Hoisting and transport device extracting article from local high temperature area

A local high-temperature, transportation device technology, applied in the field of mechanical devices, can solve the problems of low reliability, high cost, inappropriate grasping, lifting, and conveying workpieces, etc., to achieve the effect of avoiding empty grasping and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

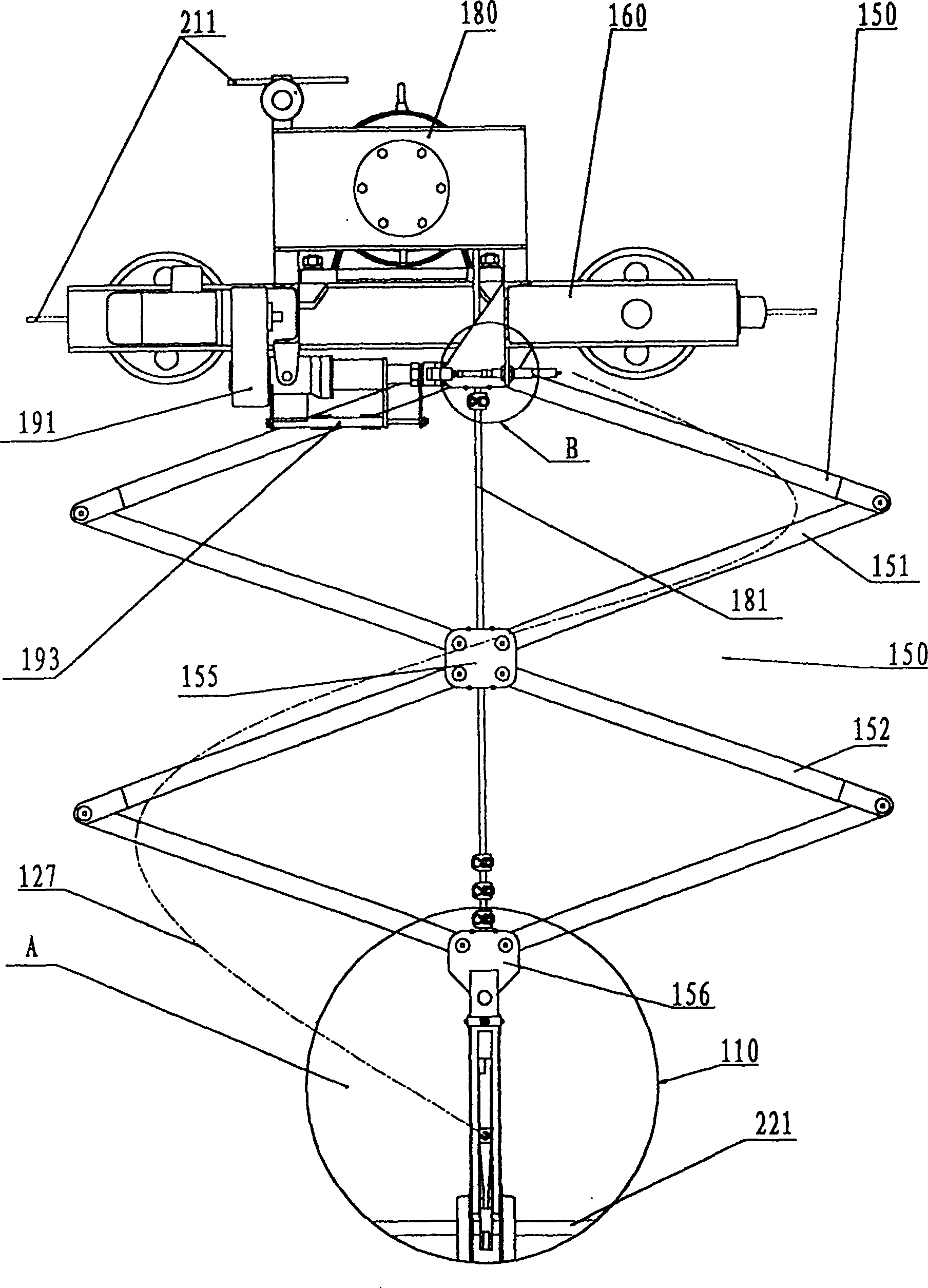

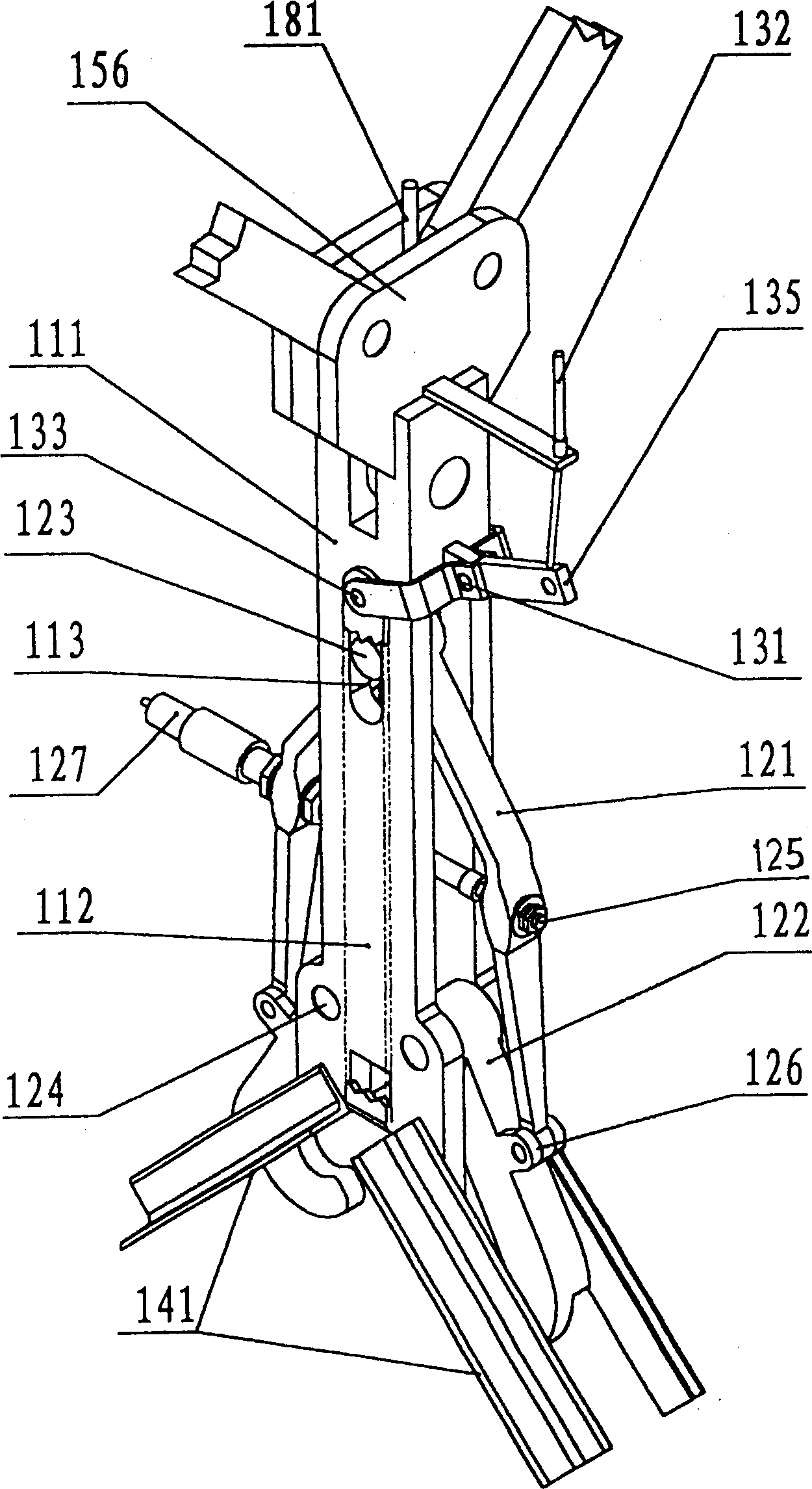

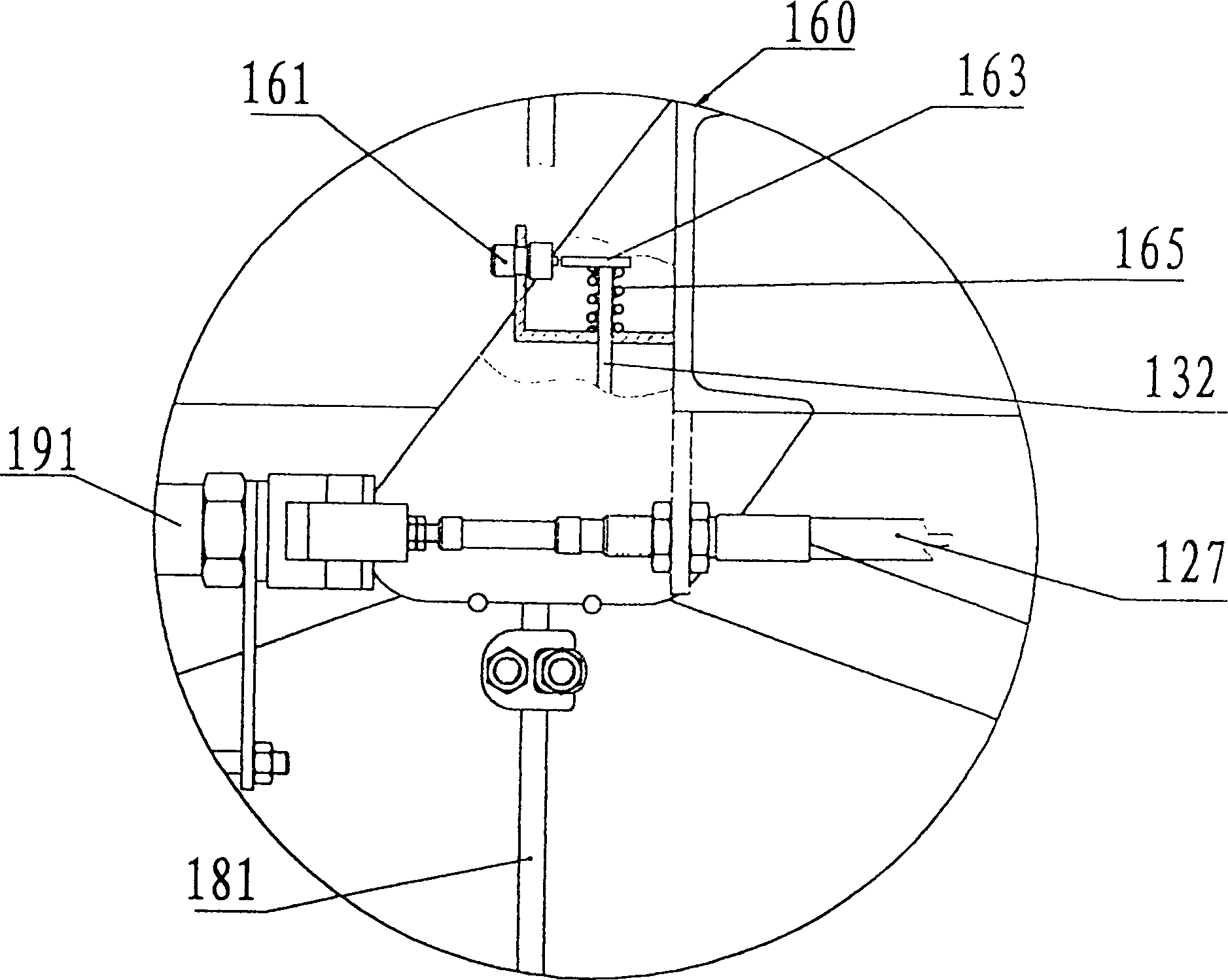

[0020] See first figure 1 , figure 2 with Figure 4 , Figure 5 The lifting and transporting device of the present invention includes a transport track 231, a frame 160 walking on the transport track, a lifting component 180 installed on the frame, and a manipulator 100 with a metal structure suspended under the frame 160. The manipulator 100 includes a link arm 150 and a grasping hand 110 connected up and down. The link arm 150 is two plane four-link mechanisms 151 and 152 connected by a connecting block 155. The upper end of the link arm 150 is connected with the frame 160, and the lower joint 156 at the lower end is connected with the gripper 110. The wire rope 181 in the lifting component 180 passes through the connecting block 155 of the link arm and is connected to the lower end of the planar four-bar linkage 152. The grab hand 110 includes an arm 111 and a grab hook 122, and a grab hook opening and closing mechanism composed of a bent connecting rod 121, a grab hook 122, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com