Miniatrized hydraulic electronic pump and its manufacture

A process method and electronic pump technology, applied in the direction of liquid variable capacity machinery, pumps, pumps with flexible working elements, etc., can solve the problems of poor positioning of ball valves, poor working stability, easy pressure relief, etc., and increase output power , Good consistency, unobstructed liquid in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

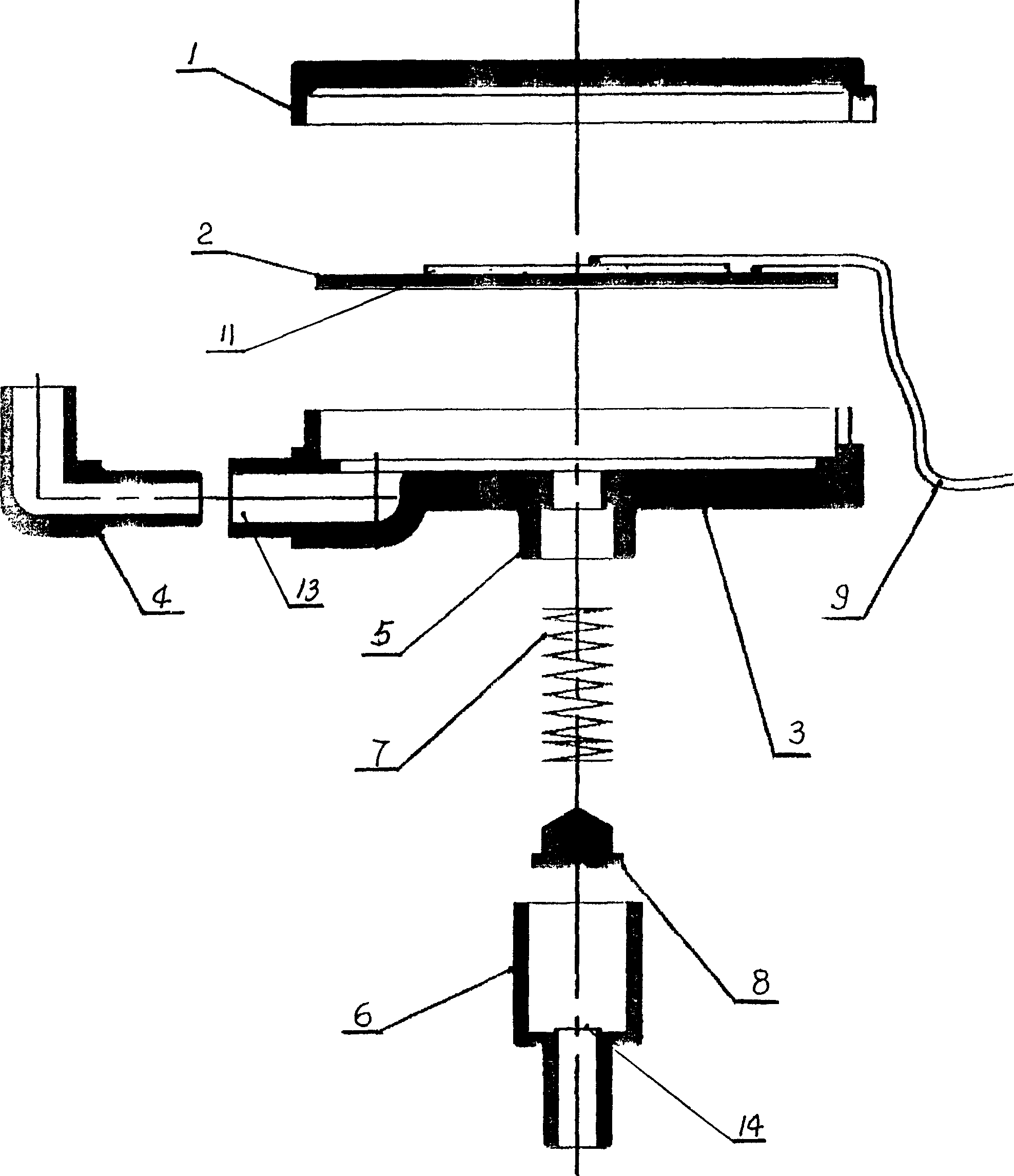

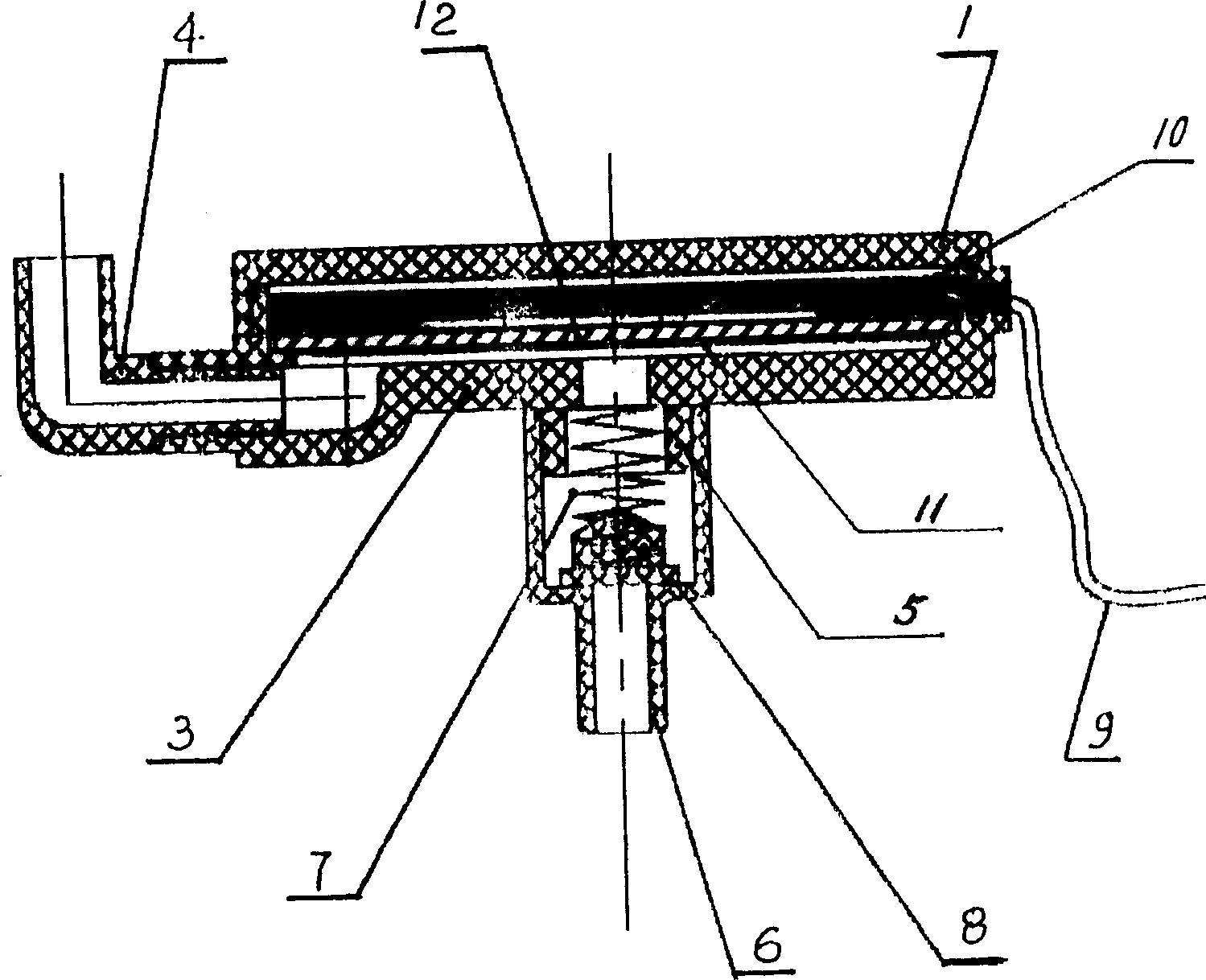

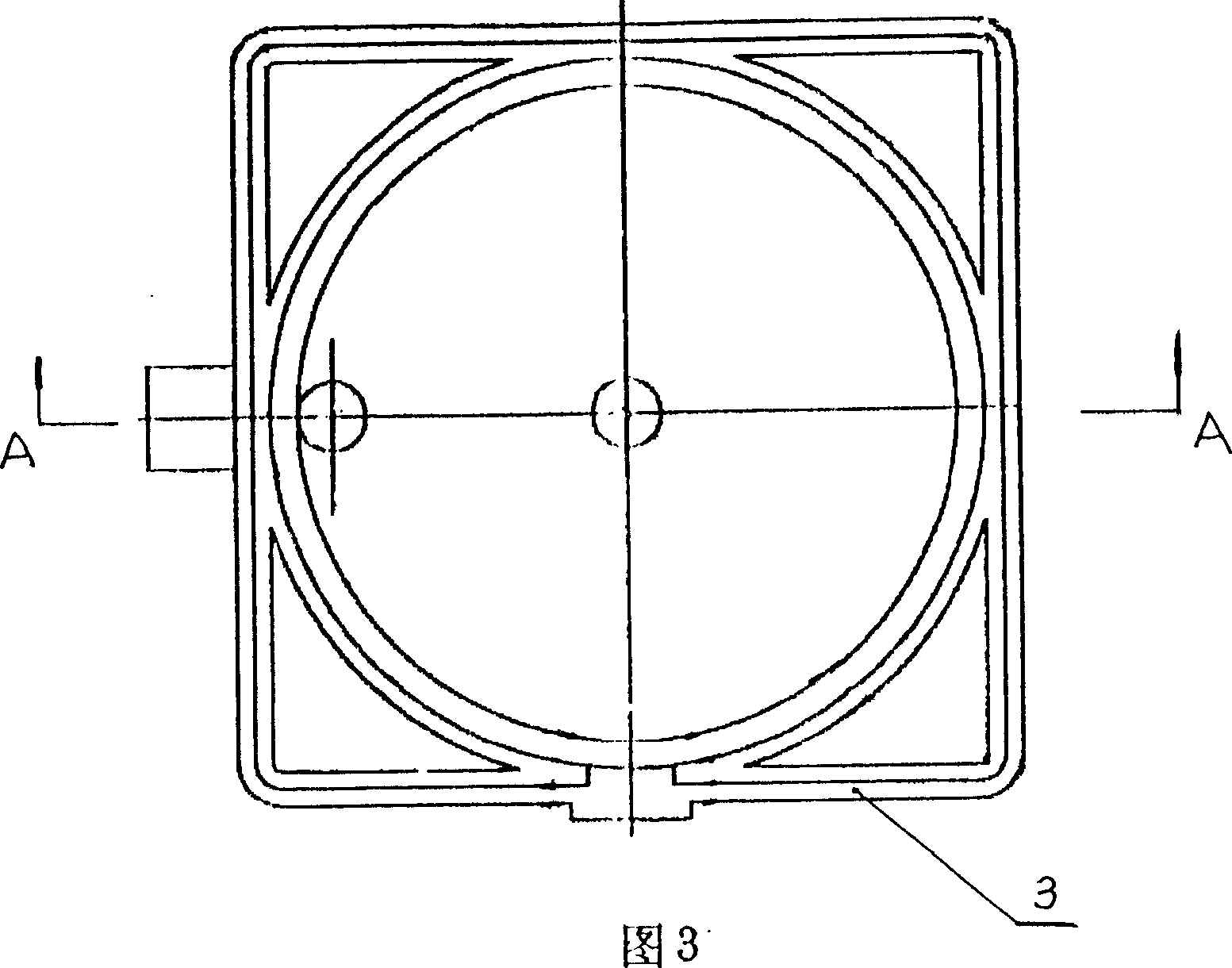

[0013] The following is a further detailed description according to the attached drawings: see figure 1 with figure 2 , The whole process and structure are: the concave cavity on the upper side of the pump body 3 and the pump cover 1 form a pump cavity, there is a liquid inlet 5 in the middle under the pump body 3, and a liquid outlet 13 on the left. The piezoelectric ceramic transducer 2 is customized by the manufacturer or purchased on the market. Its parameters are high voltage 220V, 50Hz; 120V, 60Hz and low voltage below 42V, 50Hz or 60Hz, according to the user's requirements for the product. A piece of piezoelectric ceramic transducer sheet 2 is used (it can also be called the energy sheet 12 as usual, but in order to distinguish the energy sheet 12 composed of a plurality of piezoelectric ceramic sheets 16 and a piece of substrate 15, the piezoelectric ceramic sheet is replaced by the energy sheet 12 in the present invention. The name of the energy sheet 2 remains unchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com