Online quality detection intelligent device for wool spinning yarn production

An intelligent device and quality technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, optical testing flaws/defects, etc., can solve problems such as blocking the line of sight, affecting detection results, and narrow detection range, etc., to achieve improvement The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

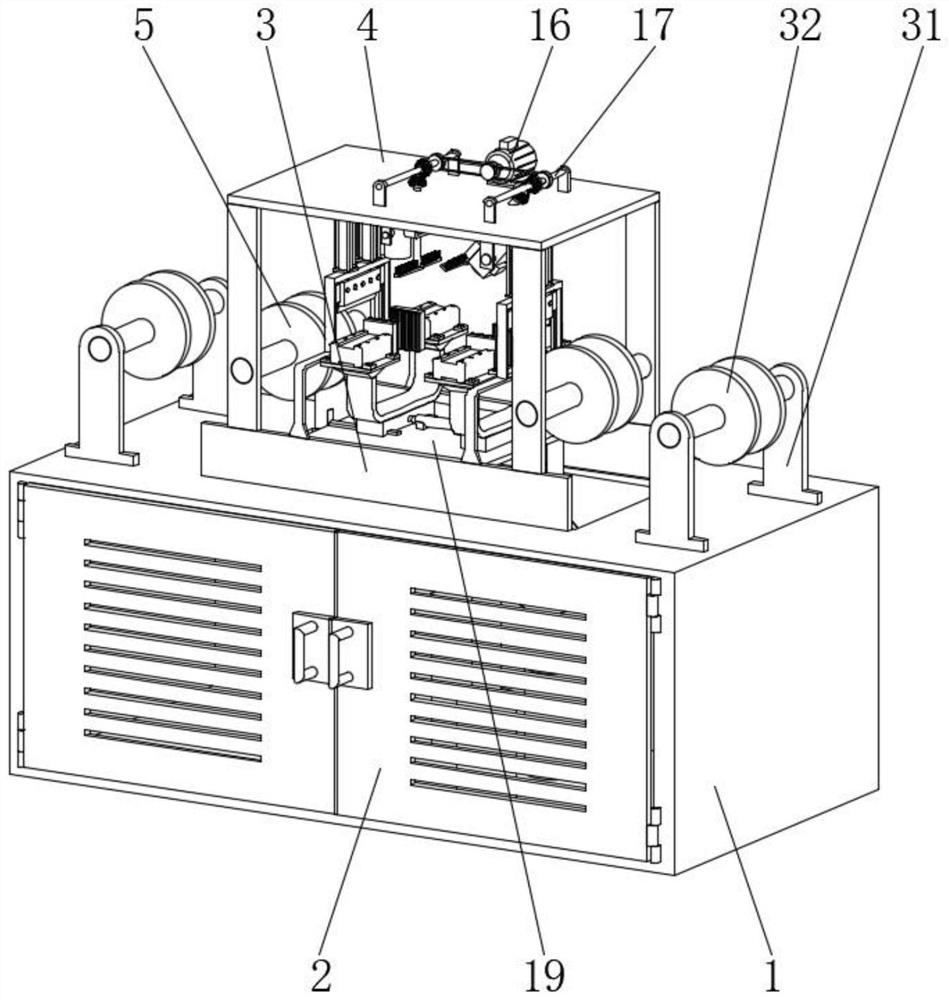

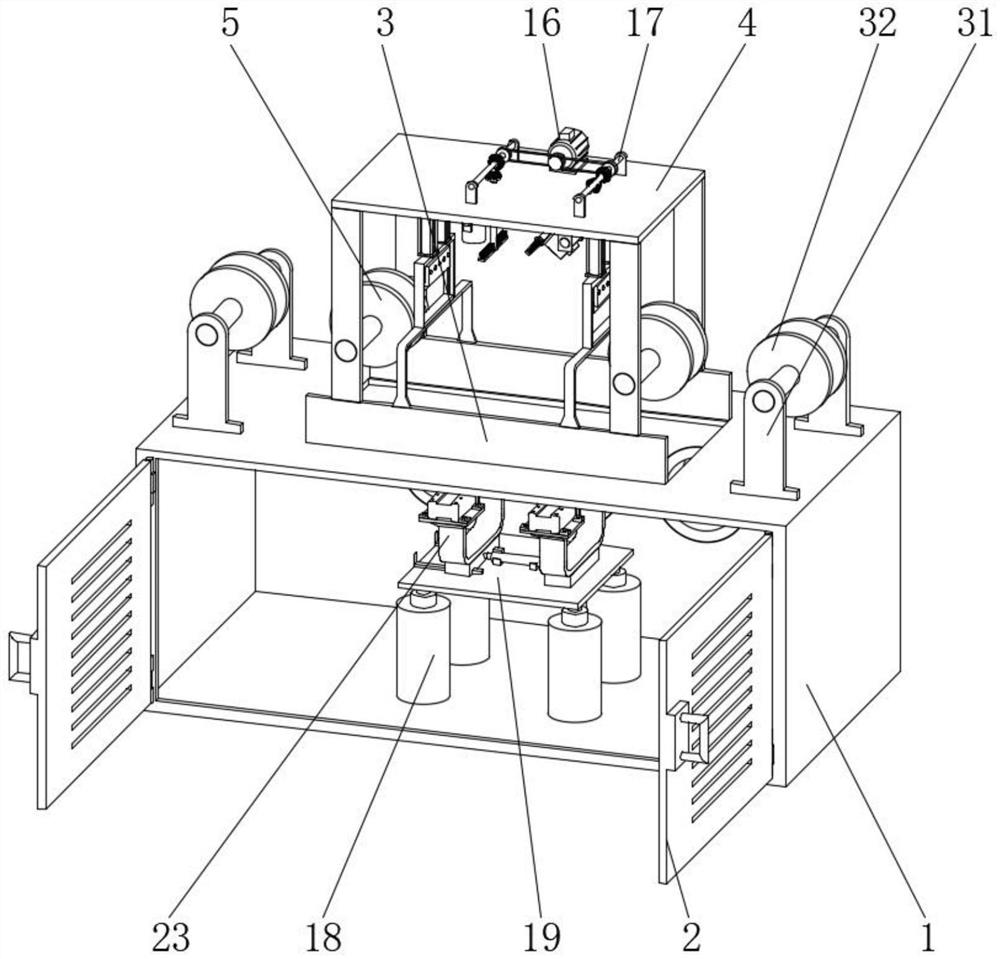

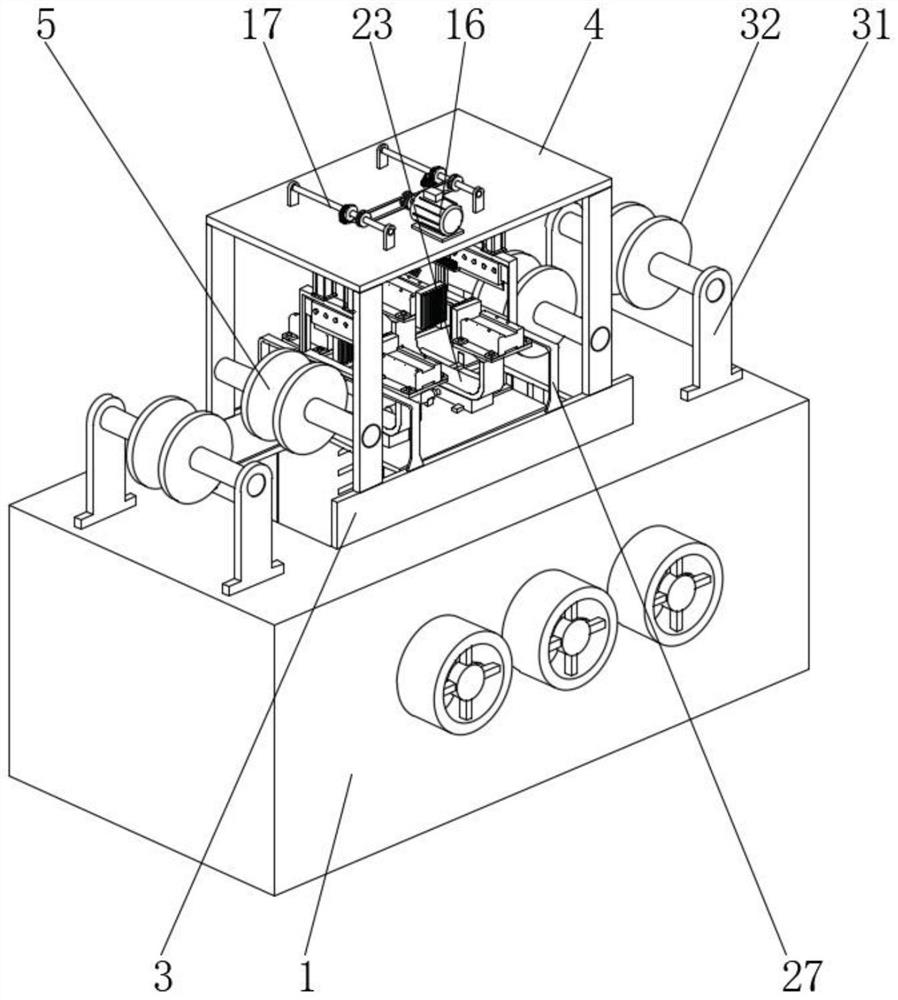

[0042] like Figure 1-Figure 9 As shown, the intelligent device for online quality detection of woolen yarn production includes a box body 1, an industrial camera body 6, an LED light source body 7, a display body 33, an alarm body 34 and a control computer 35. The front of the box body 1 is hingedly arranged There is a sealed door 2, a support frame 3 is bolted on the front and rear sides of the top of the box 1, a top seat 4 is bolted on the top of the support frame 3, and a first support wheel 5 is rotatably connected to the opposite side of the support frame 3. Industrial Both the camera body 6 and the LED light source body 7 are fixedly arranged at the bottom of the top seat 4 , the LED light source body 7 and the industrial camera body 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com