Carbon quantity regeneration monitoring method, device and equipment and storage medium

A carbon content and carbon load technology, which is applied in the fields of equipment and storage media, carbon content regeneration monitoring methods, and devices, can solve problems such as the inability of vehicles to monitor the regeneration process, avoid insufficient regeneration or waste of fuel, and improve monitoring accuracy. Effect

Pending Publication Date: 2022-08-09

DONGFENG LIUZHOU MOTOR

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The main purpose of the present invention is to provide a carbon regeneration monitoring method, device, equipment and storage medium, aiming to solve the technical problem that current vehicles cannot monitor the regeneration process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 example

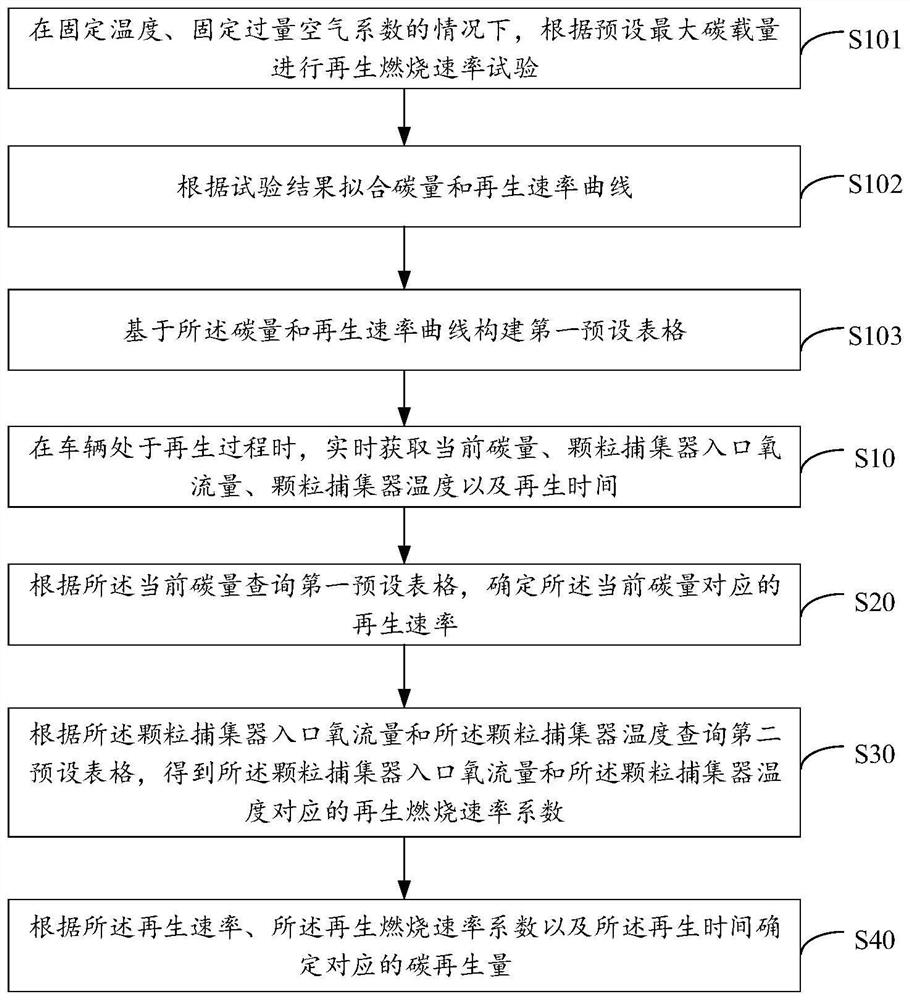

[0068] Based on the above-mentioned first embodiment, before the step S10, the method for monitoring carbon content regeneration in this embodiment further includes:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

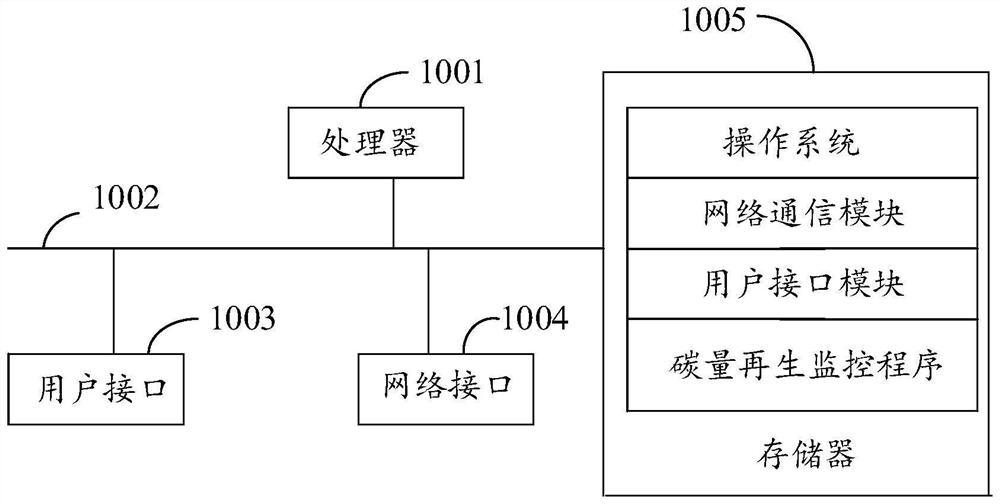

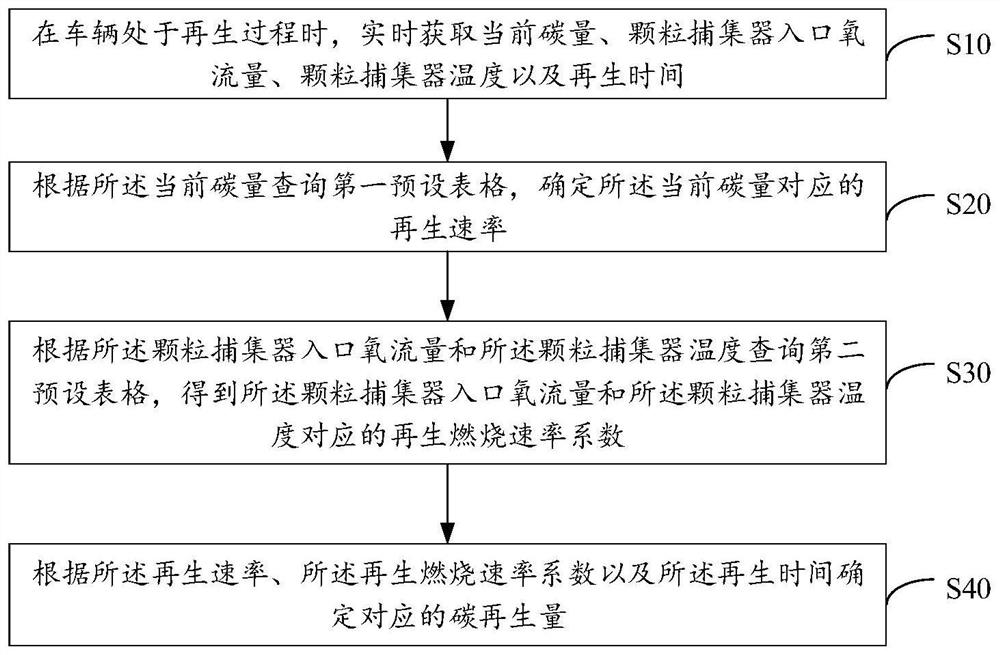

The invention belongs to the technical field of automobiles, and discloses a carbon regeneration monitoring method, device and equipment and a storage medium. The method comprises the steps that when a vehicle is in the regeneration process, the current carbon amount, the oxygen flow of an inlet of a particulate filter, the temperature of the particulate filter and the regeneration time are obtained in real time; querying a first preset table according to the current carbon amount, and determining a regeneration rate corresponding to the current carbon amount; querying a second preset table according to the oxygen flow rate at the inlet of the particulate filter and the temperature of the particulate filter to obtain a regeneration combustion rate coefficient corresponding to the oxygen flow rate at the inlet of the particulate filter and the temperature of the particulate filter; and determining the corresponding carbon regeneration amount according to the regeneration rate, the regeneration combustion rate coefficient and the regeneration time. By means of the mode, the regeneration process of the particulate filter is monitored, the influence of the current carbon amount of the particulate filter, the oxygen flow of an inlet of the particulate filter and the temperature of the particulate filter on the combustion rate is considered, and the monitoring precision of the carbon regeneration process is improved.

Description

technical field [0001] The invention relates to the technical field of automobiles, and in particular, to a method, device, equipment and storage medium for monitoring carbon content regeneration. Background technique [0002] The regeneration safety of GPF (particulate filter) is one of the most important links in the stable operation of the engine aftertreatment system, which is mainly affected by factors such as regeneration temperature control, carbon load during regeneration, and regeneration conditions. In order to ensure the normal operation of the vehicle system, it is necessary to monitor the regeneration process of the GPF. At present, after the GPF is regenerated, the residual carbon content is calibrated again through the differential pressure model, and the regeneration process cannot be monitored. [0003] The above content is only used to assist the understanding of the technical solutions of the present invention, and does not mean that the above content is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G16C20/10G16C20/90G06F16/903G07C5/08F01N9/00F01N3/023

CPCG16C20/10G16C20/90G06F16/903G07C5/0808G07C5/0825F01N9/002F01N3/023Y02T10/40

Inventor 秦琨兰江潘锦双黄国海

Owner DONGFENG LIUZHOU MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com