Anti-corrosion anti-dry-grinding shaft seal

A shaft sealing, anti-dry wear technology, applied in the parts of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc. Leakage and other problems, to achieve the effect of simple sealing structure, saving manufacturing cost, convenient maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

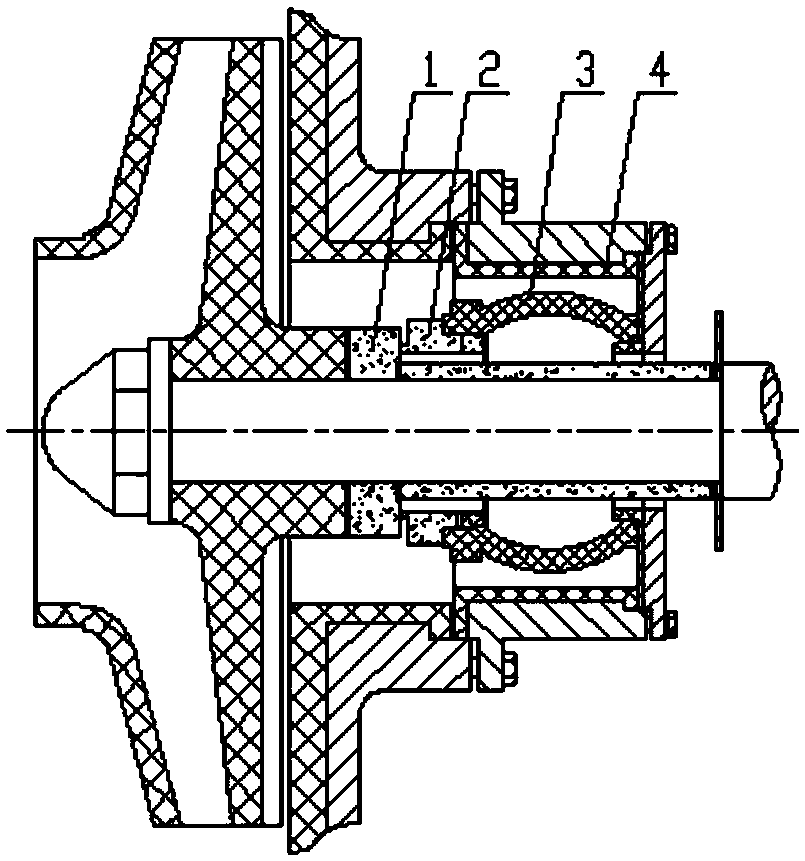

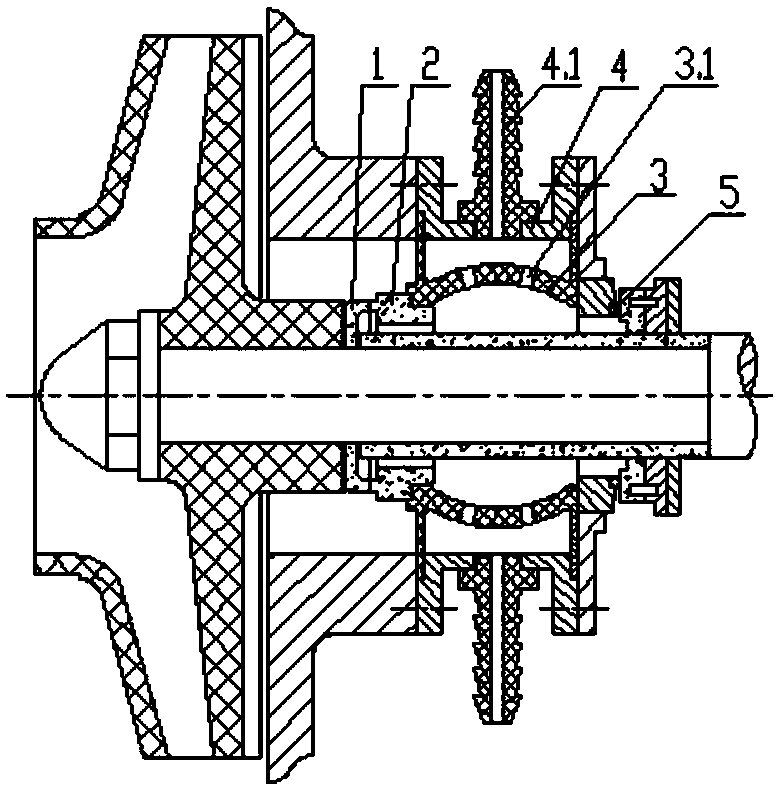

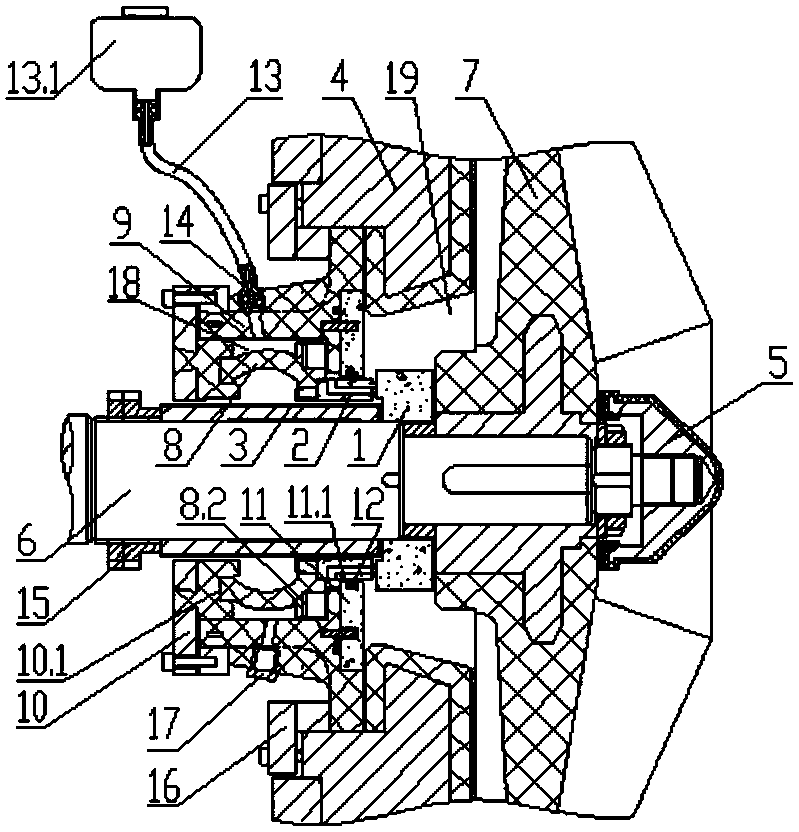

[0052] Example 1: as image 3 , 4 As shown, a kind of anti-corrosion and anti-dry grinding centrifugal pump, the shaft seal is installed on the main shaft 6 of the centrifugal pump, the impeller 7 is installed on the main shaft 6, the shaft seal includes a seal box assembly, a mechanical seal, and the mechanical seal includes a static ring 2, a moving ring 1. The sealing box assembly is fixed to the pump casing 4, the main shaft 6 is sleeved with a shaft sleeve 3, the moving ring 1 is clamped and fixed between the shaft sleeve 3 and the impeller 7, and the moving ring 1 is located in the pump cavity and is in contact with the conveyed material and liquid , the sealing box assembly includes a sealing box 9, a sealing box pressure rear cover 10 connected separately with the sealing box 9, a static ring push elastic ring 8 placed in the sealing box 9, and the sealing box pressure rear cover 10 is provided with an inlaid static ring top Push the concave-convex ring 10.1 of the el...

Embodiment 2

[0053] Example 2: as Figure 5 As shown, referring to Embodiment 1, other features remain unchanged, the static ring pushing elastic ring 8 is a straight cylindrical shape with corrugations, and a steel compression ring 20 is provided internally.

Embodiment 3

[0054] Example 3: as Image 6 As shown, referring to Embodiment 1, other features remain unchanged. The outer peripheral surface of the rigid partition plate 58 is provided with two annular grooves, and an O-ring and a lip-shaped sealing ring are arranged in the annular groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com