Automatic assembling device for lead storage battery polar plate of electric vehicle

A lead-acid battery and automatic assembly technology, applied in lead-acid battery, lead-acid battery construction, transportation and packaging, etc., can solve the problems of poor transportation effect, reduced installation accuracy and quality, limited precision, etc., and achieve stable installation process. Reliable, simple and easy process, high structural reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

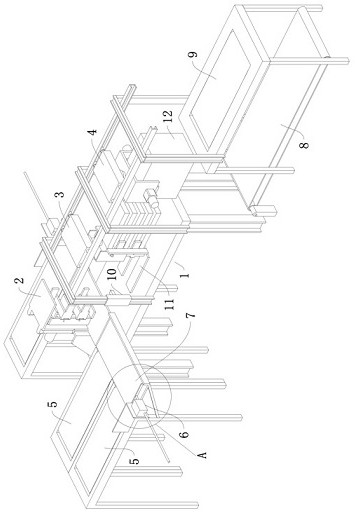

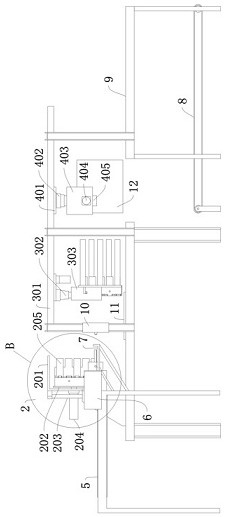

[0037] This embodiment provides an automatic assembling device for the lead-acid battery pole plate assembly of an electric vehicle, which can realize the installation of the lead-acid battery pole plate assembly, and realize the flat transportation and translational installation of the large-weight plate, which is efficient and convenient.

[0038] Specifically, as Figure 1~Figure 4 As shown, one of the structures of the automatic assembly device disclosed in this embodiment includes:

[0039] The pre-installation part 2 used for the pre-assembly of the pole plate group includes a seat plate 201 that can be raised and lowered and a pre-installation plate 205 arranged on the seat plate 201 and bent back and forth in a serpentine shape. 205a; and a blocking member 205c located at the bottom of the groove and extending along the length of the groove, and also includes an ear plate 205b hinged with the pre-installed plate 205, and the ear plate 205b and the groove bottom are fas...

Embodiment 2

[0068] This embodiment discloses an automatic assembling device for a lead-acid battery pole plate group of an electric vehicle, which is optimized and improved on the basis of Embodiment 1, and adopts a different structure of the boom assembly 303 . Specifically, the differences are as follows:

[0069] In this embodiment, the boom assembly 303 adopts another solution: the boom assembly 303 includes a boom that is turned down and extended, a support plate is provided on the boom, and the boom is flipped down to a vertical position. Fitting the pole plate group on the pre-installed plate 205, the support plate extends into the groove provided on the upper and lower surfaces of the pre-installed plate 205 and lifts the pole plate group. When this solution is adopted, a set of pallets is generally set up to just clamp the pole plate group, and the pole plate group can also be directly sent to the battery slot of the battery case 12 to complete the pole plate group during the lif...

Embodiment 3

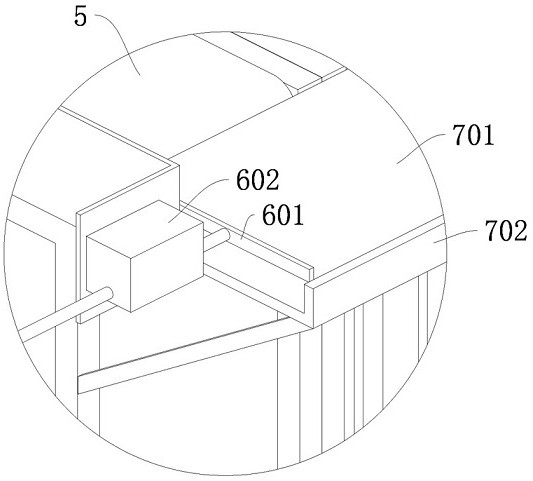

[0076] This embodiment discloses an automatic assembly device for the lead-acid battery pole plate group of an electric vehicle, which is optimized and improved on the basis of Embodiment 1, and a structure for conveying the pre-installed plate 205 is added, which can realize the assembly of the pre-installed plate 205. Automatic delivery and installation. Specifically, the differences are as follows:

[0077] A conveyor 5 for conveying the pre-installed board 205 is added outside the body 1 , and a gripper mechanism for clamping the pre-installed board 205 is provided above the conveyor 5 . The clamping jaw mechanism moves on a horizontal displacement track, which can move from above the conveyor 5 to above the seat plate 201 , and realizes the clamping and transfer of the pre-installed plate 205 to the seat plate 201 in the process. The gripper mechanism includes a gripper seat that moves along the displacement track. The lower part of the gripper seat is connected with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com