove 2 of the pedal bike 1 is installed at the position to lift the horizontal plate 4. The supporting mechanism 3, the upper part of the supporting mechanism 3 is hingedly connected with the rear positions of the left and right side walls of the horizontal plate 4, and the front side of the pedal bicycle 1 is provided with an arc frame 6, and the arc frame 6 is provided with a pair of horizontal plates 4. To the support mechanism 7 of the support function.

[0030] see Figure 5 , Image 6 and Figu...

Embodiment 2

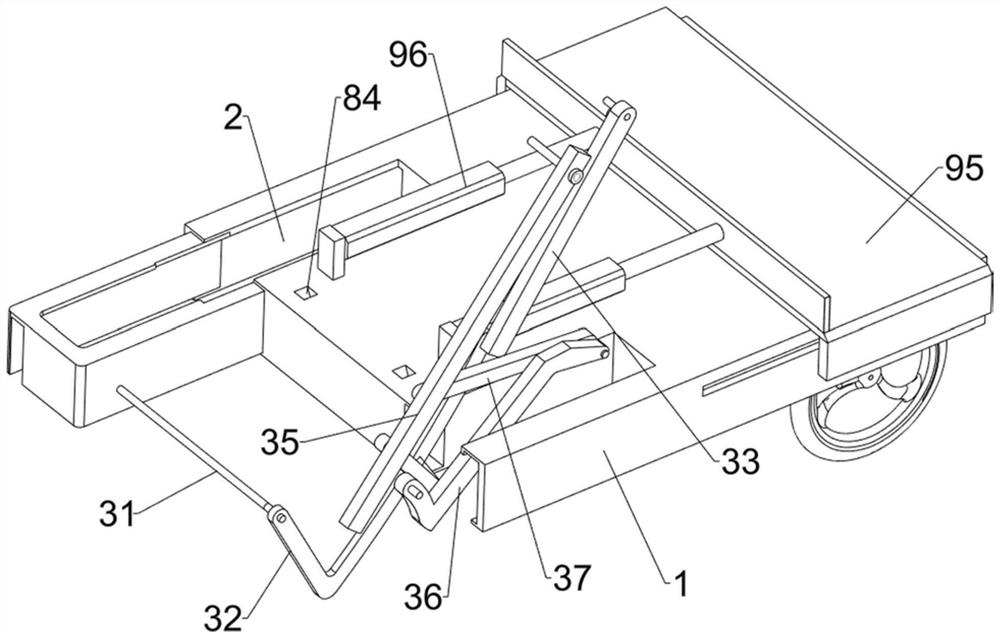

[0035] see image 3 , Figure 4 and Figure 8 , On the basis of Embodiment 1, it also includes a fixing mechanism 9. The pallet at the rear of the pedal car 1 is provided with a fixing mechanism 9 for fixing the pedal car 1. The fixing mechanism 9 includes: a guide sleeve 91, a T The bracket 92, the arc-shaped slider 93, the first elastic member 94, the sliding plate 95 and the cylinder 96, the front and rear side walls of the pallet at the rear of the pedal car 1 are provided with a guide sleeve 91 by welding, and the guide sleeve 91 The upper sliding type is provided with a T-shaped bracket 92 , the top of the T-shaped bracket 92 is provided with an arc-shaped slider 93 , and the upper part of the T-shaped bracket 92 is sleeved with a first elastic member 94 , and the first elastic member is a compression spring 94 One end of the first elastic member 94 is connected with the arc-shaped slider 93, and the other end of the first elastic member 94 is connected with the upper ...

Embodiment 3

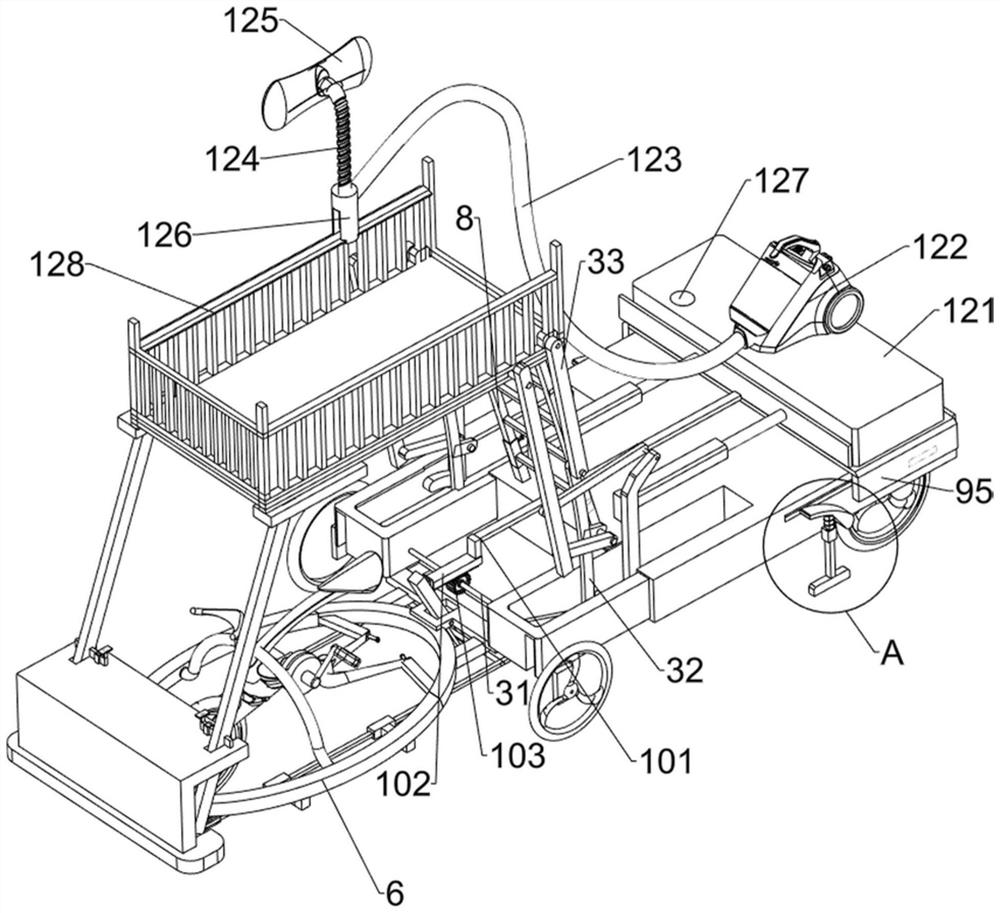

[0040] An assembled dust-reducing device includes a dust-reducing mechanism 12 and the above-mentioned support structure for construction engineering construction. A sliding plate 95 of the support structure for construction engineering is provided with a dust-reducing mechanism 12. The dust-reducing mechanism 12 includes: a water tank 121, a water pump 122, a soft The pipe 123, the folding pipe 124, the atomizing nozzle 125, the cylindrical slider 126 and the straight guide rail 128. The top of the sliding plate 95 of the support structure for construction is provided with a water tank 121 by means of screws, and a water pump 122 is provided on the water tank 121. , an interface of the water pump 122 is connected to the water tank 121 through a pipeline, one end of the hose 123 is connected to an interface of the water pump 122, the other end of the hose 123 is connected with a folding tube 124, the upper part of the folding tube 124 is connected with an atomizing nozzle 125, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com