Composite nose prosthesis

A nasal prosthesis and composite technology, applied in the field of nasal prosthesis, can solve the problems of high price, inconvenient use, and difficult to promote.

Inactive Publication Date: 2004-07-14

叶明

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this way, the operation time is prolonged and the process is more complicated. At the same time, because the material is too soft, it is very difficult to put it in the operation, and it is very inconvenient to use; moreover, it is expensive and difficult to promote.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

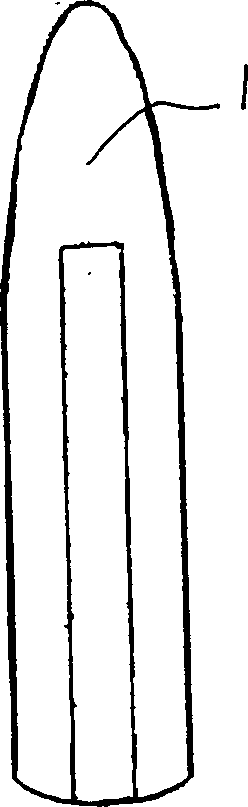

[0004] attached figure 1 It is the front view of the present invention.

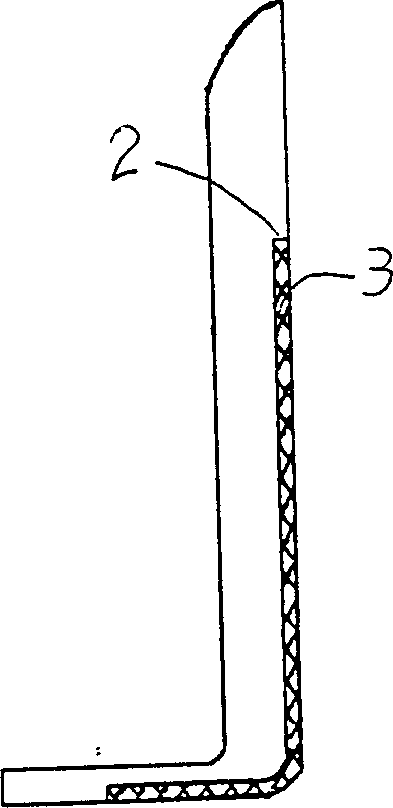

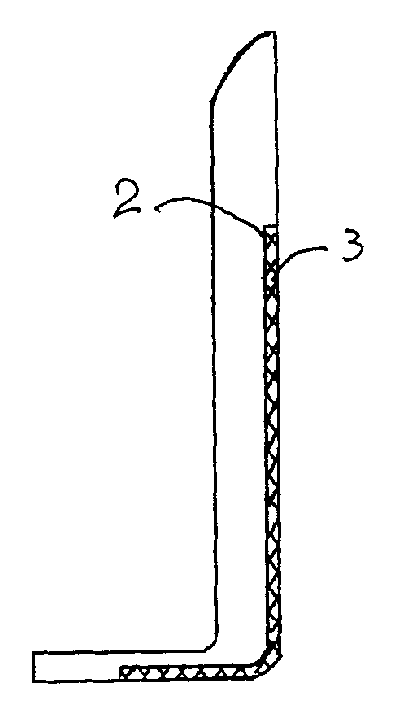

[0005] attached figure 2 is attached figure 1 side view.

[0006] 1 back of the nose, 2 slots, 3 strips (blocks).

[0007] The composite nasal prosthesis is L-shaped made of solid silicone rubber material, and a long groove 2 is opened on the back of the nose 1 of the L-shaped. Long body 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The composite type nasal prosthesis is characterized by that the back of nose of L-type or lance-type prosthesis made of solid silicone rubber material has an enlongated slot, a long strip body which is made of bulky teflon material and correspondent to the enlogated slot. The present invention adopts the bulky teflon material with excellent compatibility with human body tissue in the key position-back of nose and apex of nose, after said material is implanted into human body, the human self-body tissue cell can be grown into bulky teflon material, so that it can effectively prevent the material from producing rejection, motion and ulceration, etc. at the same time it also can prevent light reflex, and can make the plasticized face form more natural and lifelike. The solid silicone rubber bose as base seat has a certain hardness, its cutting process is simple, and its implantation is more convenient, and its cost is low.

Description

Technical field: [0001] The invention belongs to the nasal prosthesis used for facial plastic filling, in particular to the improvement of the structure of the nasal prosthesis. Background technique: [0002] At present, the most widely used nasal prosthesis materials for facial plastic filling are silicone rubber products and expanded polytetrafluoroethylene material products. The nasal prosthesis made of silicone rubber material has an L-shaped structure. For silicone rubber products, because the material is too stiff, the natural feeling is often not ideal; and after the silicone rubber nasal prosthesis is implanted in the human body, the healing method with human tissue is fiber wrapping, so that as time goes by, the nasal prosthesis There is a possibility of movement and rupture in the human body; after some people have implanted nasal prosthesis, the back of the nose of the nasal prosthesis will reflect light, making the appearance look very unnatural; and because Hu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A61F2/18A61L27/14

Inventor 叶明

Owner 叶明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com