Hydraulic valve with long service life

A hydraulic valve with a long service life technology, applied in the field of hydraulic valves, can solve the problems of reducing the service life of hydraulic valves, achieve the effect of increasing service life, reducing water hammer effect, and ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

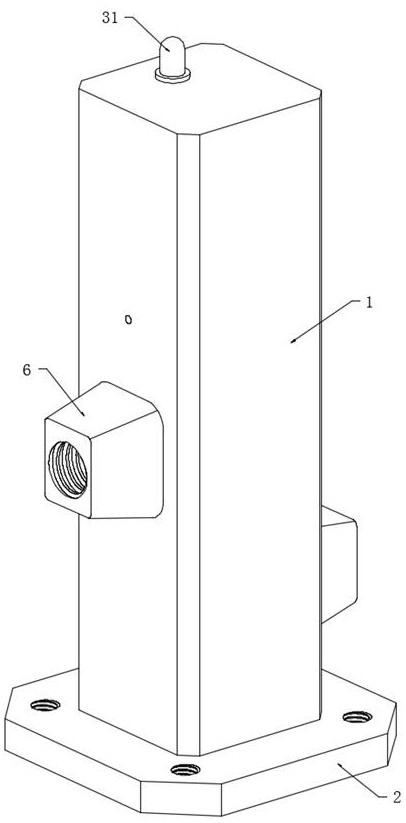

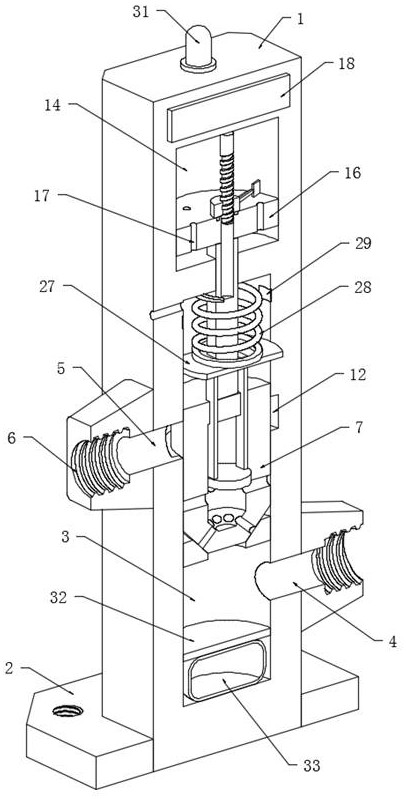

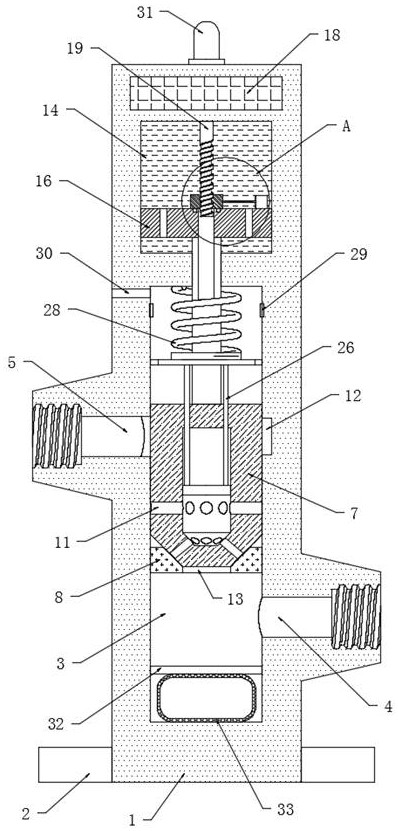

[0021] refer to Figure 1-5 , a hydraulic valve with a long service life, including a valve body 1, the lower end of the valve body 1 is fixedly connected with a mounting seat 2, a cylindrical valve cavity 3 is opened inside the valve body 1, and the outer wall of the valve body 1 is close to the lower end. A water inlet 4 is opened on the upper part to communicate with the valve cavity 3, and a water outlet 5 is opened in the middle of the outer wall of the valve body 1 away from the water inlet 4 to communicate with the valve cavity 3. The valve body 1 is located on the outer walls of the water inlet 4 and the water outlet 5. A connecting valve block 6 is fixed to the valve cavity 3 , a valve core 7 is sealed and slidably connected in the valve cavity 3 , and a constant pressure hole 30 is opened on the outer wall of the valve body 1 to communicate with the top cavity wall of the valve cavity 3 .

[0022] In the valve cavity 3, a baffle 8 is sealed and fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com