Automatic instant noodle bowl feeding equipment applying manipulator

A technology of manipulators and instant noodles, which is applied in the field of packaging, can solve the problems of vertical bowls not being right, shutdown, bowl dropping, etc., and achieve the effect of not easy to block the bucket, high efficiency, and low bucket dropping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

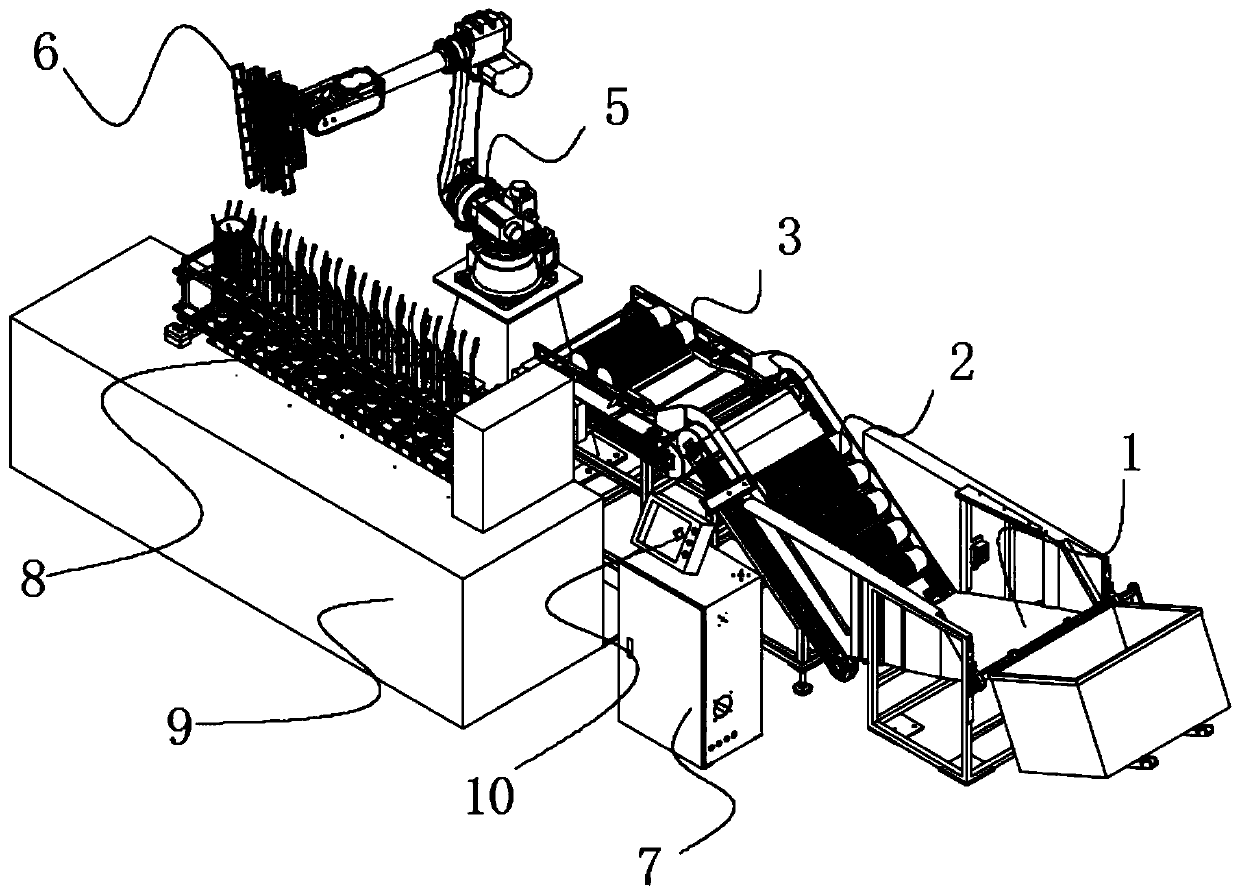

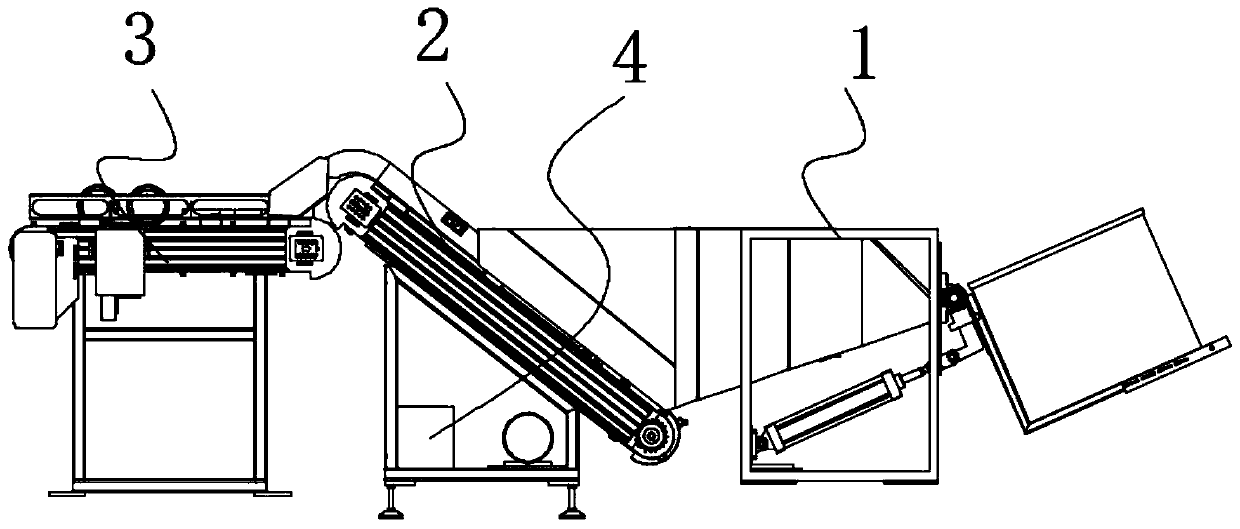

[0062] like figure 1 and figure 2 As shown, an instant noodle bucket automatic bucket loading equipment using a manipulator, including a discharge table 1 for placing materials, a climbing conveying mechanism 2, a horizontal conveying mechanism 3, an electric control climbing conveying mechanism 2 and a horizontal conveying mechanism 3 Electric control cabinet 4, manipulator 5 for gripping materials, main electric control box 7 for electrical control manipulator 5, human-computer interaction screen 10 for adjusting parameters and operating and controlling the action of manipulator 5, and discharging table 1 is set on climbing conveying mechanism 2 The incoming material side of the climbing conveying mechanism 2 is set on the incoming material side of the horizontal conveying mechanism 3, the manipulator 5 is set on the feeding side of the horizontal conveying mechanism 3, and the movable end of the manipulator 5 is provided with a manipulator claw 6, and the manipulator 5 On...

Embodiment 2

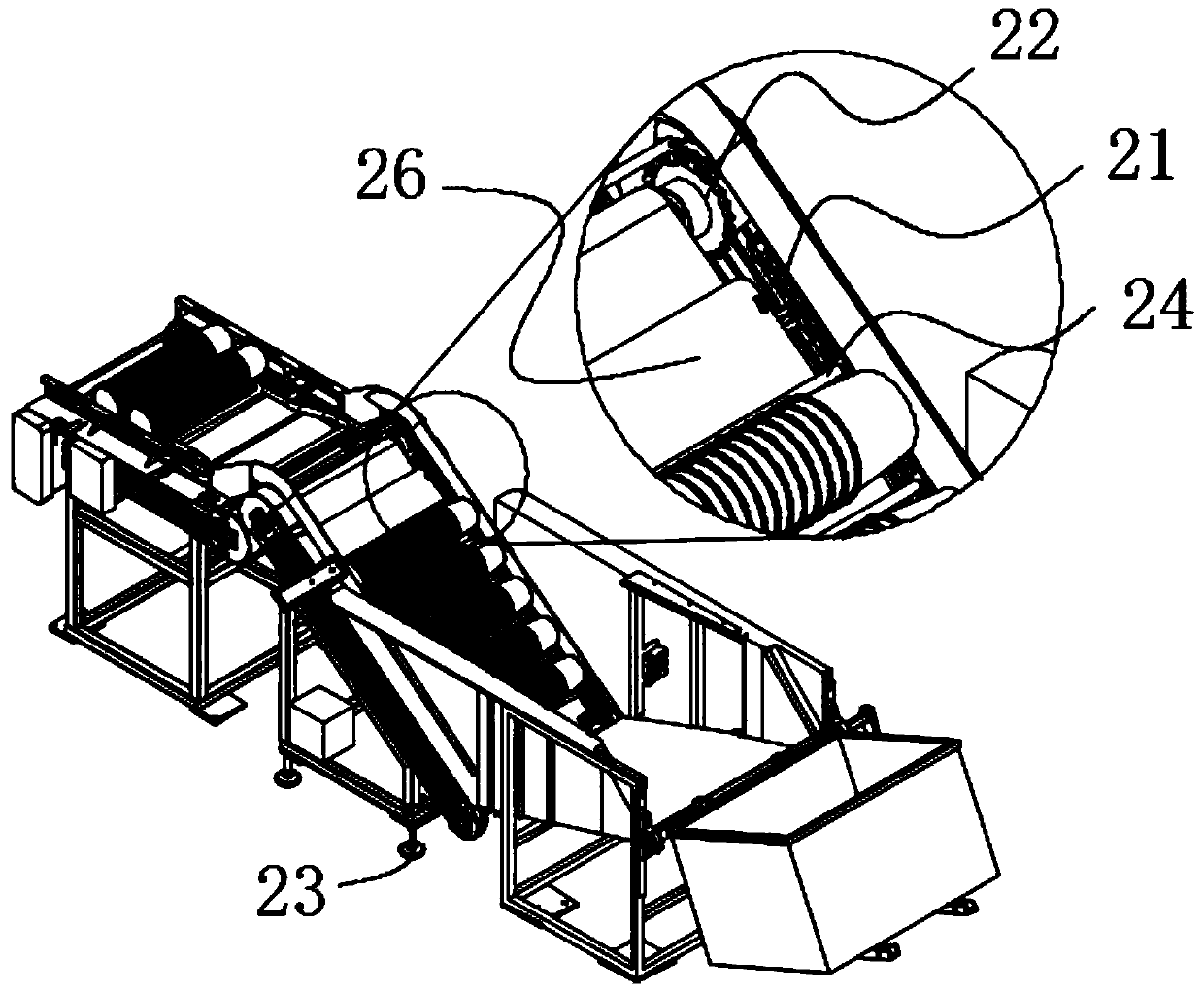

[0065] like image 3 and Figure 4 As shown, on the basis of Embodiment 1, the climbing conveying mechanism 2 includes two climbing driving wheels 22 arranged in parallel, two climbing driven wheels 23 arranged in parallel, a climbing chain 21, a climbing rod 24 and driving The climbing motor 25 that the climbing driving wheel 22 rotates has two climbing chains 21, and the climbing driving wheel 22 and the climbing driven wheel 23 are driven by the climbing chain 21, and the two ends of the climbing rod 24 are respectively connected to the two Two climbing chains 21 are connected, and a climbing base plate 26 is provided between the two climbing chains 21 .

[0066] The distance between the climbing rods 24 is greater than the diameter of the instant noodle bucket, so the instant noodle bucket can be stuck between the climbing rods 24, and the climbing base plate 26 supports the instant noodle bucket so that it can be moved with the rotation of the climbing rod 24. Lifting, ...

Embodiment 3

[0068] On the basis of Embodiment 2, the climbing chain 21 is a roller chain or a toothed chain.

[0069] The advantage of the roller chain is that it is simple in structure, easy to maintain, and convenient to install the climbing pole 24; the advantage of the toothed chain is that it has higher transmission precision, lower noise and is more durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com