Bendable blades of a hydrodynamic self-pitching turbine

A curved blade, hydrodynamic technology, applied in the directions of hydropower, engine components, machines/engines, etc., can solve the problems of cable winding, high failure rate and complex structure of the generator set, and achieve low cost, high mechanical strength and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

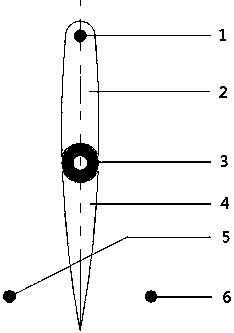

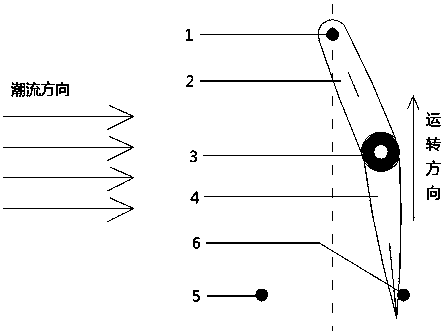

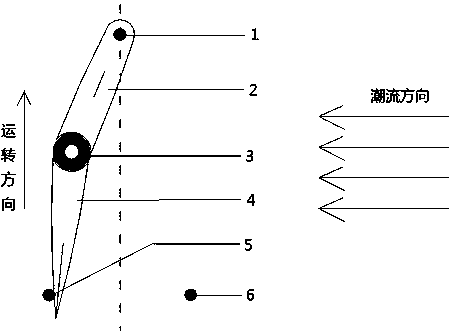

[0016] figure 1 is the position state of the bendable blade on the central axis. The blade installation shaft 1 is located at the front end of the bendable blade. The blade installation shaft 1 can be fixed to the hub of the tidal energy turbine blade. The blade is divided into two parts, the front part 2 and the tail part 4. The blade can swing left and right around the blade installation rotating shaft 1. The front part 2 of the blade and the tail part 4 of the blade are linked together by the large rotating shaft 3 in the middle of the blade. The angle between 2 and blade tail 4 will not be less than 150 degrees. When reaching 150 degrees, due to the limit, the blade front portion 2 and the blade tail portion 4 will touch together, so the rotation will stop. On the left and right sides of the lower end of the blade tail part 4, there are left limit post 5 and right limit post 6 fixed with the turbine to limit the swing angle of the blade. When the flow comes from the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com