Outward-pushing pressure-assisting type sealing ring

A sealing ring and outer ring technology, applied in flange connection, passing components, mechanical equipment, etc., can solve the problem of difficulty in resisting the external pressure of the sealing ring, and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

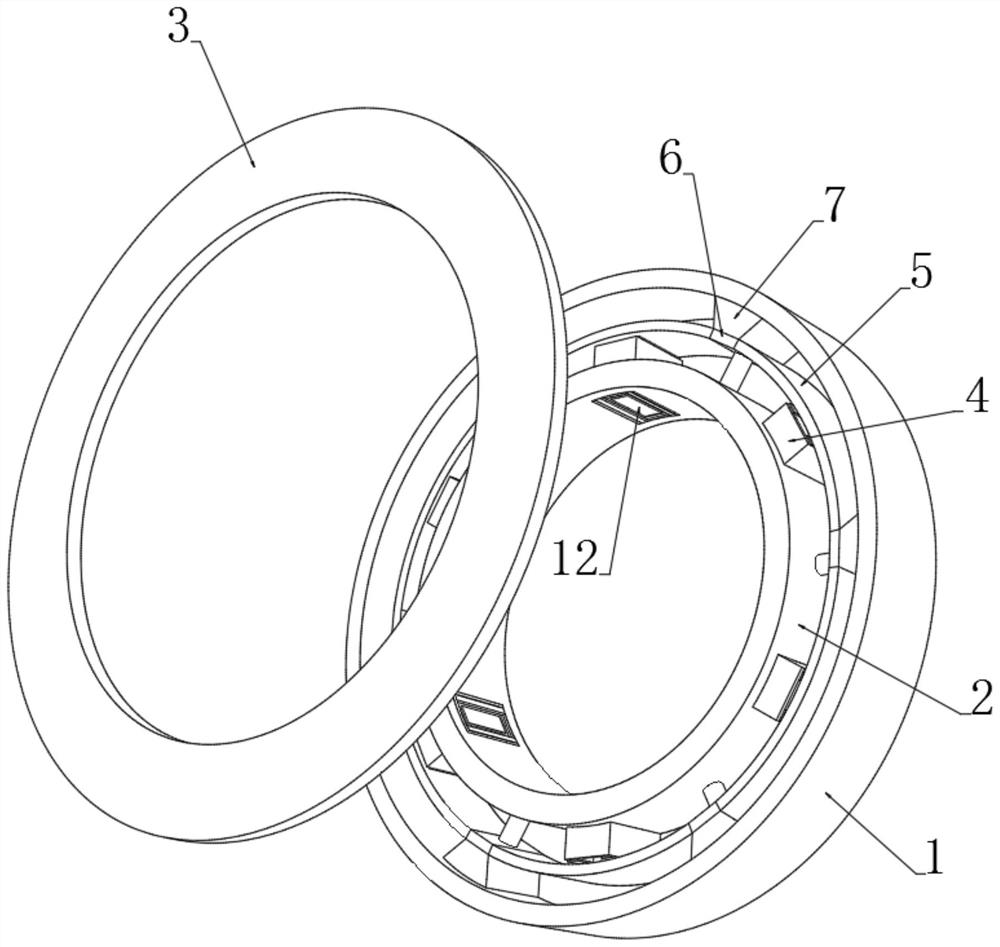

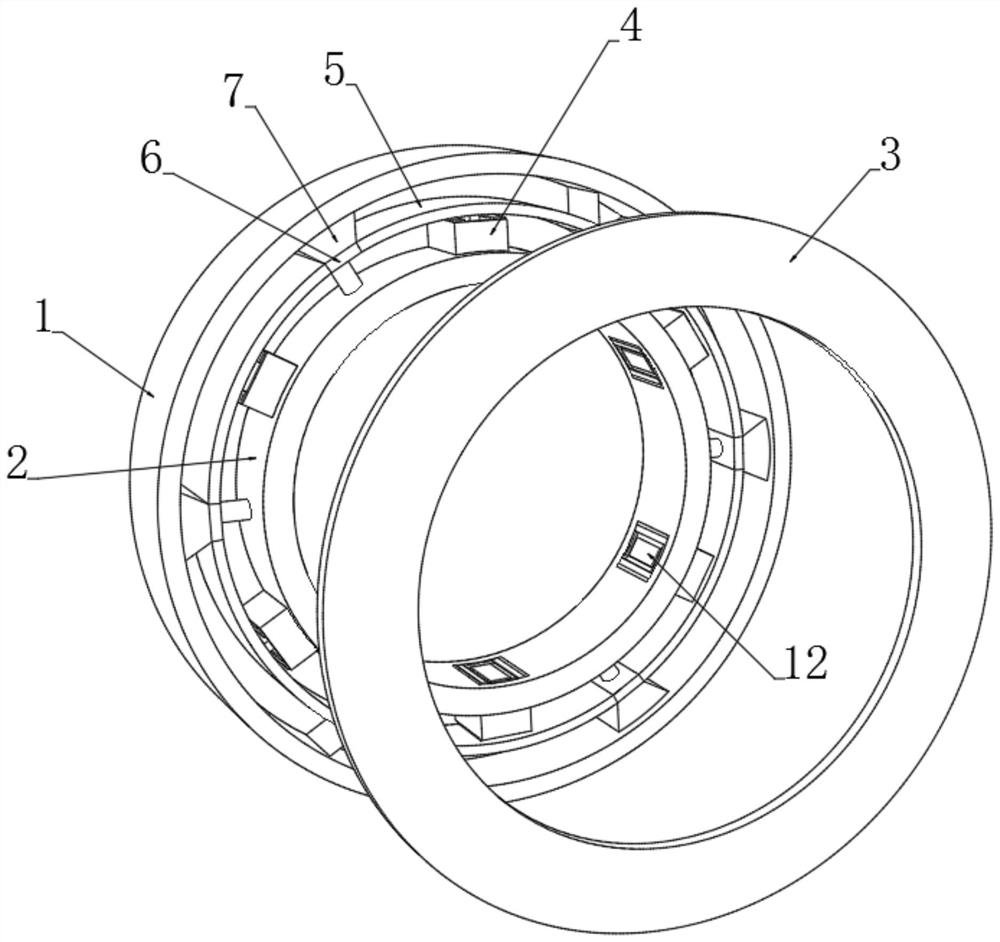

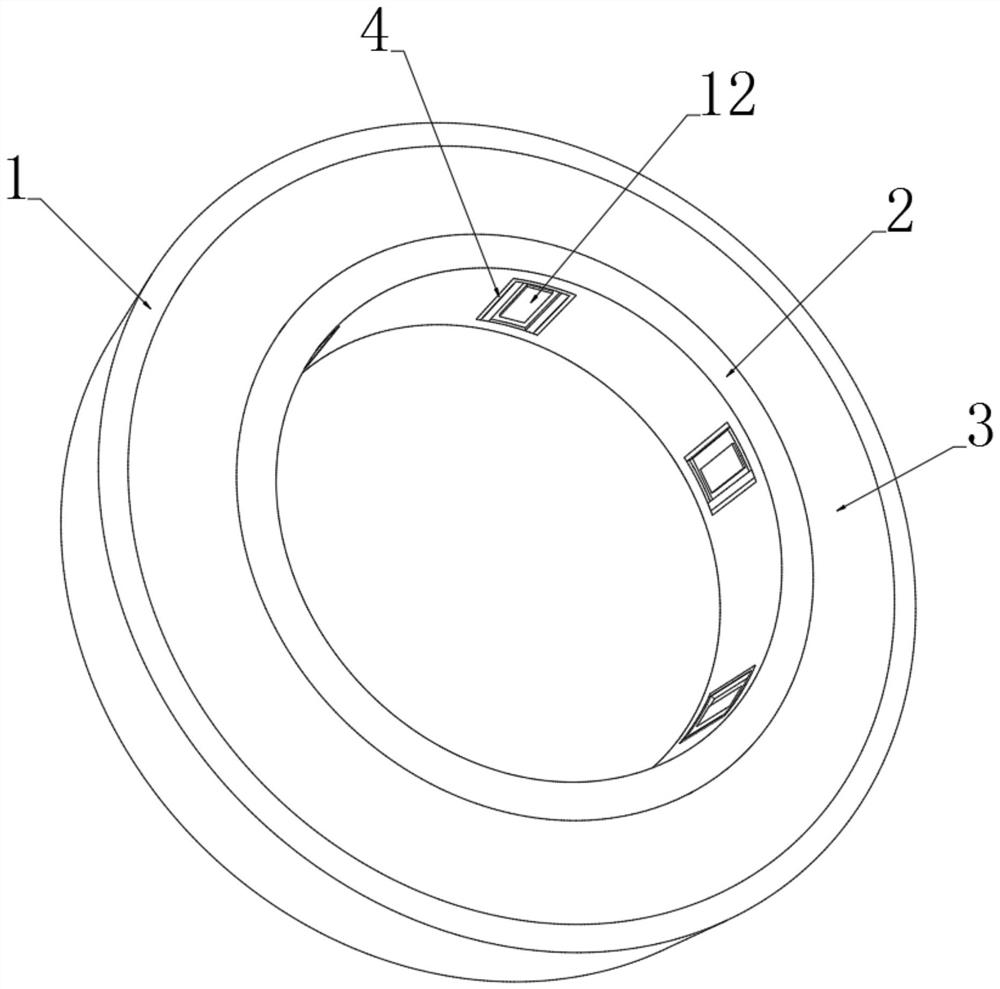

[0045] see Figure 1-3 , an external push-assisting type sealing ring, including an inner ring 2 and an outer ring 1 arranged on the inner and outer outer layers, an annular cavity is formed between the outer ring 1 and the inner ring 2, and the front and rear ends of the annular cavity are embedded with sealing rings Sheet 3, the inner and outer ends of the sealing ring sheet 3 are sealedly connected with the inner ring 2, the inner and outer walls of the outer ring 1, a plurality of trigger blocks 4 are annularly distributed on the side wall of the inner ring 2, and the inner ends of the plurality of trigger blocks 4 are connected with the inner ring 2. The inner end faces are arranged horizontally, and the outer end of the trigger block 4 penetrates the outside of the inner ring 2 and is provided with an extruding sheet 5 that is movably and sealingly connected to the inner wall of the annular cavity. It is made of rubber material, the extrusion sheet 5 is made of hard plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com