Variable inductor element

An inductive element, variable technology, applied in the direction of electrical components, variable inductance/transformers, inductors, etc., can solve the problems of increasing the wrong cutting of the horizontal strip 71b, narrowing the interval of the horizontal strip 71b, and difficulty in adjusting the inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

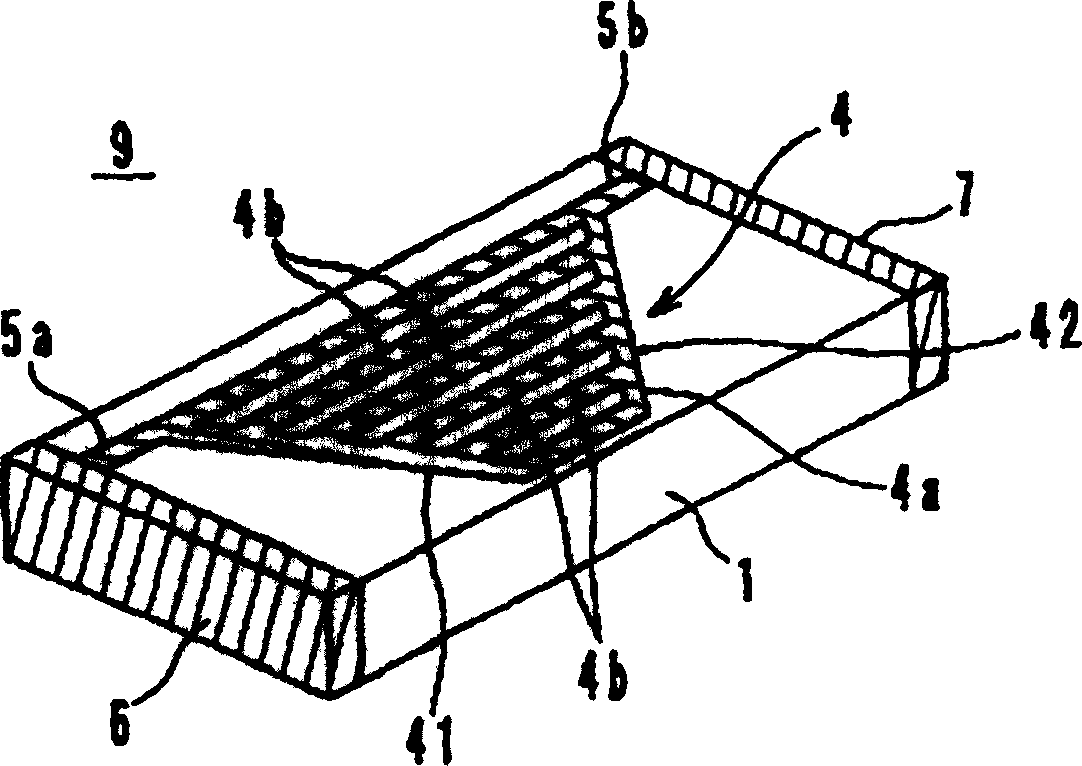

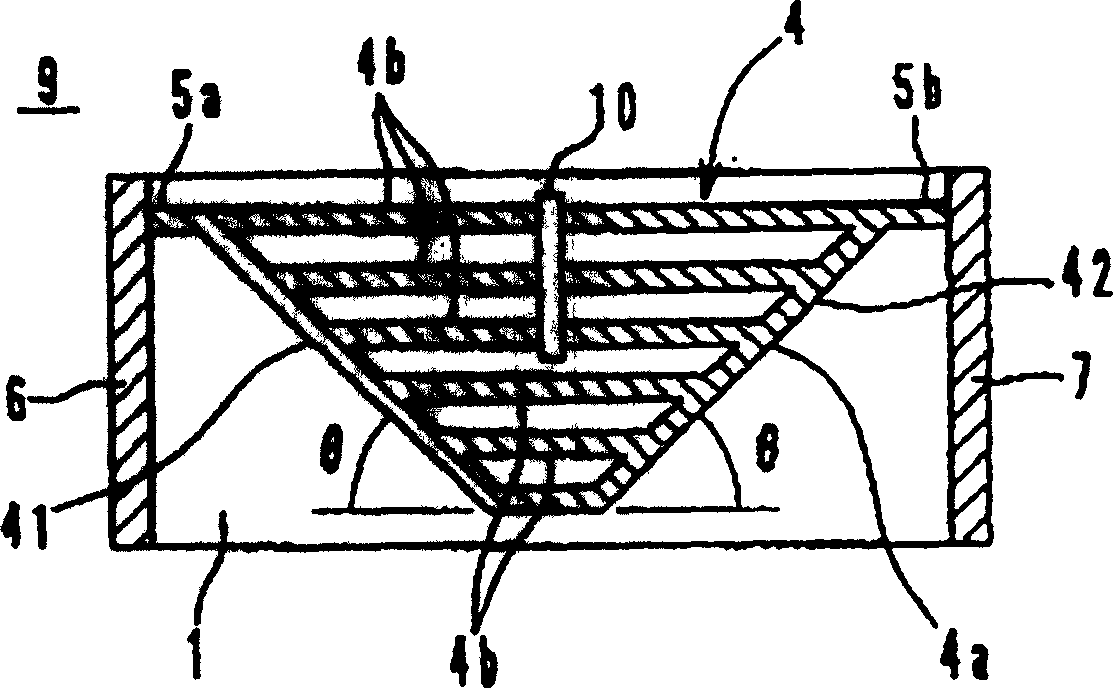

[0019] Embodiments of the variable inductance element of the present invention will be described below with reference to the drawings.

[0020] like figure 1 As shown, after the upper surface of the insulating substrate 1 is ground to a smooth surface, the inductor pattern 4 is formed on the upper surface of the insulating substrate 1 using a thick film printing method or a thin film forming method such as photolithography or the like. According to the thick film printing method, a mask with openings at the desired pattern is made, covered on the upper surface of the insulating substrate 1, and an electrically conductive paste is applied from the top of the mask, so that the openings through the mask A conductor having a relatively large thickness is formed on the exposed upper surface of the insulating substrate 1 in a desired pattern (inductor pattern 4 in this embodiment).

[0021] An example of photolithography will be described below. A relatively thin conductive film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com