Soil body micro-disturbance deep stirring device and stirring pile construction method

A technology of deep mixing and micro-disturbance, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as the inability to effectively reduce the surrounding soil disturbance, the inability of buildings to continue to be used, and the non-compliance with micro-disturbance construction requirements, etc. , to achieve the effect of saving access and construction disturbance, enhancing soil reinforcement capacity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

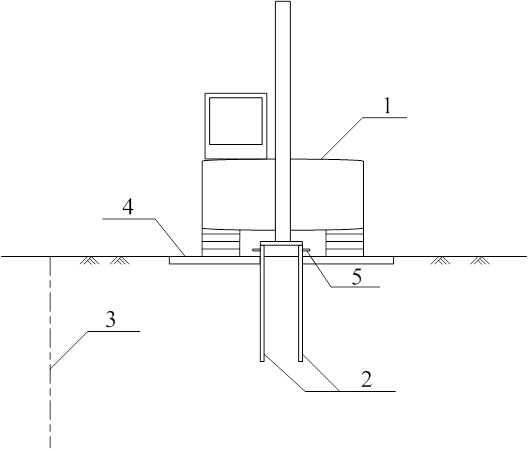

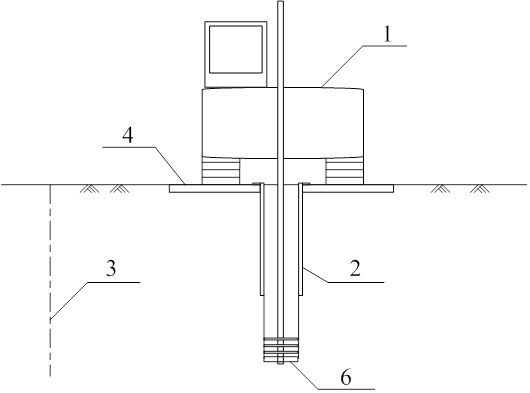

[0042] like Figure 2 to Figure 8 As shown in the figure, a soil micro-perturbation deep-level mixing device is used for the construction of deep-level stirring piles. The soil micro-perturbation deep-level stirring device includes a construction machine 1, and also includes a steel sleeve 2 and a micro-perturbation deep layer that can be connected to the construction machine 1 respectively. The overall length of the stirring drill bit 6 and the steel sleeve 2 is not more than 20% of the length of the deep mixing pile and not less than 1.5m. The construction machine 1 adopts the IMS construction method pile construction machine 1, and the construction operation modification design suitable for the spinning of the steel sleeve 2 is carried out on it. The micro-perturbation deep stirring drill bit 6 is located inside the cylinder where the steel sleeve 2 is located. The outer side of the steel sleeve 2 is provided with an external fixing member 5 that can cooperate with the exte...

Embodiment 2

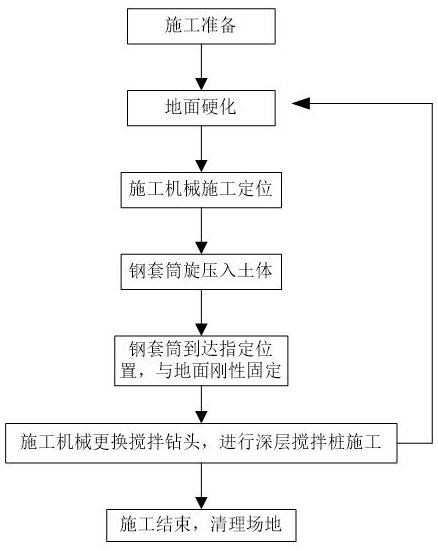

[0046] A stirring pile construction method based on the soil micro-disturbance deep stirring device according to any one of the above claims, the process steps are as follows: figure 1 shown, including the following steps:

[0047] A. Carry out ground hardening treatment on the construction area; carry out cement hardening treatment on the drilling ground required at the construction site;

[0048] B, drilling center positioning;

[0049] C. The construction machine 1 is connected with the steel sleeve 2, and the steel sleeve is spun into the soil; the construction machine 1 is adjusted at the drilling position and the construction tools of the steel sleeve 2 are installed, such as figure 2 As shown, the left side of the construction machine 1 is the existing building affected area 3;

[0050] D. When the steel sleeve 2 reaches the designated position, the external fixing device 4 is connected through the external fixing member to complete the fixing of the steel sleeve 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com