Vibration isolation device, powder collecting equipment and working method

A technology for isolating vibration and powder materials, applied in packaging, transportation and packaging, tank trucks, etc., to achieve good collection effect and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

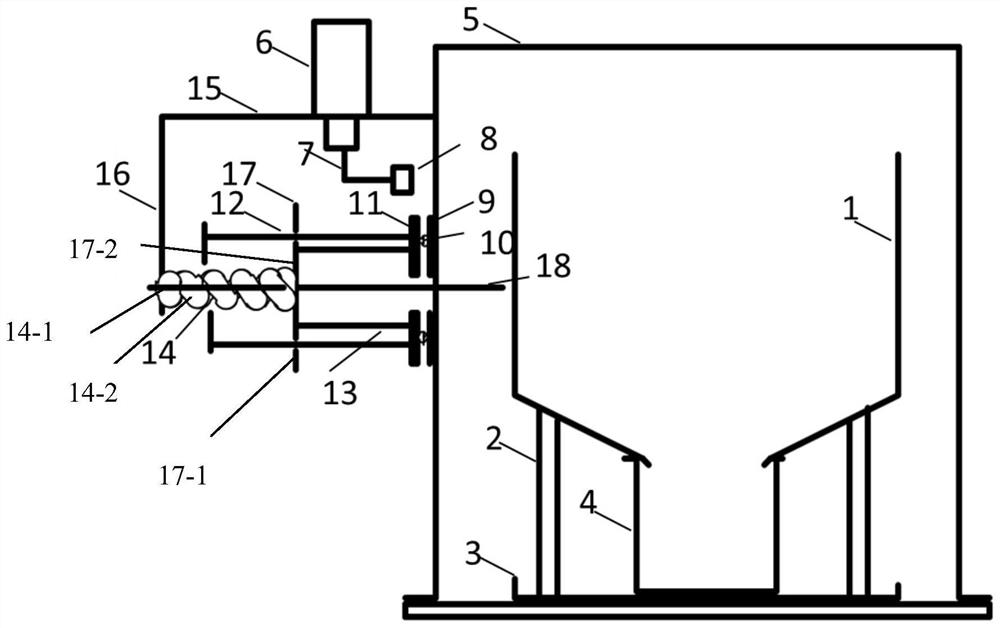

[0034] A vibration isolation device, comprising a drive mechanism, a sealing mechanism and a vibration mechanism assembled outside the reaction chamber 5, wherein:

[0035] The driving mechanism includes a fixedly installed motor 6, an L-shaped swing arm 7 fixedly assembled on the output shaft of the motor 6, and a bearing 8 installed at the end of the L-shaped swing arm 7;

[0036] The sealing mechanism includes a flexible sleeve 13 that is sealed and assembled on the reaction chamber 5 and a sealing plate 17 that seals the other end of the flexible sleeve 13 . The flexible sleeve 13 and the sealing plate 17 will open an opening on the reaction chamber 5 . to seal;

[0037] The vibration mechanism includes a vibration rod 18 fixed on the inner side of the sealing plate 17 and an elastic component 14 fixed on the outer side of the sealing plate 17 . The vibration rod 18 passes through the flexible sleeve 13 and the reaction chamber 5 . The rear end of the opening extends into...

Embodiment 2

[0047] This example is based on the powder collecting device of Example 1.

[0048] A powder collecting device includes a reaction chamber 5, a material receiving tool 1 arranged in the reaction chamber 5, and a material receiving device located at the lower part of the receiving tool 1 and docked with the outlet of the receiving tool 1 The container 4, wherein the isolation vibration device as described in Example 1 is installed on the reaction chamber 5.

[0049] The collection method of the powder collection equipment includes the following steps:

[0050] The reaction device is placed in the receiving tool 1, the lower part is placed with a receiving container 4, the isolation vibration device vibrates the receiving tool, and the vibration frequency is 7-100 times / second, and the powder enters the receiving container through the cone mouth to realize the powder. collection.

[0051] Preferably, the lower part of the receiving tooling 1 is conical, the outlet of the recei...

Embodiment 3

[0053] On the basis of Example 2, the performance of the powder collecting equipment is verified:

[0054] The reaction device is placed in the receiving tooling 1, the receiving container is placed at the lower part of the receiving tooling 1, and the reaction chamber 5 is sealed; the reaction environment is maintained, and the receiving tooling 1 is vibrated during and after the reaction process, and the vibration frequency is 90 times. / sec; after the reaction, the powder is collected in the receiving container 4, and almost no powder remains on the receiving tool 1 and the reaction device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com