Antiprick bicycle wheel

A bicycle and anti-poke technology, which is applied in the direction of rims, vehicle parts, tire parts, etc., can solve the problems of cumbersome production of anti-leakage mechanism, inconvenient assembly and disassembly, etc., and achieve flexible and convenient disassembly and assembly, simple installation of steel wires, and comfortable riding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

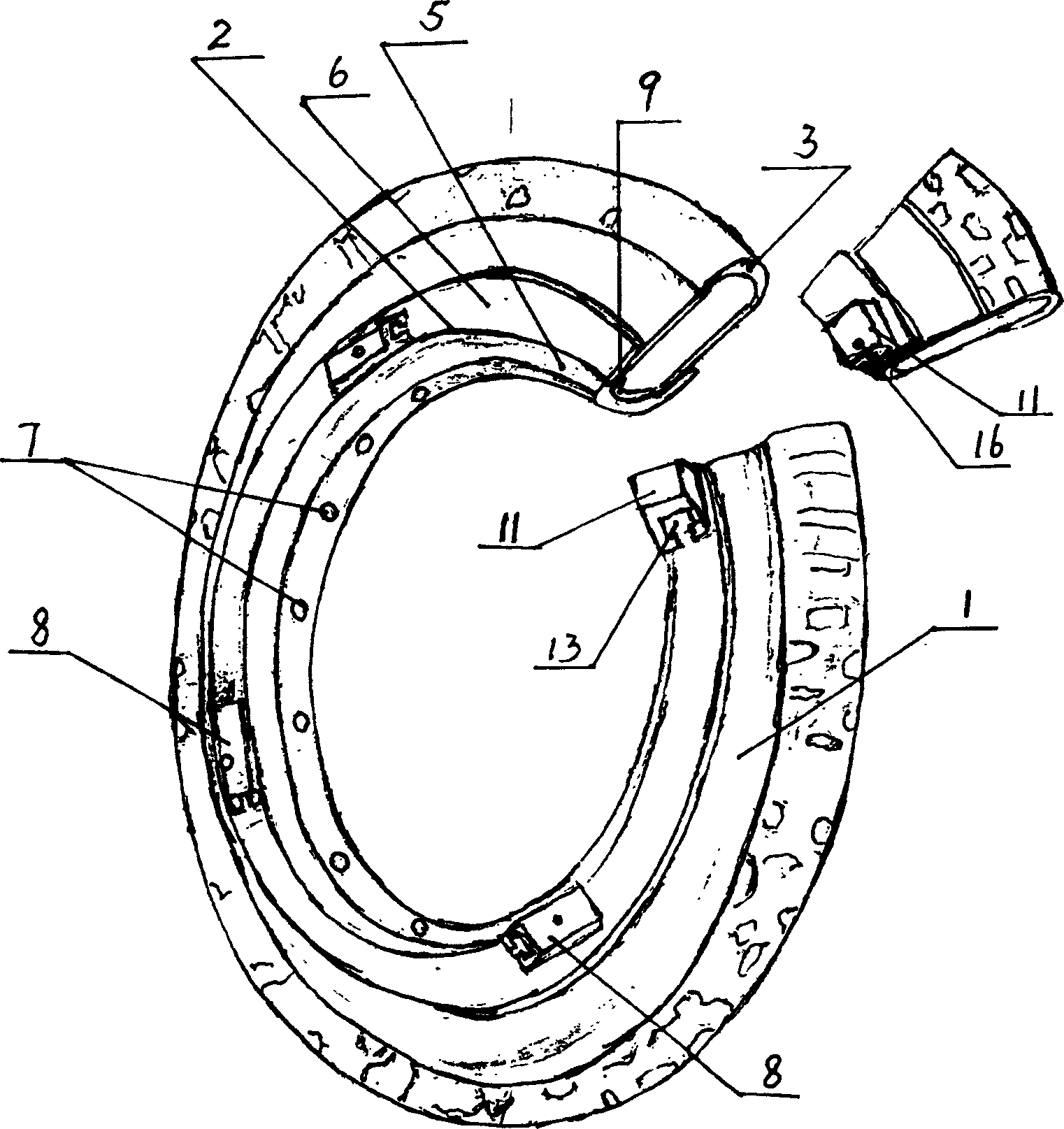

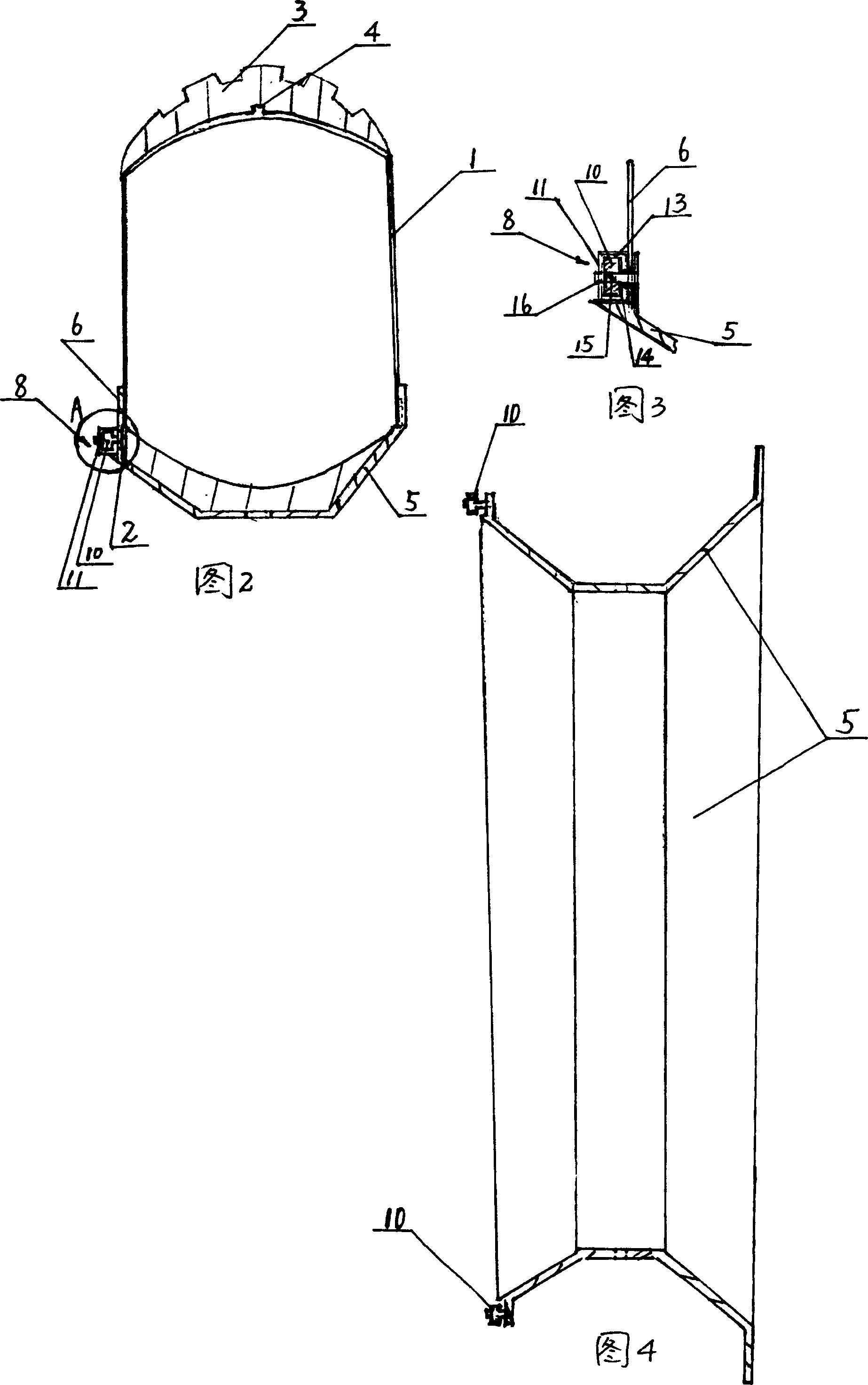

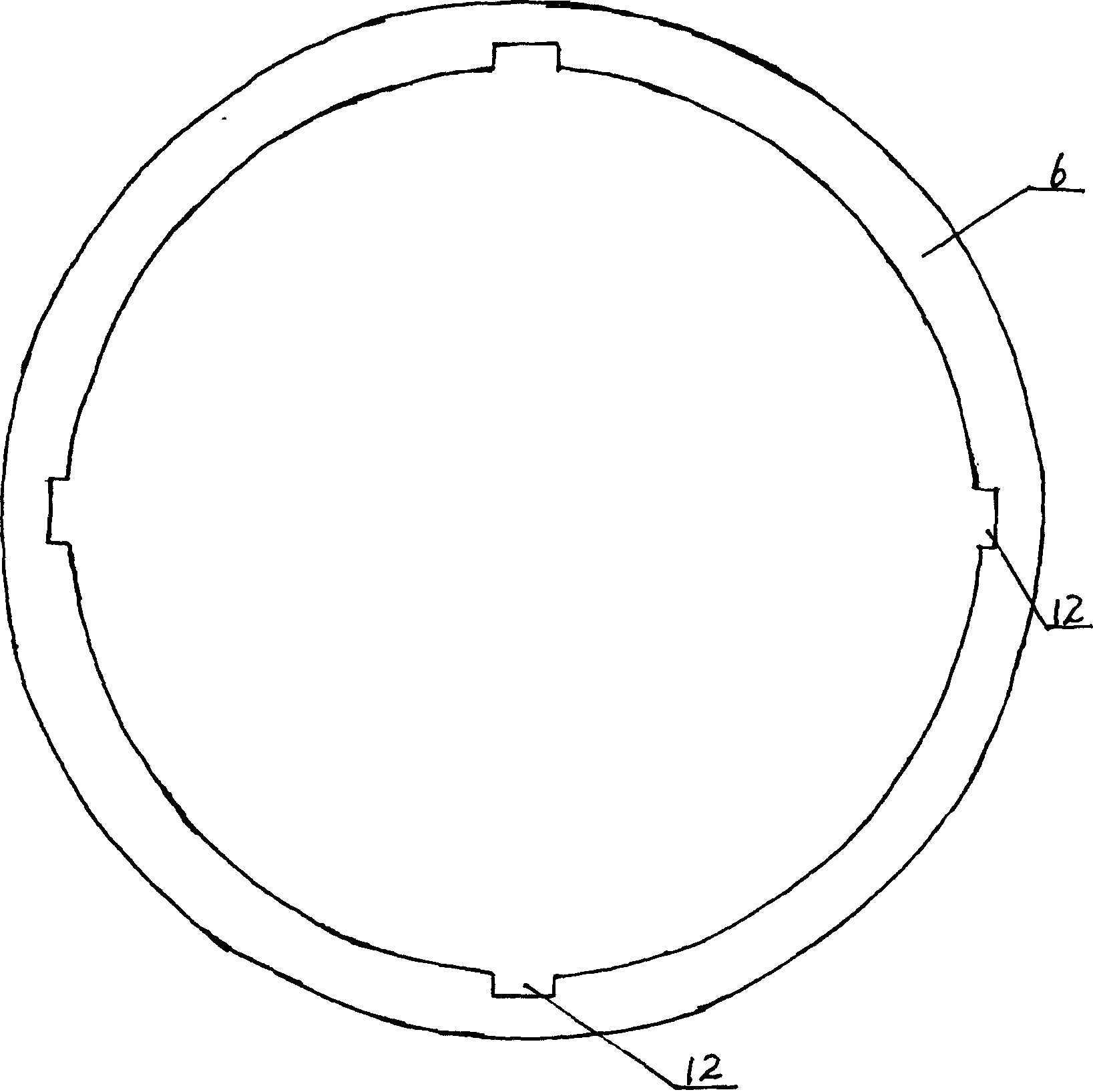

[0022] Such as Figure 1-6 , the anti-poking bicycle wheel of the present invention is still made up of cover tire 1, inner tube of a tire and steel ring 2 and spoke thereof, wheel axle (inner tube of a tire and spoke and wheel axle are not shown in the figure), the feature of the present invention is, cover tire 1 is that the section is inverted U There are high and low metal rings (preferably stainless steel) on the two sides of the type, and a circle of rubber layer 3 is tightly bonded to the surface of the upper end sealing surface. should. A plurality of positioning projections 4 are provided on the sealing surface of the upper end of the annular body of the tire 1, which are used to ensure reliable positioning with the rubber layer 3 and prevent the rubber layer 3 from shifting when degumming. Steel ring 2 is made of steel ring seat 5 and baffle plate 6, and steel ring seat 5 is the U-shaped metal annular body (preferably stainless steel material) that the cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com