Corn pesticide spraying device and operation method

A technology of corn and swinging device, which is applied to the device for catching or killing insects, application, climate change adaptation, etc. It can solve the problems of pesticide residues, harm to human health, poor effect of diseases and insect pests, etc., and achieve uniform spraying and moving speed Uniform, good effect of removing pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below according to accompanying drawing and embodiment, the present invention is described in further detail:

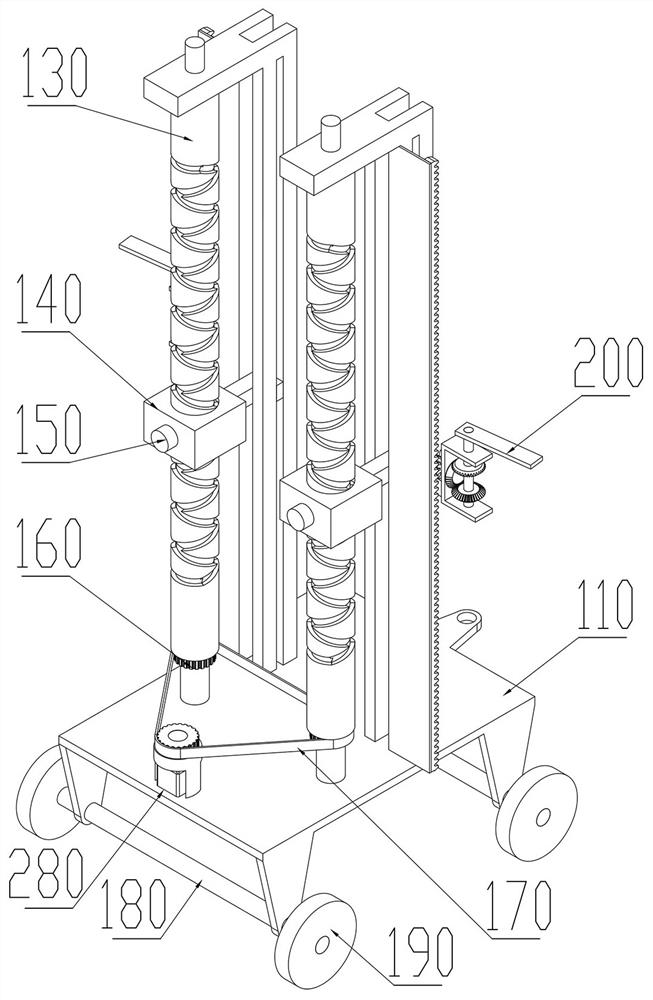

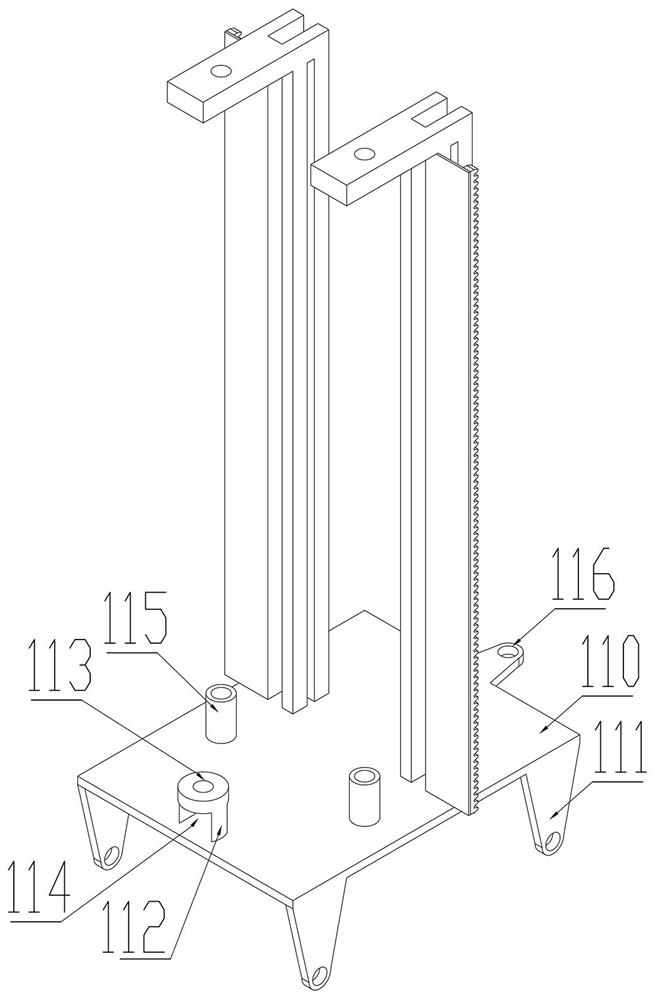

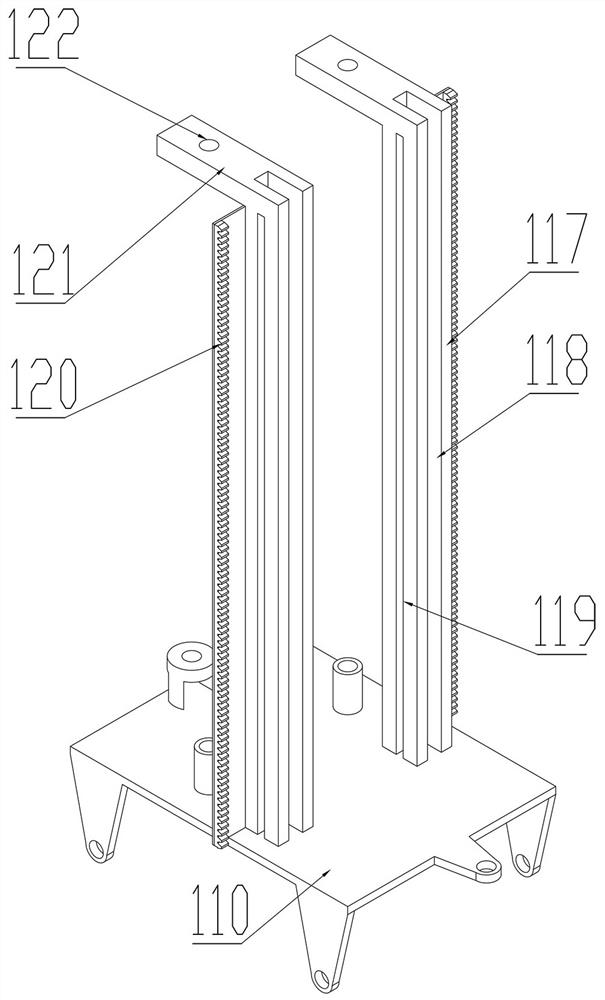

[0019] A corn spraying device and operation method, comprising a trolley 110, a rack 120, a screw shaft 130, a moving block 140, a diamond-shaped slider 150, and a swinging device 200. The swinging device 200 includes an arcuate seat 210 and a half-bevel gear 220. The lower part of the trolley 110 is evenly distributed with four bearing seats 111 , the middle of the left side of the trolley 110 has a shaft seat 112 , the middle of the shaft seat 112 has a shaft seat hole 113 , the lower part of the shaft seat 112 has a shaft seat groove 114 , and the right side of the shaft seat 112 has a shaft seat 114 . The front and rear symmetrical two bushings 115, each bushing 115 has a column 117 on the right side, each column 117 has a longitudinal slot 118 in the front and rear directions, each column 117 has a horizontal slot 119 in the left and right directions, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com